The Liebherr-Elektronik GmbH test center in Lindau is on the trail of so-called fake components. For good reason: If these are installed unnoticed, this can mean more than just higher costs and effort. Product safety and legal compliance are also at stake.

Insights into the SMD production line at Liebherr Elektronik in Lindau Electronic components are currently a rare commodity. Even the least critical components, which were still readily available a few months ago, have now become a scarce commodity. The current component crisis is made up of many factors: very high demand, the effects of the coronavirus pandemic and other factors such as the accident in the Suez Canal or extreme weather events in production areas.

Insights into the SMD production line at Liebherr Elektronik in Lindau Electronic components are currently a rare commodity. Even the least critical components, which were still readily available a few months ago, have now become a scarce commodity. The current component crisis is made up of many factors: very high demand, the effects of the coronavirus pandemic and other factors such as the accident in the Suez Canal or extreme weather events in production areas.

Due to the current shortage of materials, numerous manufacturers of electronic components have been forced to sell their goods according to the allocation process. One of the consequences of this is that suppliers can only partially fulfill orders and delivery deadlines cannot be met.

In addition to the sharp price increases, the current supply bottlenecks pose extensive challenges for purchasing and supplier quality to ensure delivery capability. The focus is not only on the required quantity, but also on the quality of the components. Due to the material bottlenecks, Purchasing has to look for alternative procurement sources to cover the necessary requirements for many components.

Electronic components from an independent distributor

Some components have to be elaborately prepared so that their inner workings can be viewed under a microscopeIn order tobe able to continue to ensure delivery capability, electronics manufacturers rely on material purchases from independent distributors. These are suppliers who do not have franchise agreements with the component manufacturers and are not authorized by them. In the past, Liebherr-Elektronik GmbH already commissioned its authorized independent distributors when a component was discontinued and a last-time buy was not possible.

Some components have to be elaborately prepared so that their inner workings can be viewed under a microscopeIn order tobe able to continue to ensure delivery capability, electronics manufacturers rely on material purchases from independent distributors. These are suppliers who do not have franchise agreements with the component manufacturers and are not authorized by them. In the past, Liebherr-Elektronik GmbH already commissioned its authorized independent distributors when a component was discontinued and a last-time buy was not possible.

"Before the component crisis, there were a maximum of ten to twenty purchases from independent distributors per year, today there are two per day," reports Erhan Akyildirim, responsible for the supplier quality of active and passive components at Liebherr-Elektronik GmbH. "The prices are also often horrendous: some of the components we need cost up to fifty times the regular price".

Many companies have strict purchasing processes when selecting independent distributors. Akyildirim: "If we cannot purchase directly from the manufacturer or from a distributor authorized by the manufacturer, we have a small, select group of approved independent distributors at our disposal. Based on our quality assurance agreement, we oblige them to comply with high quality standards."

For example, delivery to Liebherr may only take place once the origin of the components has been verified and full traceability to the manufacturer has been confirmed with a corresponding Certificate of Conformity (CoC). It only becomes problematic if an independent distributor cannot provide proof of the originality of the goods. Then the delivery becomes so-called broker goods. Depending on the situation, Liebherr decides whether delivery can still be granted.

