The advantage of decontaminating wood surfaces contaminated with organochlorine biocides using plasma lies in the avoidance of the use of solvents, a completely dry process and the avoidance of mechanical damage.

1 Introduction

Fig. 1: Photograph of the APPJ "T-Spot "In this context, the main objective of the investigations carried out here was to develop a process for the degradation of organochlorine preservatives from wood surfaces using atmospheric pressure plasma. A plasma jet was used for depletion and this was guided in a meandering pattern over the contaminated wood surfaces. Temperature measurements were carried out to characterize the treatment effect and the Cl content was determined using X-ray fluorescence analysis. The investigations showed that it is generally possible to remove wood preservatives from the wood surface using this process, but that a certain material temperature should be reached in order to be effective. By selecting suitable process parameters, decontamination levels on the surface of more than 90 % were possible.

Fig. 1: Photograph of the APPJ "T-Spot "In this context, the main objective of the investigations carried out here was to develop a process for the degradation of organochlorine preservatives from wood surfaces using atmospheric pressure plasma. A plasma jet was used for depletion and this was guided in a meandering pattern over the contaminated wood surfaces. Temperature measurements were carried out to characterize the treatment effect and the Cl content was determined using X-ray fluorescence analysis. The investigations showed that it is generally possible to remove wood preservatives from the wood surface using this process, but that a certain material temperature should be reached in order to be effective. By selecting suitable process parameters, decontamination levels on the surface of more than 90 % were possible.

For decades, organochlorine biocides such as DDT (dichlorodiphenyltrichloroethane), lindane and PCP (pentachlorophenol) were used worldwide in very high quantities for insect and fungal control as well as preventive material (wood, textiles, leather) and plant protection. In the FRG and the GDR, combinations of DDT and lindane, PCP and lindane and PCP and DDT were mainly used as wood preservatives. Both the production and commercial use of these active substances were discontinued in Germany at the end of the 1980s. However, studies on contaminated wood have shown that the biocides are still present in treated wood, sometimes at very high levels. The problem here is that DDT and PCP tend to migrate from the interior of the wood to the surface, where they are present in crystalline form and bound to dust. This can lead to aesthetic disadvantages, but also to health risks through contact with indoor air [1]. There is often a need for action or remediation due to excessive levels of wood preservative in the indoor air.

In principle, existing decontamination options are

- Removal and disposal of the contaminated wood

- Removal of biocides from the wood or wood surfaces

- Fixing/sealing the biocides in the wood and preventing their release.

Wood in building structures can be cleaned and sealed with special paints, thus masking the biocides. The same can also be achieved by sealing with films. However, these options are undesirable in many cases, as the wood should be visible in living and working spaces [2].

The simplest and most commonly used mechanical methods involve removing crystalline efflorescence, dust-like deposits and vacuum cleaning. This also includes blasting and dry ice blasting processes. However, this can easily lead to partial carry-over on the surfaces and incorporation of biocides into the wood structure. In addition, due to the release of dust, sufficient occupational health and safety protection is required for the people carrying out the work [3]. Other frequently used methods for the decontamination of wood surfaces are the vacuum washing method (non-abrasive, usually active substance removal of 50-70% from a depth of a few millimeters [4, 5]), thermal methods (removal of volatile biocides by heated air or microwaves, rather limited to highly volatile biocides [2]) or laser ablation (targeted laser absorption of dark dust particles, removal of the contamination layer close to the surface [6]).

Plasma systems, more precisely atmospheric pressure plasma jets (APPJ), were used for the decontamination of biocide-contaminated wood. The plasma-chemical oxidation of hydrocarbons with the formation of volatile reaction products (e.g. CO, HCHO) is already effective under ambient conditions, whereby alkenes and aromatics are most easily destroyed [7]. Due to the high-energy content and high-energy UV radiation of plasmas, all chemical bonds are destroyed, including C-Cl and C-F bonds [8, 9]. The APPJs used in our own work also have a thermal effect, which will also be described and discussed in this publication.

