Adhesive bonds have advantages, but must also fulfill many application-specific requirements: the components must fit chemically and the bond must also be economical.

Adhesive bonds are very important in industrial production. Adhesive bonding makes it possible to join a wide variety of materials over a large area without affecting their properties in the joining zone. The materials are neither heated to high temperatures, as is the case with welding, nor weakened by drilling holes, as is the case with screw connections. Lightweight constructions and many composite materials cannot be realized without the use of adhesives. In addition to the task of joining materials, many adhesives also fulfill additional functions such as sealing, insulation or damping. The application of adhesives can be easily integrated into fully automated production processes for large quantities, so that bonding is often the most economical method of joining materials.

The formulation that is suitable for the materials to be bonded and the prevailing conditions during the application of the bonded product must be selected from a large number of adhesives available on the market. In addition to the chemical compatibility of the materials with each other and compliance with hygiene requirements, for example in the case of food contact, this also includes ensuring the necessary adhesive strength of the bonded joint. The LUMiFrac analytical centrifuge, in which up to 8 samples can be tested simultaneously, is a faster and more reliable alternative to the tensile test according to DIN EN 15870, in which only one sample at a time is clamped in a tensile testing machine. This innovative technology has now been successfully tested on a large number of material composites. The procedures and results of various studies with hot melt adhesives are described below, as well as an example of determining the strength of metallic layer systems on plastic substrates.

Test method

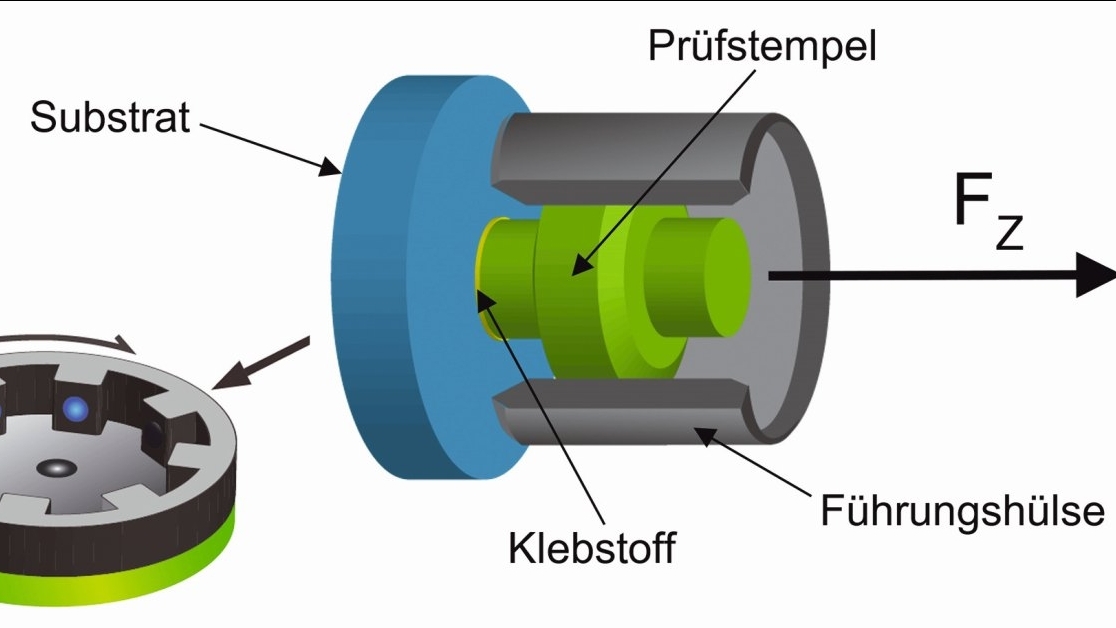

Fig. 2: Rotor of the LUMiFrac centrifuge with holders for up to eight test specimensInthe analytical centrifuge, the tensile force required to determine the adhesive strength is generated as a centrifugal force. A test specimen (Fig. 1) consisting of a substrate and a test plunger, which are connected to each other by adhesive, is inserted into the centrifuge holder provided for this purpose (Fig. 2) so that the centrifugal force acting during rotation acts in the direction of the axis of symmetry of the test plunger. A guide sleeve ensures that a pure tensile stress acts on the test specimen. A shearing effect, which would falsify the measurement result, cannot occur. During the simultaneous testing of up to 8 different test specimens, the centrifugal force is increased by increasing the speed. As soon as the load limit of the material composite of a test specimen is reached, breakage occurs and the test punch moves outwards due to the centrifugal force inside the guide sleeve. This event is detected separately for each of the 8 test specimens and transmitted by means of a position-coded infrared signal. The time of material failure of each individual test specimen and the associated rotational speeds are recorded.