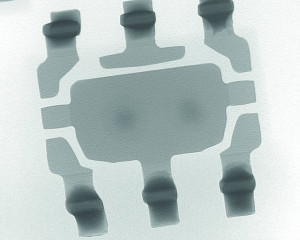

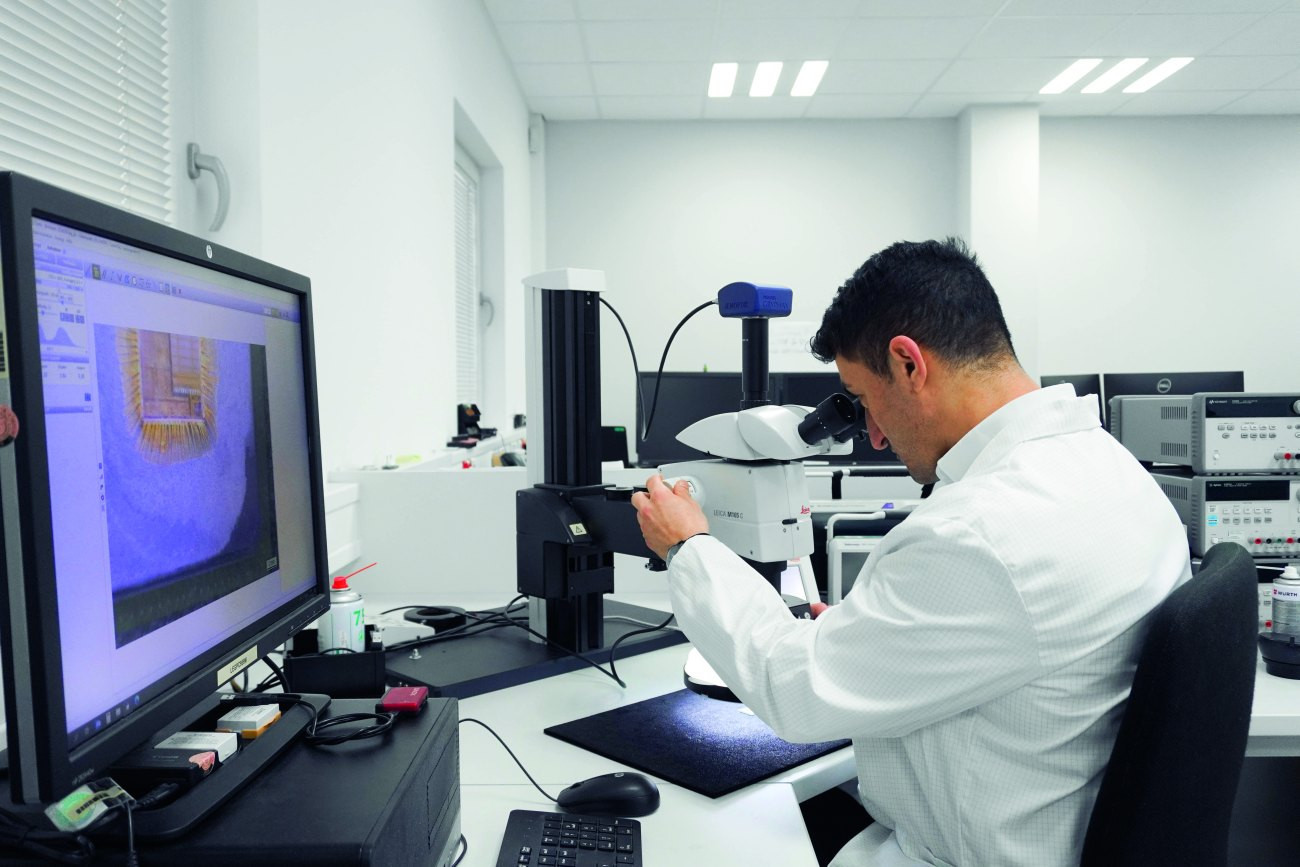

Erhan Akyildirim uses a stereo microscope to check components in detail for anomalies

Erhan Akyildirim uses a stereo microscope to check components in detail for anomalies

"These components must meet the criteria of the SAE AS6081 standard before they are delivered to us," says Jens Mulack, Head of Supplier Quality. It is no coincidence that this standard originates from the aviation sector - the production of electronics for this industry has significantly influenced supplier management and the quality processes at Liebherr-Elektronik GmbH.

Test and approval procedure according to aviation standard

Raphael Hirsch, team leader in the analysis laboratory at Liebherr-Elektronik GmbH, at the X-ray inspection systemOncethe deliveryhas beenapproved, Liebherr-Elektronik has established a comprehensive test and approval process with reference to the aviation standard SAE AS6171 as well as supplementary tests in order to ensure the reliability and quality of the component as far as possible. This includes extensive analyses in our in-house laboratory and electrical tests at an external service provider. From packaging tests and optical inspections to X-rays, the company invests a great deal of effort in in-depth material analysis.

Raphael Hirsch, team leader in the analysis laboratory at Liebherr-Elektronik GmbH, at the X-ray inspection systemOncethe deliveryhas beenapproved, Liebherr-Elektronik has established a comprehensive test and approval process with reference to the aviation standard SAE AS6171 as well as supplementary tests in order to ensure the reliability and quality of the component as far as possible. This includes extensive analyses in our in-house laboratory and electrical tests at an external service provider. From packaging tests and optical inspections to X-rays, the company invests a great deal of effort in in-depth material analysis.

"The extensive product tests are complex and time-consuming - this can delay the delivery of a final product to the customer by several days to weeks. In return, we have ensured the reliability and quality of the components as well as possible," explains Mulack.

If the component does not pass one of the tests, it is classified as suspect. Defined measures are then taken, such as notifying the supplier, initiating a complaint and destroying the components. This ensures that the suspect components cannot be put back into circulation.

The manufacturer of electronic components keeps coming across fake components. Erhan Akyildirim has already come across the most curious cases: "Some optical counterfeits are relatively easy to detect. With original components, the marking is created with a laser. Counterfeit components are often printed and this printing can sometimes be easily wiped off."

