In future, grey box models will make it possible to detect any signs of wear or manipulation in electronic systems at an early stage before a failure occurs. The new process is being developed and tested for the first time using the example of safety-critical applications in the automotive and rail sectors. However, the basic principle can also be transferred to many other areas of application.

In the future, grey box models will make it possible to detect any signs of wear or manipulation in electronic systems at an early stage before an actual failure occurs. The new method is being developed and tested for the first time using the example of safety-critical applications in the automotive and rail sectors. However, the basic principle can also be transferred to many other areas of application.

Introduction

Reliability has always been one of the most important criteria in automotive and rail technology, especially with increasing system complexity involving several physical subsystems. This high complexity favors the vulnerability of the design process to failures, which are considered a major threat to reliable systems. The failure of a single component or subsystem can have catastrophic consequences. In addition, the time-consuming development, which requires many iterations, and the associated costs are major limitations when it comes to describing complex dynamic systems. Modeling and simulation are therefore becoming increasingly important in order to implement predictive approaches for estimating degradation and end-of-life.

Model-based forecasting approaches are based on physical models that describe the relationships between external loads, system behavior and components. These models must take into account the various damage processes that occur simultaneously in a component. Each of these damage and wear processes contributes to the overall degradation of the system. In addition, model-based prediction approaches utilize domain-specific knowledge about a system, its components and failure causes or modes through the use of physics-based models that capture the underlying physical phenomena.

An increasingly important term in the field of simulation of physical systems is the concept of the 'digital twin'. This is a digital representation and modeling method that can be used to extend and improve the life cycle of complex electronic systems and processes. Digital twin technology has become an important area of research worldwide. Digital twins can also be used to monitor fatigue, anomalies, deformations and the reliability behavior of systems under external loads by creating a digital fingerprint that proactively responds to aging-related wear and safety-critical changes. Modeling a digital twin requires a comprehensive understanding of the entire system and the use of dynamically composed models consisting of individual component models. The modeling must also be done at an appropriate level of detail in order to obtain an accurate representation of the digital twins and reliable simulation results. Another factor to consider is that the process of creating digital twins undergoes a continuous optimization process in order to reach different stages of development and reduce the level of risk. At the same time, the system behavior in the field and the simulation results can be analyzed and used to check and improve both the virtual model and the real system.

In order to couple and simulate the submodels of the digital twin, it is essential to use various specialized tools for modeling in the respective disciplines due to the diverse areas of application and the large number of different development tasks. The integration of different tools into a common simulation environment can lead to problems with regard to data compatibility and software connection. The Functional Mock-up Interface (FMI) standard therefore forms a solid basis for this problem and is well known in the automotive sector.

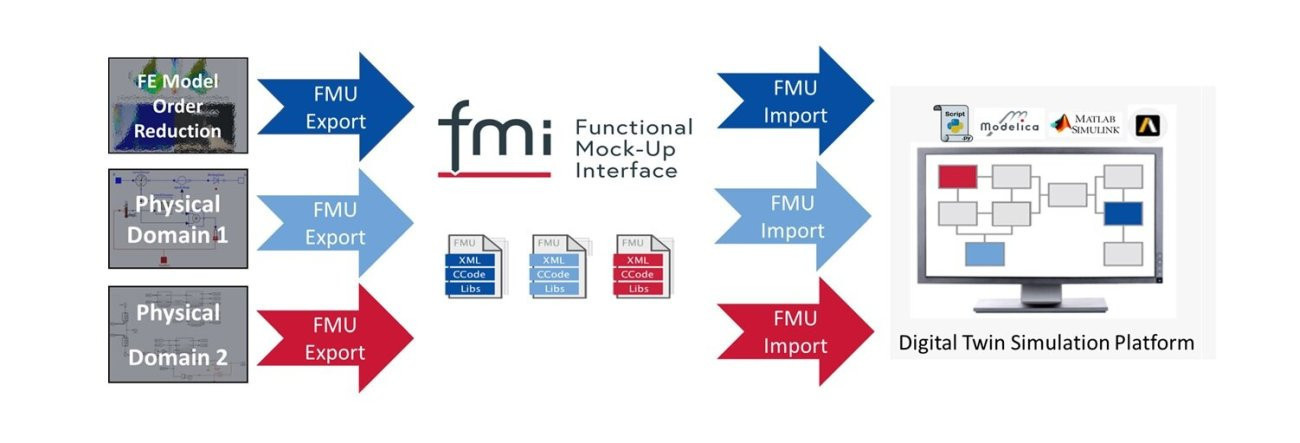

At the Fraunhofer Institute for Reliability and Microintegration (IZM), approaches for multidomain system modeling are being developed as part of the publicly funded project SesiM (self-validation of complex electronic systems in safety-critical mobility applications based on greybox models) to evaluate the degradation behavior of the system in the field under external loads. The approaches include a mission profile-based multidomain modeling approach to evaluate electronic systems and their degradation behavior. This approach is used to implement digital twins by creating Functional Mock-up Units (FMUs) of the individual domains from different simulation tools using the FMI toolbox, which can be coupled and simulated within a digital twin simulation platform (such as Modelica, Matlab/Simulink or Ansys Twin Builder) based only on their input and output parameters and without dependence on their internal structure, comparable to a black box(Fig. 1).

