Assembly and connection strategies for optical fibres with photonic integrated circuits (PICs) are usually implemented using adhesives. However, this can lead to optical degradation in the long term and thus to high optical transmission losses. This would be fatal for critical applications, such as in medical technology and life science. Together with industrial partners, researchers at Fraunhofer IZM have developed an adhesive-free, space-saving and robust laser welding process for fixing optical fibers to PICs as part of the Eurostars project 'PICWeld'.

Dr. Alethea Vanessa Zamora GómezDesignand interconnection strategies of optical fibers on photonic integrated circuits (PICs) are usually realized with adhesives. But this can lead to optical degradation and thus to high optical transmission losses. For critical applications, such as in medical technology and life science, this would be fatal. Teaming up with industry partners, researchers at Fraunhofer IZM developed an adhesive-free, space-saving and robust laser welding process for fixing optical fibers to PICs as part of the Eurostars project 'PICWeld'.

Dr. Alethea Vanessa Zamora GómezDesignand interconnection strategies of optical fibers on photonic integrated circuits (PICs) are usually realized with adhesives. But this can lead to optical degradation and thus to high optical transmission losses. For critical applications, such as in medical technology and life science, this would be fatal. Teaming up with industry partners, researchers at Fraunhofer IZM developed an adhesive-free, space-saving and robust laser welding process for fixing optical fibers to PICs as part of the Eurostars project 'PICWeld'.