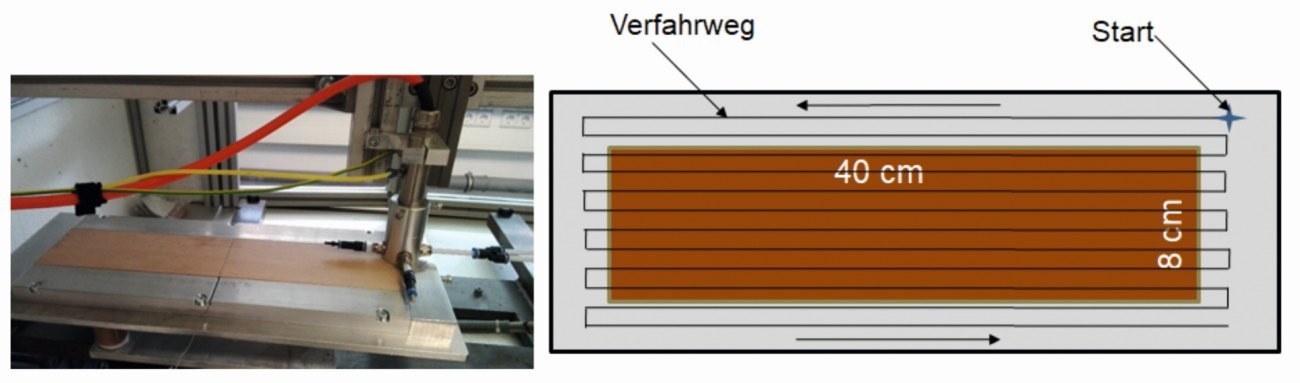

Fig. 2: Photograph of the APPJ "T-Spot" and sample table with wooden substrate (left); schematic representation of the meandering movement (black line) of the sample table during plasma treatment, brown area symbolizes the position of the wooden test specimen

Fig. 2: Photograph of the APPJ "T-Spot" and sample table with wooden substrate (left); schematic representation of the meandering movement (black line) of the sample table during plasma treatment, brown area symbolizes the position of the wooden test specimen

2 Material and methods

Beech was used as the model wood for decontamination. Beech can be impregnated to a sufficient depth and homogeneously and does not contain any interfering wood constituents. Beech scantlings with the dimensions 400 × 80 × 20 mm3 were used in the tests.

DDT and PCP were applied to the model test specimens as an isopropanolic solution using a spatula. Quantities of 1000 mg DDT/kg wood and 1500 mg PCP/kg wood were used. The mass of the wood was related to the first 3 mm of the respective scantling.

The "T-Spot" APPJ system from Tigres GmbH was used for decontamination. An illustration of the APPJ is shown in Figure 1. In the device, an electrical discharge takes place between a centrally arranged high-power ceramic electrode and the nozzle serving as a counter electrode. The adjustable power range is between 230-500 W; 230 W and 400 W were used for the tests presented here. In the laboratory, the wood surface was meandered for decontamination with the plasma, whereby the material was moved relative to the outlet opening of the plasma by means of an x-y positioning system. A schematic representation of the path of travel can be found in Figure 2. In addition, the plasma jet was encased in an aluminum cylinder through which any degradation products or gaseous wood preservatives could be extracted.

The following table (Table 1) provides an overview of the process parameters used.

| Parameters | Setting range |

| Power | 230, 400 W |

| Substrate speed | 50-500 mm/s |

| Number of treatment cycles | 1-10 |

| Distance plasma to substrate | 10 mm |

| Wood preservative | PCP, DDT |

A pronounced temperature dependency is to be expected in the decontamination of the wood surface from PCP and DDT. In order to correlate treatment effects (wood preservative depletion) with the surface temperature reached, corresponding temperature measurements were carried out during the plasma treatment. The temperature measurements during the T-spot treatment were carried out using a K-type thermocouple directly on and 1 mm below the wood surface. For this purpose, holes were drilled into the long side of the test specimen and the wire of the thermocouple was placed there.