Fig. 1: Graphical representation for the creation of digital twins for multidomain systems with FMI

Fig. 1: Graphical representation for the creation of digital twins for multidomain systems with FMI

concept

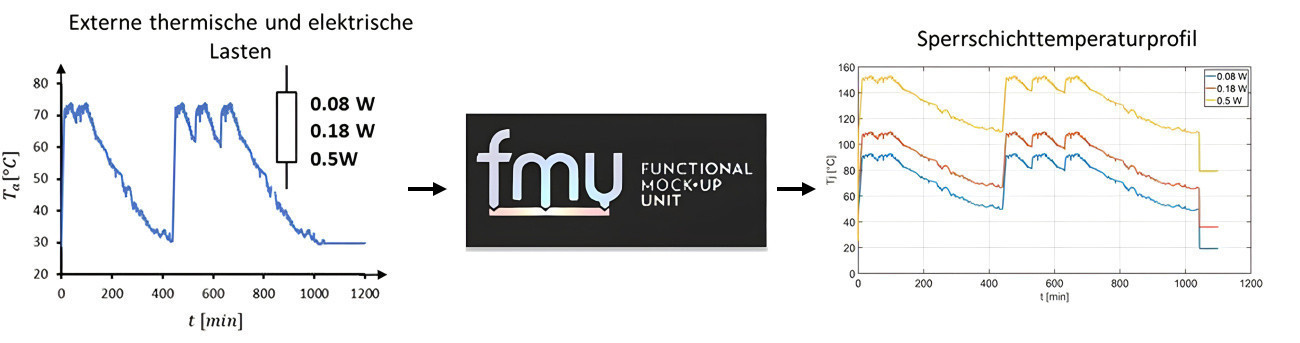

The multidomain simulation concept uses a bridge rectifier circuit for demonstration, where the junction temperature is considered as the main stressor that leads to thermal degradation of the bridge rectifier package as well as the assembly and connection technology. In this context, the behavior of the junction temperature is determined by subjecting the circuit to an operational profile that is exposed to external thermal and electrical stresses. The information from the deployment profile is then fed into the FMU model generated from Modelica in order to carry out parametric studies. In addition, the simulation is performed in Python and automated by using the Python library for simulating FMU models, FMPy(Fig. 2).

Fig. 2: Workflow of the Mission Profile-based calculation of the junction temperature profiles of the bridge rectifier

Fig. 2: Workflow of the Mission Profile-based calculation of the junction temperature profiles of the bridge rectifier

This approach aims to create a digital twin that proactively reacts to age-related changes or anomalies in the behavior of the electronic system.

In the demonstrated method applied to the example circuit, the following techniques were used:

- Derivation of the possible ambient temperature usage profiles to which the bridge rectifier may be exposed during operation for automotive applications

- Multi-domain behavioral modeling of the bridge rectifier using the FMI standard, considering the bridge rectifier as a black box

- Co-simulation of the junction temperature profile of the bridge rectifier in Python using the FMU model generated from the Modelica implementation of the electrical and thermal behavior model

- Performed automated, time-efficient and parametric studies under variation of ambient temperature but under constant electrical load in Python

Multi-domain behavioral modeling using the FMI standard has proven to be able to couple as well as simulate different physical domains, namely thermal and electrical domains, in an open source environment. The methodology was also able to perform time-efficient, automated and parametric studies while saving the results as *.csv.

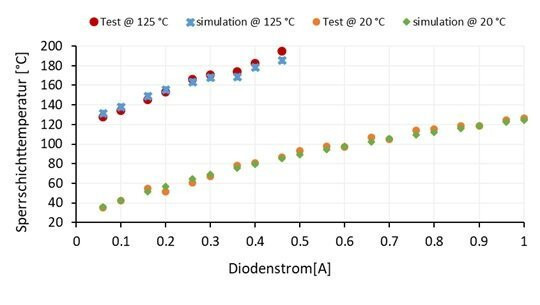

A temperature step test from -40 °C to 150 °C was performed to validate the simulated junction temperature of the bridge rectifier at varying ambient temperatures and electrical loads. The simulation results show a good correlation with the test results(Fig. 3). In addition, passive temperature cycling tests will be performed in future work to determine whether the characteristic curves of the diode can be considered as valid damage or degradation sensitive parameters.