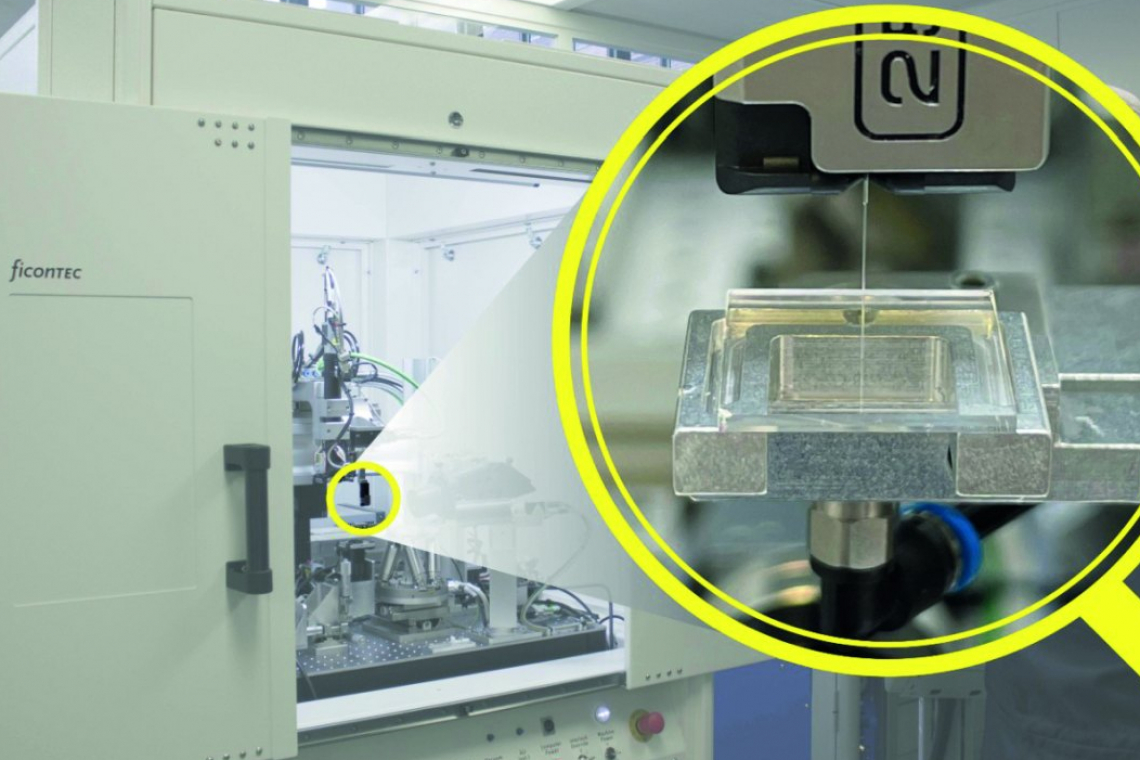

As part of 'PICWeld', researchers at the Fraunhofer Institute for Reliability and Microintegration (IZM), together with partners LioniX International BV, Phix Photonics Assembly and ficonTEC Service GmbH, developed the adhesive-free, space-saving and robust laser welding process. By integrating the process into an automated alignment system, the industrial maturity of the system was also demonstrated. "This makes the glass-glass bonding technology very attractive for commercial use," says Dr. Alethea Vanessa Zamora Gómez, who heads the project team at the IZM and is the technical contact person.

It has long been known that biochemical processes ranging from organ functions and temperature regulation to hormone production are significantly influenced by light. Research into light and the body is now well advanced, with young disciplines such as life science and biophotonics addressing issues at the intersection of the natural sciences and medicine. High-precision and complex measurements can be used to obtain information on how light and matter interact, for example when investigating the structure of cells and tissues that are relevant to cancer.

Insights into biological and chemical processes

However, gaining insights into the innermost workings is no easy task: Recently, miniaturized systems based on photonic integrated circuits with highly stable fibre connections have been proposed to understand the role of visible light in biological processes. This is precisely where the IZM came in with the BMBF-funded Eurostars project. The researchers developed the completely new laser welding process, with which optical fibers can be welded directly to PICs on quartz glass. With the help of partner ficonTEC Service GmbH, this process was implemented in an automated system that offers high reproducibility and scalability.

The research team led by Dr. Zamora Gómez has set itself the task of making glass-glass joints simpler, more robust and more durable. Such connections are already used in the world of optics, but conventional solutions have a significant disadvantage: In most cases, the discrete optical components are joined with an adhesive. Due to the softness of the adhesive, the position of the component can change over time, and it also represents an interference point between the two glass layers, which can cause attenuation of the signal and become brittle as the adhesive ages. Long-term stability is therefore often critical. In order to overcome these disadvantages of the joining technology, the researchers have developed aCO2 laser welding process and are thus realizing a direct, thermally robust and transparent glass-glass connection for the first time.

Automated process system developed

However, in order to not only experiment with laser welding for reliable quartz glass joints, but to bring it one step closer to industrialization and high scalability, a completely new, automated process system was developed and manufactured.

The resulting system enables adhesive-free and polarization-maintaining, highly efficient coupling between optical fused silica fibres and fused silica PICs with integrated waveguides. However, the researchers had to overcome a number of technological challenges before they were able to realize connections suitable for application. Because glass fibers and the substrates have different volumes, the heat capacities of the two joining partners are also unequal. This discrepancy results in very different heating and cooling behavior, which can lead to deformations or cracks during cooling, for example. The solution of the photonics experts was to preheat the substrate homogeneously using a separate and individually adjustable laser, so that the melting phase of the fiber and the substrate is nevertheless reached simultaneously.

The system, equipped with thermal process monitoring up to 1300°C, a positioning system accurate to 1µm, image recognition processes and control software, welded the first joints during the course of the project so that its functionality could be tested and initial process-oriented measurements carried out.

Following the completion of PICWeld in 2021, the first follow-up projects in which the new technology was used for fiber coupling of collimators, waveguide chips and multi-lens arrays were carried out seamlessly. "With our system forCO2 laser welding, we have expanded the previous process principle: the high automation potential in particular enables customers to use PICs with maximum coupling efficiency. Integrated in industry, this means a leap forward for the application areas of biophotonics, but also quantum communication and high-performance photonics," explains project manager Dr. Alethea Vanessa Zamora Gómez.

Fraunhofer IZM's contribution to PICWeld was funded by the German Federal Ministry of Education and Research (BMBF) under grant number 01QE1744C. It is part of the Eurostars program (11324), which includes a collaboration with Lionix International BV, Phix Photonics Assembly and ficonTEC Service GmbH.