Fig. 2: Rotor of the LUMiFrac centrifuge with holders for up to eight test specimensInthe analytical centrifuge, the tensile force required to determine the adhesive strength is generated as a centrifugal force. A test specimen (Fig. 1) consisting of a substrate and a test plunger, which are connected to each other by adhesive, is inserted into the centrifuge holder provided for this purpose (Fig. 2) so that the centrifugal force acting during rotation acts in the direction of the axis of symmetry of the test plunger. A guide sleeve ensures that a pure tensile stress acts on the test specimen. A shearing effect, which would falsify the measurement result, cannot occur. During the simultaneous testing of up to 8 different test specimens, the centrifugal force is increased by increasing the speed. As soon as the load limit of the material composite of a test specimen is reached, breakage occurs and the test punch moves outwards due to the centrifugal force inside the guide sleeve. This event is detected separately for each of the 8 test specimens and transmitted by means of a position-coded infrared signal. The time of material failure of each individual test specimen and the associated rotational speeds are recorded.

Using the SEPView software, the breaking force and the associated tensile stress are automatically calculated from the mass of the test punch, the distance to the center of rotation and the rotational speed at the time of material failure, displayed on the screen and saved.

Formulas for calculating centrifugal force and strength:

Fz = m ω2 r Fz - centrifugal force in N

σ = Fz/ A σ - Tensile strength in MPa (N/mm2)

m - mass in kg

r - distance to the axis of rotation in m

ω - angular velocity in 1/s

A - Adhesive surface in mm2

With a selection of different test stamps with masses between 4.1 and 38.7 g (in W/Cu version also up to 58 g) and a rotor speed of 100-13,000 rpm, tensile forces between 0.1 N and 6.5 kN are generated. Depending on the choice of bonding surface (7 or 10 mm diameter as standard, other sizes are available as special designs), tensile strengths of up to 80 MPa can be determined. The device conforms to the standards ISO 4624, JISK 5600-5-7, DIN EN 15870 and DIN EN 14869-2 and is described in DIN EN 13144 as a testing device.

The fact that the individual test specimens are only inserted and not clamped, and the possibility of analyzing up to 8 test specimens simultaneously in the centrifuge, results in a time saving of up to 85 % compared to the use of the classic tensile testing machine.

Possible applications for determining the adhesion strength of coating systems

The adhesion of coatings to different substrate materials is of fundamental importance for the functionality of products. Due to the wide variety of coating and substrate systems in terms of materials, coating thickness ranges and areas of application, there are more than 100 test methods for determining the adhesion of coatings to surfaces. Many of these methods evaluate adhesion purely qualitatively, such as the cross-cut test, in which the assessment is based on the number or area percentage of delaminated squares.

The only standardized and frequently used quantitative method that refers to the adhesive strength in terms of force per area, i.e. in N/mm2, is the peel test (ISO 4624, DIN EN 13144). Before the test, a test stamp is glued to the top layer of the sample. After the adhesive has hardened, the test stamp is removed from the sample and the force required is recorded. The test stamp and sample are then subjected to a visual inspection to determine the fracture behavior. The aim is to determine in which plane the fracture has occurred.

Provided that the adhesive strength of the test stamp on the coating is greater than the adhesive strength of the coating on the substrate, the strength of the coating to the substrate can be measured directly. If the failure occurs within the adhesive or at the layer-adhesive interface, the bond strength of the coating to the substrate is greater than the measured strength. This can be useful information for some applications. In measuring practice, mixed fractures often occur, i.e. different fracture planes are present in a sample.

The use of the analytical centrifuge as a testing device is advantageous for many coated sample systems, as the sample and test punch do not have to be clamped. The design of the test specimens and the centrifugal force, which is always directed radially, prevent the occurrence of unwanted shear forces.