Fig. 3: Test and simulation results of the junction temperatures of the bridge rectifier at 20 °C in the initial state

Fig. 3: Test and simulation results of the junction temperatures of the bridge rectifier at 20 °C in the initial state

Conclusion

Overall, the proposed simulation-based digital twin methodology can be adapted for various fault mechanisms of different system complexity levels. These techniques are useful for providing inputs to analytical systems that support predictive maintenance of critical subsystems, especially under abnormal operating conditions or tampering.

The presented approach can be applied to more complex systems where more than two domains need to be coupled, e.g. the thermomechanical and electrical domains, to couple different software tools or simulation models to create a complete digital twin of the physical system. Several methods are available for coupling different simulation models or software with a higher degree of complexity, especially when the system behavior needs to be described considering more than one failure mechanism or physical domains. Model order reduction or metadata modeling methods, for example, can be applied to FEM models that provide an accurate representation of how certain domains affect the degradation of different materials. These models can be exported as FMU models and imported into an object-oriented circuit simulation platform and coupled with other different domains for virtual health monitoring of system behavior during operation.

The data transfer between the models can be controlled by implementing a master-slave algorithm, resulting in an efficient, less time-consuming simulation. With higher system complexity, the data transfer between the FMU models must also be considered intensively through model exchange or co-simulation.

Literature

[1] Goedecke, A.; Muehlbauer, M.; Nieverler, J.; Vittorias, I.; Vontz, T.: FEM models in System Simulations using Model Order Reduction and Functional Mock up Interface, 9th International Modelica Conference (2012) 565-570.

[2] Kopp, M.;Hofmann, D.; Bertsche, B.; Hess, C.; Fritz, O.: Early reliability estimation in automotive industry, International conference on engineering design, (2011) 15-18.

[3] Hentze, J.; Thorben, K.; Iris, G.; Walter, S.: Integrated modeling of behavior and reliability in system development, 21st International Conference on Engineering Design, (2017).

[4] Tsui, K.L. et al: Prognostics and health management: a review on data driven approaches, Math. Problems Eng, (2015), 1-17.

[5] Dobs, T.; Elsotohy, M.; Jaeschke, J.; Sehr, F.; Strogies, J.; Wilke, K.: Multi domain system level modeling approach for assessment of degradation behavior under thermal and thermo-mechanical stress, Microelectronics Reliability, (2022).

[6] Elmqvist, H.; Matsson, S.E.; Otter, M.: Object-Oriented and Hybrid Modeling in Modelica, Journal Européen des systèmes automatisés, (2001).

[7] Daigle, M J.; Goebel, K.: Model-based prognostics with concurrent damage progression processes, IEEE Trans. Syst., Man, Cybern.: Syst. 43 (3) (2013), 535-546, https://doi.org/10.1109/TSMCA.2012.2207109.

[8] Piromalis, M.; Kantaros, A.: Digital Twins in the Automotive Industry: The Road toward Physical-Digital Convergence, (2022).

[9] Groemer M. et, al: Digital-Twin-Computational methods for the analysis and optimization of Cyber-Physical Systems, 16th. Symposium on Energy Innovation, (2020).

[10] Perabo, F. et al: Digital Twin Modeling of Ship Power and Propulsion Systems: Application of the Open Simulation Platform (OSP), 29th International Symposium on Industrial Electronics (ISIE), (2020).

[11] Wiens, M.; Meyer. T.; Thomas, P.: The Potential of FMI for the Development of Digital Twins for Large Modular Multi - Domain Systems, 14th International Modelica Conference, (2021).

[12] Negri, E.; Fumagalli, L.; Cimino, C.; Macchi, M.: FMU-supported simulation for CPS Digital Twin, International Conference on Changeable, Agile, Reconfigurable and Virtual Production, (2019).

[13] Rajesh, P.K.; Manikandan, N.; Ramshankar, C.S.; Vishwanathan, T.; Sathoshkumar, C.: Digital Twin of an Automotive Brake Pad for Predictive Maintenance, International Conference on recent Trends in advanced computing, (2019), 18-19.

[14] Pohlmann, U.; Wagner, R.: Use of the FMI/FMU standard for early simulation of software and hardware models of complex mechatronic systems, Tag des Systems Engineering, (2012).