The decontamination effect was determined using mobile X-ray fluorescence analysis (XRF). The intensity of the Cl signal was used as the basis for evaluating the decontamination.

3 Results and discussion

3.1 Temperature measurements

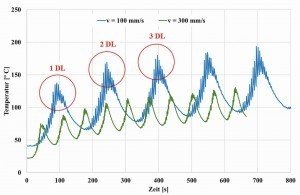

In any case, the formation of undesirable discoloration or other damage to the wood surfaces must be avoided, which was possible by selecting suitable process parameters. During the treatment, the temperature-time profiles shown as an example in Figure 3 were recorded using a K-type thermocouple.

|

Travel speed [mm/s] |

Number of passes |

Tmax [°C] Surface |

Tmax [°C] 1 mm below surface |

Total treatment time [s] | Cl-reduction [%] |

| 300 | 2 | 75 | 40 | 140 | 21 |

| 300 | 4 | 85 | 50 | 280 | 35 |

| 300 | 10 | 130 | 60 | 700 | 73 |

| 100 | 1 | 130 | 80 | 165 | 80 |

| 100 | 2 | 170 | 95 | 345 | 95 |

| 100 | 3 | 180 | 100 | 510 | 98 |

As an example, this figure shows the temperature curve directly on the wood surface at a plasma power of 400 W. In addition, the areas circled in red highlight the maximum temperature of the respective treatment cycle (DL). The diagram also compares two different travel speeds of 100 mm/s and 300 mm/s, whereby significantly higher temperatures are achieved at the slower speeds (v = 100 mm/s, 1 pass: Tmax = 130 °C) than at fast speeds (v = 300 mm/s, 1 pass: Tmax = 70 °C). It should be mentioned here that this is an extremely short-term temperature exposure and does not cause any optical damage to the material. For further evaluation, the maximum temperatures reached in each run were considered.

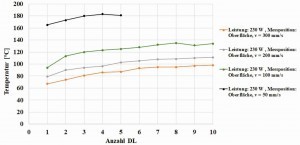

Figure 4 shows the dependence of the temperature on the substrate speed at a plasma power of 230 W. As the substrate speed increases, the maximum surface temperature decreases. The choice of low substrate speeds (e.g. 50 mm/s) may well result in damage to the material by reaching excessively high temperatures.

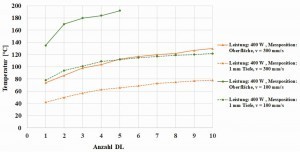

Figure 5 also shows the dependence of the temperature reached on the measuring point (proximity to the treated surface). It is clear that the temperatures directly on the surface are significantly higher than the temperatures below (1 mm) the substrate surface. With a strongly temperature-dependent process, it can therefore be assumed that the decontamination effect will be strongest in the upper wood areas. Overall, the choice of substrate speed, the number of treatment runs, but also the plasma power offered the most effective way of regulating the substrate temperature.

3.2 Decontamination

Fig. 5: Maximum temperature (Tmax) as a function of the number of treatment runs (DL) for substrate speeds of 100 mm/s and 300 mm/s, variation of the measurement position in the material: directly on or 1 mm below the surfaceThe aimof the investigations was to determine the Cl degradation rate as a function of various plasma process parameters. In particular, the influence of the traversing/table speed and the number of treatment runs were examined. Both process parameters also influence the surface temperature during treatment. The plasma power was kept constant at a value of 400 W. The decontamination effect was analyzed by XRF, using the intensity of the Cl signal as the basis for evaluating this effect. A reduction in the intensity of this Cl signal describes a degradation of chlorinated wood preservatives. A selection of the results is shown in Table 2.

