High Power Impulse Magnetron Sputtering (HiPIMS) is being used in an increasingly wide range of applications. One major field of application, for example, is the coating of carbide precision tools.

Carbide precision tools for machining (e.g. milling or turning) are coated with physical (PVD) or chemical vapor deposition (CVD) in order to meet the high requirements. The arc and DCMS (direct current magnetron sputtering) processes have dominated the PVD sector for decades.

In recent years, the PVD process HiPIMS (High Power Impulse Magnetron Sputtering) has increasingly become the focus of the machining industry. Research has already made significant progress in this area. Since the observation of high peak currents through high-frequency pulsing by Kouznetsov in 1999 [1], researchers have published several hundred papers on the subject of HiPIMS. While the phenomena and technical details of the HiPIMS process are of great interest to researchers and developers, the focus for users and manufacturers of cutting tools is more on the use and performance of the coatings. The chain of requirements extends from basic research to the user of the cutting tools.

Lots of movement in research

A fundamental understanding of the technology plays a key role in basic research. Around a dozen research groups around the world are working exclusively on HiPIMS technology and trying to penetrate every influencing variable of the numerous parameters. Many publications provide answers to questions that developers and users from industry have not even asked themselves yet. Important insights have been gained over the years. Greczynski et al. showed that the ionized atoms of the cathode pulse move in time-dependent waves to the substrate and that a pulsed and synchronized bias can selectively pick up the desired ions [2, 3]. Anders et al. developed a model for the movement of the atoms and the back-sputtering effect observed in HiPIMS [4]. Gudmundsson et al. helped to make a clear distinction between HiPIMS and DCMS and defined an intermediate range, which they called MPP (Modulated Pulse Power) [5]. These and countless other publications helped to understand HiPIMS technology and make it more usable.

Economical coating production in the industry

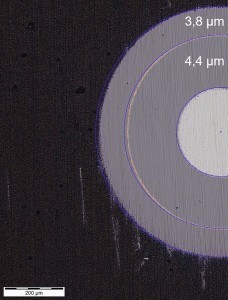

Fig. 1: Cross section of an AlTiN double layer coating. The first layer is deposited using HiPIMS (4.4 µm). The second layer was deposited using DC magnetron sputtering (3.8 µm). The two layers were deposited in one batch with the same targets and a coating time of two hours each. For the development departments in industry, this is where the link to basic research lies: applying the appropriate findings from the countless publications to current development issues. While basic research deals with HiPIMS coatings made from a wide variety of materials, only those that have a wear-reducing effect in machining are relevant for developers in the machining industry. The use of HiPIMS technology in no way reduces the horizon here, as many well-known material groups, such as common aluminum titanium nitride or aluminum chromium nitride, can be easily transferred from common sputtering or arc technology. However, the hardware is important in order to gain access to HiPIMS technology, as unlike some researchers, most development departments do not have the capacity or knowledge to set up their own equipment. The high cost is mainly due to the interaction of power and gas supply, heating, pumping station and cathode design with the system control, which must ensure maximum flexibility and reproducibility of coating recipes for industrial applications. Major system manufacturers such as Oerlikon Balzers, CemeCon, IHI Hauzer and Kobelco are therefore already relying on so-called "turn-key" solutions for industrial customers in order to facilitate easy access to the technology. However, for developers to be able to convince within their organization, economic efficiency in production must be ensured. The low deposition rates of HiPIMS, which are often reported in publications, are a major issue here. The system manufacturers mentioned have therefore also set themselves the goal of achieving at least the deposition rates of conventional sputtering technology. Depending on the parameter set, however, deposition rates of more than 2 µm/h can also be achieved, as a test with aluminum titanium nitride in Figure 1 shows.

Fig. 1: Cross section of an AlTiN double layer coating. The first layer is deposited using HiPIMS (4.4 µm). The second layer was deposited using DC magnetron sputtering (3.8 µm). The two layers were deposited in one batch with the same targets and a coating time of two hours each. For the development departments in industry, this is where the link to basic research lies: applying the appropriate findings from the countless publications to current development issues. While basic research deals with HiPIMS coatings made from a wide variety of materials, only those that have a wear-reducing effect in machining are relevant for developers in the machining industry. The use of HiPIMS technology in no way reduces the horizon here, as many well-known material groups, such as common aluminum titanium nitride or aluminum chromium nitride, can be easily transferred from common sputtering or arc technology. However, the hardware is important in order to gain access to HiPIMS technology, as unlike some researchers, most development departments do not have the capacity or knowledge to set up their own equipment. The high cost is mainly due to the interaction of power and gas supply, heating, pumping station and cathode design with the system control, which must ensure maximum flexibility and reproducibility of coating recipes for industrial applications. Major system manufacturers such as Oerlikon Balzers, CemeCon, IHI Hauzer and Kobelco are therefore already relying on so-called "turn-key" solutions for industrial customers in order to facilitate easy access to the technology. However, for developers to be able to convince within their organization, economic efficiency in production must be ensured. The low deposition rates of HiPIMS, which are often reported in publications, are a major issue here. The system manufacturers mentioned have therefore also set themselves the goal of achieving at least the deposition rates of conventional sputtering technology. Depending on the parameter set, however, deposition rates of more than 2 µm/h can also be achieved, as a test with aluminum titanium nitride in Figure 1 shows.