Application on various materials and adhesives

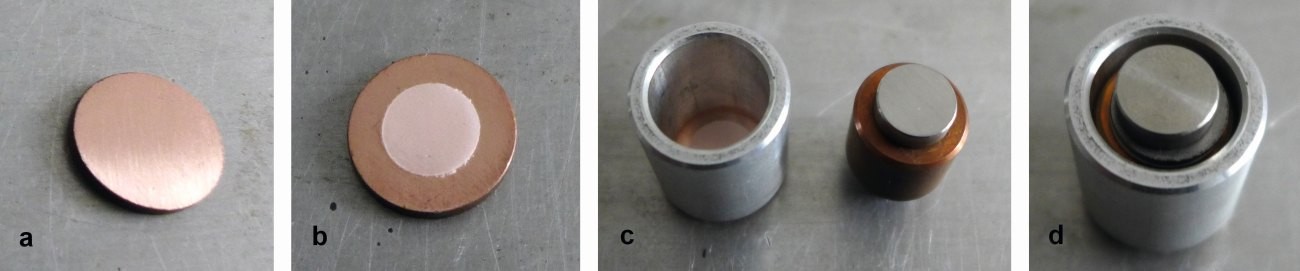

In principle, the production of test specimens is very simple: A defined amount of adhesive is applied to the adhesive surface of the test stamp, then the guide sleeve is placed on the substrate, the test stamp is inserted and guided to the substrate (see Fig. 3). However, due to the large number of adhesives and their different properties, there are also a variety of procedures for applying adhesives in practical applications. In addition, the required curing times and temperatures must be taken into account. These material-specific procedures must be taken into account when preparing the material and manufacturing the test specimens.

Fig. 3: Production of a test specimen (d), in which the adhesive is applied to the substrate (a) (b), then the guide sleeve is placed (c, left) and then the test stamp (c, right) is inserted (source: Study B, the adhesive is present here as a solid platelet about 0.2 mm thick, the material bond is created by thermal treatment)

Fig. 3: Production of a test specimen (d), in which the adhesive is applied to the substrate (a) (b), then the guide sleeve is placed (c, left) and then the test stamp (c, right) is inserted (source: Study B, the adhesive is present here as a solid platelet about 0.2 mm thick, the material bond is created by thermal treatment)

In three different studies, various adhesives, which with two exceptions must be processed at elevated temperatures, were tested with different materials. The individual tests are listed in Table 1. The letters A, B and C stand for different series of tests with formulations from different manufacturers. Each of these tests was carried out several times.

|

Study |

Adhesive |

Processing temperature in °C |

Substrate materials/test stamps |

|

A |

A-1 |

23 |

Substrate Al, stamp Al |

|

A-2 |

|||

|

A-3 |

150 |

||

|

A-4 |

|||

|

A-5 |

|||

|

B |

M7 |

180 |

Substrate Cu, punch stainless steel |

|

OP1266 |

|||

|

C |

AMS (resin) |

220 |

Substrate: Al, Cu, Zn, various plastics, stamp Al |

|

AMS Phenol (resin) |

|||

|

resin ester |

|||

|

hydrogenated resin |

|||

|

Terpene phenolic resin |

The pre-treatment of the materials, the application method for the adhesives and the post-treatment of the test specimens are shown in Table 2.

|

Study |

Pre-treatment of substrate and test stamp |

Type of adhesive application |

Post-treatment of test specimens |

|

A |

Sanding of the aluminum surfaces with P180 sandpaper, cleaning with acetone |

Applied with pipette, hot melt adhesive was heated to 150 °C and melted before application |

Processing temp. 150 °C; heating of the complete test specimen for 30 min, all: 48 h curing at room temperature |

|

B |

Sanding the surfaces of the substrate (Cu) and stamp (stainless steel) with K600 sandpaper, cleaning with acetone |

Insert a solid adhesive plate between substrate and test stamp |

Heating the complete test specimen to 180 °C for 30 min, slow cooling, curing at room temperature in 18 h |

|

C |

Degreasing of the metallic test specimens and the test stamp, rinsing with solvent and preheating to 60 °C; plastic test specimens were degreased with solvent and rinsed with alcohol |

Modified hot glue gun (for small adhesive volumes) |

Cooling to 20 °C, curing for 6 h |

Examples of test results

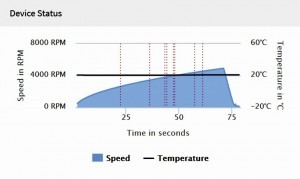

The tests listed under A and B were used to validate adhesives for a specific combination of materials. Figure 4 shows the progression of the speed over time for a measurement from study A. The vertical lines in the diagram indicate the times of material failure of the individual samples.