Fig. 5: Maximum temperature (Tmax) as a function of the number of treatment runs (DL) for substrate speeds of 100 mm/s and 300 mm/s, variation of the measurement position in the material: directly on or 1 mm below the surfaceThe aimof the investigations was to determine the Cl degradation rate as a function of various plasma process parameters. In particular, the influence of the traversing/table speed and the number of treatment runs were examined. Both process parameters also influence the surface temperature during treatment. The plasma power was kept constant at a value of 400 W. The decontamination effect was analyzed by XRF, using the intensity of the Cl signal as the basis for evaluating this effect. A reduction in the intensity of this Cl signal describes a degradation of chlorinated wood preservatives. A selection of the results is shown in Table 2.

Initially, high treatment speeds of 300 mm/s were selected. If 2 DL are applied, only a small treatment effect can be determined (Cl degradation approx. 21 %). Even when the number of DL was increased to 4, Cl degradation was not very pronounced (approx. 35 %). If 10 consecutive DL are used, a clear treatment effect and a Cl reduction of approx. 73 % is shown. However, 10 DL with a total treatment time of approx. 10 min on the surface under consideration appears to be very long and impractical for one application.

If the travel speed of the substrate is reduced to 100 mm/s, a significant Cl reduction of around 80 % can be achieved after just 1 DL. If 2 DL are used, there is a further increase and a Cl reduction of 93 %.

The treatment time between the parameters 2 DL at 300 mm/s (140 s) and 1 DL 100 mm/s (165 s) are roughly comparable, but a significantly different Cl reduction is achieved. Thus, the treatment time or the plasma/wood interaction time is not the sole influencing factor. Rather, the temperature of the surface and deeper wood regions during plasma treatment appears to be a decisive influencing factor. For example, only 85 °C was measured on the surface with 2 DL at 300 mm/s, whereas 1 DL at 100 mm/s generated temperatures of up to 130 °C. A clear effect could only be determined after 10 successive DL with a traversing speed of 300 mm/s, whereby this regime led to surface temperatures of 130 °C. In addition, at 100 mm/s 1 mm below the surface, temperatures of approx. 80 °C are already reached after 1 DL, whereas in the 300 mm/s regime 80 °C are only reached after 10 DL.

The effects of the plasma treatment and the dependence on the travel speed can in principle be transferred to the PCP-loaded wood. In contrast to DDT, however, a clear Cl degradation (approx. 81 %) was observed after only 4 DL at 300 mm/s and thus at lower temperatures. One reason for this effect could be the different vapor pressures between DDT and PCP. The vapor pressure of DDT is 0.025 mPa (20 °C) [10] and the vapor pressure of PCP is significantly higher at 8 mPa (20 °C) [11]. PCP is correspondingly easier to convert to the vapor phase when exposed to temperature.

In order to achieve a high Cl degradation with a short/application-oriented treatment time (high degradation rate), a high surface temperature should already be reached in the 1 DL. This was only achieved in the tests by using a travel speed of 100 mm/s. However, it should be noted that the Cl values measured on the wood surfaces can vary greatly. The absolute values for Cl degradation should therefore be understood as a trend (Tab. 3).

|

Processing speed [mm/s] |

Number of passes |

Tmax [°C] Surface |

Tmax [°C] 1 mm below surface |

Total treatment time [s] | Cl-reduction [%] |

| 300 | 2 | 80 | 40 | 140 | 48 |

| 300 | 4 | 100 | 50 | 280 | 81 |

| 100 | 1 | 130 | 80 | 165 | 85 |

| 100 | 2 | 170 | 95 | 345 | 92 |

4 Summary and outlook

The investigations presented here have shown that it is generally possible to reduce the wood preservative load on beech model test specimens by means of APPJ treatment. Beech scantlings were deliberately contaminated with the organochlorine biocides DDT and PCP to produce the test specimens.

A pronounced temperature dependency was to be expected when decontaminating the wood surface from PCP and DDT using plasma. Temperature curves were therefore recorded during the treatment. It was found that the plasma power, the processing speed and the number of treatment cycles in particular influence the material temperatures. This makes the aforementioned process parameters important factors for the desired decontamination. Furthermore, it could be observed that the temperature input primarily takes place in the uppermost millimeters of the material; the core temperature was only slightly influenced by the plasma treatment.