Since the machining industry, unlike the glass industry for example, primarily relies on batch production, the volume per batch is a decisive factor for producers' calculations. Here, too, there are already industrial solutions that can handle inserts in the low five-digit range per batch and 4-5 batches per day. This puts HiPIMS between arc and conventional DC magnetron sputter technologies in terms of cost-effectiveness.

Increased performance for users

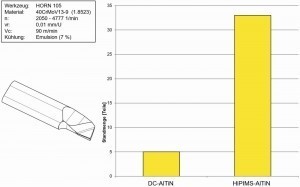

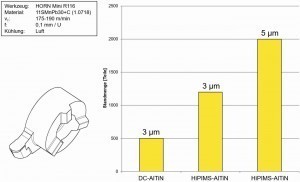

At the end of the requirements chain are the users, who use cutting tools and rely on the performance taking a further leap. Available test results show that leaps of several hundred percent in the service life of the tools are possible. Examples can be seen in Figures 2 and 3.

This means that the customer also benefits significantly from the use of HiPIMS technology.

Summary

HiPIMS technology has penetrated all areas from research to developers and producers in industry to users - with success. The economical production of highly wear-resistant coatings for cutting tools and the long tool life are proof of this.

INFO

The Paul Horn GmbH

In 70 countries on all continents, companies in the automotive, chemical, aerospace, medical technology and tool and mold making industries produce with tools from Paul Horn GmbH. In addition to 25,000 standard tools, the family-run company has delivered over 150,000 special solutions to its customers to date. Founded in 1969 in Gomaringen in the Tübingen region, the carbide tool manufacturer is now an important producer of precision tools for demanding machining tasks. Horn produces at the company headquarters in Tübingen as well as in England, Italy, the Czech Republic and the USA. In 2019, the sales volume in Germany amounted to 196 million euros and around 300 million euros worldwide. The company has 1,000 employees in Germany and 1,500 worldwide. Paul Horn is the largest industrial employer in Tübingen and offers 75 apprenticeships.

INFO

IFKB University of Stuttgart

The Institute for Manufacturing Technology of Ceramic Components (IFKB) at the University of Stuttgart, headed by Professor Rainer Gadow since 1995, combines modern material systems from the fields of high-performance ceramics, composite materials and surface technology. The focus is on the development of structural and functional components as well as high-performance surfaces and lightweight construction solutions for applications in automotive, aerospace, medical technology, mechanical and plant engineering as well as energy and power plant technology. The institute is divided into four research areas: Composites, High-Performance Ceramics, Surface Technology and Coated Composites, Simulation and Mechanics of Materials.

www.ifkb.uni-stuttgart.de

THE AUTHORS

Bastian Gaedike studied materials science and materials and production engineering at the University of Stuttgart. He now works as a coating developer at Hartmetall-Werkzeugfabrik Paul Horn GmbH

Prof. Rainer Gadow teaches at the University of Stuttgart and is head of the Institute for Manufacturing Technology of Ceramic Components (IFKB) at the University of Stuttgart

Literature

[1] Kouznetsov, V.; Macák, K.; Schneider, J.M.; Helmersson, U.; Petrov, I.: A novel pulsed magnetron sputter technique utilizing very high target power densities, Surface and Coatings Technology 1999, 122, 290-293

[2] Greczynski, G.; Lu, J.; Jensen, J.; Petrov, I., Greene, J.E.; Bolz, S.; Koelker, W.; Schiffers, C.; Lemmer, O.; Hultman, L.: Metal versus rare-gas ion irradiation during Ti1-xAlxN film growth by hybrid high power pulse magnetron/dc mag-netron co-sputtering using synchronized pulsed substrate bias, Journal of Vacuum Science & Technology A 2012, 30, 061504

[3] Greczynski, G.; Lu, J.; Jensen, J.; Petrov, I.; Greene, J.E.; Bolz, S.; Kölker, W.; Schiffers, Ch.; Lemmer, O.; Hultman, L.: Strain-free, single-phase metastable Ti0.38Al0.62N alloys with high hardness: metal-ion energy vs. momentum effects during film growth by hybrid high-power pulsed/dc magnetron cosputtering, Thin Solid Films 2014, 556, 87-98

[4] Anders, A.; Čapek, J.; Hála, M.; Martinu, L.: The 'recycling trap': a generalized explanation of discharge runaway in high-power impulse magnetron sputtering, Journal of Physics D: Applied Physics 2012, 45, 012003

[5] Gudmundsson, J.T.; Brenning, N.; Lundin, Helmersson, U.: High power impulse magnetron sputtering discharge, Journal of Vacuum Science & Technology A: Vacuum, Surfaces and Films 2012, 30, 03081