Undetected cases can have serious consequences for electronics manufacturers. "From semiconductors and capacitors to ordinary batteries - everything can be counterfeit, even if the component only has a purchase value of ten cents," says Raphael Hirsch, team leader in the analysis laboratory at Liebherr-Elektronik.

High test depth is crucial

The undetected use of counterfeit components harbors a number of risks. Under certain circumstances, this can mean more than just higher expenses and costs; product safety and legal compliance can also be at stake.

Electronic components in the area of functional safety, for example, must fulfill the probability of failure calculated in advance on the basis of component parameters. The primary objective here is to protect people and the environment. If defective parts are installed in the electronic component, this can lead to a significantly higher risk than the calculated risk.

Liebherr-Elektronik combines a wide variety of control procedures to track down fake components

Liebherr-Elektronik combines a wide variety of control procedures to track down fake components

Another example: Since combustion engines have been subject to strict emission regulations, the originality of the components used for them has also been stipulated by law to ensure that the defined emission values are complied with during operation. The use of unrecognized fake components can constitute a violation of the law.

Fake components as a security risk

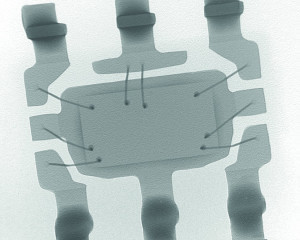

The analysis of X-ray images sometimes reveals dangerous curiosities ...But fakes are not always so obvious. When it comes to the functionality of the components, things get trickier: when testing a voltage regulator for an electronic control unit (ECU), the manufacturer had specified a permissible temperature range of -55 °C to +125 °C. "During external testing in the test house, however, the component failed the +125 °C high-temperature test," says Akyildirim. "It would have been unthinkable if this had only become apparent during use by the customer, for example during the harvesting operation of an agricultural machine." Another unusual case occurred not so long ago. Just recently, components without a chip were delivered to the electronics component manufacturer.

The analysis of X-ray images sometimes reveals dangerous curiosities ...But fakes are not always so obvious. When it comes to the functionality of the components, things get trickier: when testing a voltage regulator for an electronic control unit (ECU), the manufacturer had specified a permissible temperature range of -55 °C to +125 °C. "During external testing in the test house, however, the component failed the +125 °C high-temperature test," says Akyildirim. "It would have been unthinkable if this had only become apparent during use by the customer, for example during the harvesting operation of an agricultural machine." Another unusual case occurred not so long ago. Just recently, components without a chip were delivered to the electronics component manufacturer.

Trustworthy electronics: traceability as a success factor

Especially since the coronavirus pandemic and the associated component crisis, the term 'trusted electronics' is no longer a foreign concept in the industry. An electronic component can only be described as trustworthy if the manufacturing and supply chain can be fully traced. This requires complete traceability of the individual parts contained in the component.

Not every electronics manufacturer ensures complete traceability throughout the entire manufacturing and assembly process. This also means that if a product fails, it is not possible to determine immediately whether and which other products could be affected by the same fault if there is no traceability.

At Liebherr-Elektronik, the traceability concept is based on two pillars: clearly defined purchasing processes for quality assurance of broker goods and seamless traceability using the Manufacturing Execution System (MES). For every electronic component that is produced, the MES automatically creates a product life cycle - from the assembly of the PCB to the assembly and testing of the component through to delivery to the customer.

... it recently happened that the housing contained neither chip nor bond wires (right-hand image)

Every step is documented down to the last component level - for all installed elements. This enables the company to trace which component was assembled on which PCB and even at which position. The documentation also includes assembly and final test logs as well as delivery bills. In the event of a complaint, it is thus possible to reliably determine which component batch from which manufacturer is responsible for a functional failure. This also allows immediate measures to be derived for other components in which parts from this batch are installed - thus minimizing risks and costs. Every year, the company assembles over 200,000 PCBs with around 160 million SMD components.

Jens Mulack is not aware of any case in which counterfeit goods have been placed on the market by Liebherr-Elektronik: "Our high test coverage and traceability have so far uncovered every counterfeit. Of course, there is always a residual risk - there is no such thing as 100% in this industry."

Mulack assumes that the component crisis will continue to pose challenges for the industry in 2022: "We will have to continue to react flexibly to changes, but we are optimistic about the future."

Safeguarding in-house production and EMS

Liebherr-Elektronik GmbH is the Liebherr Group's competence center for electronics. An in-house test center at the company's Lindau site enables comprehensive material analyses, environmental tests, vibration tests and electromagnetic compatibility tests. The in-house test center is not only an advantage for series products. Comprehensive tests also ensure the reliability and quality of components for assembly services (Electronics Manufacturing Services), which the company offers.