The depletion of the wood preservative and the reduction of the Cl signal as a result of plasma treatment could be detected using mobile X-ray fluorescence analysis. As suspected, there was a strong dependence on temperature, so that only a small decontamination effect could be achieved if the surface temperatures were too low. If, on the other hand, parameters resulting in higher surface temperatures were selected, a decontamination level of more than 90 % could be achieved even in a short time. A temperature dependency is also reflected in the wood preservatives used. In the tests, PCP was already easier to remove from the wood at lower temperatures than DDT, which is possibly due to the significantly higher vapor pressure of PCP.

In further investigations, the gaseous wood preservative degradation products produced during the treatment process will be recorded and analyzed in order to gain a more detailed understanding of the mechanistic mode of action of the decontamination process using plasma. Furthermore, future tests on real, installed objects are planned. In addition, the effect of sealing following the decontamination process is to be tested.

Acknowledgements

Part of the work presented here was funded by the BMWi as IGF project no. 20309BR.

THE AUTHORS

Dr. Ing. Sven Gerullis

studied materials engineering at the Ernst Abbe University of Applied Sciences in Jena. He completed his doctorate in the field of atmospheric pressure plasma treatment and coating of wood surfaces. He has been a research assistant at INNOVENT e.V. since 2016 and head of the Surface Technology research department since the end of 2020.

INNOVENT e.V., Jena

Dr. rer. nat. Martin Fischer

studied chemistry and food chemistry at the Technical University of Dresden. He obtained his doctorate in the field of cellulose chemistry. He initially worked at the University of Natural Resources and Life Sciences (BOKU) in Vienna. Fischer has been a research associate at the Institute of Wood Technology Dresden gGmbH (IHD) since 2005. He works in the fields of wood chemistry, wood treatment, wood impregnation, minimization of VOC emissions and wood preservatives.

Institute for Wood Technology Dresden Dresden

Literature

[1] Aehlig, K.; Fischer. M.: Current status and problems in the assessment of contamination with the wood preservative active ingredients PCP, DDT and lindane as well as new possibilities for decontamination/minimization of the emission potential, Holzschutztagung Leipzig, 2010

[2] Unger, A.: Decontamination and Deconsolidation of Historical Wood Preservatives, Journal of Cultural Heritage, 13S, 2012, 196-202

[3] Krebs, T.; Lang, L.: Safe handling of contaminated collection items, in: Zalewski, 2014, 216

[4] Winkler, k.; Föckel, A.; Unger, A.: The vacuum washing process - decontamination of contaminated wood in the installed state, Restauro, 108, 5, 2002, 339-343

[5] Wörle, M. et al.: Evaluation of decontamination methods of pesticide contaminated wooden objects in museum collections: efficiency of the treatments and influence of the wooden structure, Journal of Cultural Heritage, 13, 2012, 209-215

[6] Jelen, E.; Widemann, G.; Püschner, K.: Decontamination of biocide loaded wooden art treasures, Poster abstract, 6th International Congress on Lasers in the Conservation of Artworks, Vienna, September 21-25, 2005, Book of Abstracts, Poster P64

[7] Trompeter F.-J.: Barrier discharges for the degradation of pollutants in engine combustion exhaust gases, Dissertation, 2001

[8] Francke, K.P.; Miessner, H.; Rudolph, R.: Plasmacatalytic processes for environmental problems, Catalysis Today, 59, 2000, 411-416

[9] Wang, T.C. et al.: Evaluation of the Potential of Pentachlorophenol Degradation in Soil by Pulsed Corona Discharge Plasma from Soil Characteristics, Environ. Sci. Technol., 44, 8, 2010, 3105-3110

[10] Dichlorodiphenyltrichloroethane, in: https://www.chemie.de/lexikon/DDT.html, Retrieved: 08.01.2021

[11] Pentachlorophenol, in: https://de.wikipedia.org/wiki/Pentachlorphenol, Retrieved: 08.01.2021