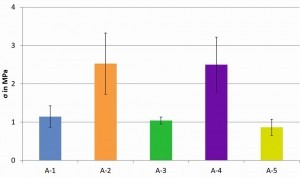

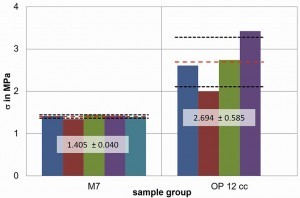

Figures 5 and 6 show the breaking forces and adhesive strengths measured with different adhesives and materials for the material composites tested in studies A and B. It can be seen that the fluctuation ranges for the measured adhesive strengths increase as the strength of the bonds increases. However, the standard deviations of the bond strengths obtained using a centrifuge tend to be smaller than the deviations obtained in a tensile testing machine. This was shown by Pfuch et al [1], among others, and attributed to the fact that when using a tensile machine, even the smallest deviations from the axial alignment of the specimen, which must be manually clamped on both sides, lead to a reduction in the measured tensile strength.

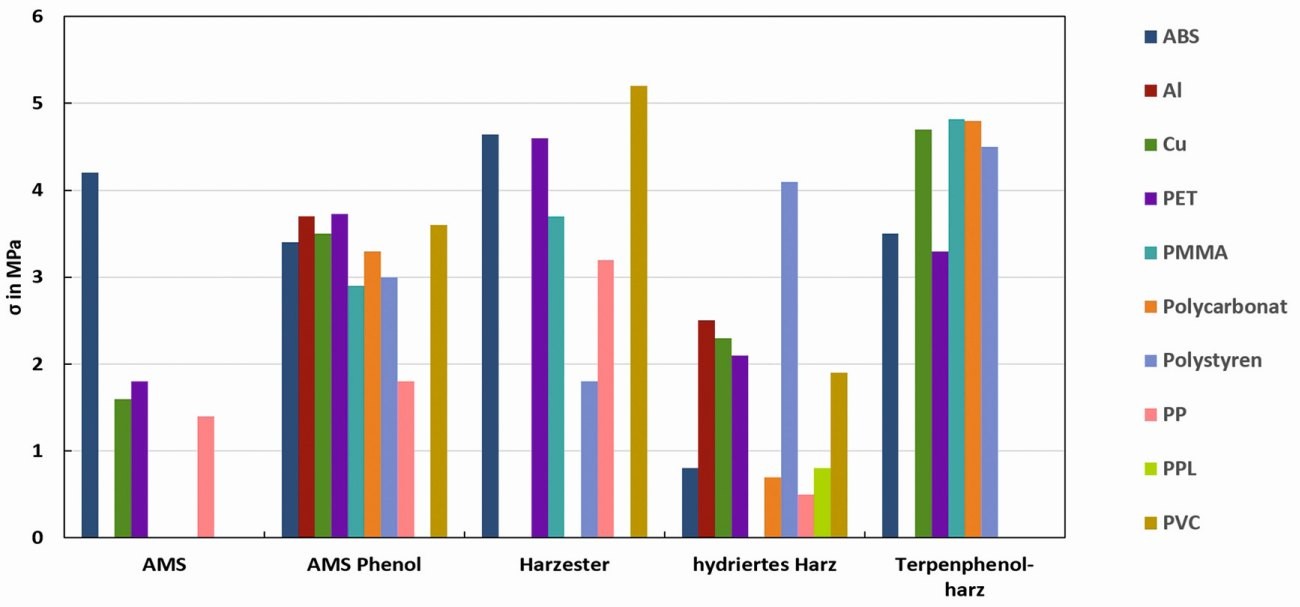

In study C, a number of hotmelt adhesives were tested for their suitability for bonding aluminum to various metallic and non-metallic substrates. Figure 7 shows the results obtained for five different adhesives.

Fig. 7: Comparison of the adhesive strengths of different hotmelt adhesives in the bonding of an aluminum test stamp with different substrates (Study C )

Fig. 7: Comparison of the adhesive strengths of different hotmelt adhesives in the bonding of an aluminum test stamp with different substrates (Study C )

Investigation of the fracture behavior

A material bond breaks at its weakest point. In the case of an adhesive bond, this is either the adhesion at the contact surface between the adhesive and the substrate or stamp surface or the intermolecular cohesion within the adhesive layer. In the first case, this is referred to as adhesion failure, while the breaking of the material bond within the adhesive layer is referred to as cohesion failure. In many cases, combinations of both types of fracture can also be recognized. Figure 8 shows examples of a material failure that is a combination of adhesive and cohesive fracture. In both cases, adhesive-free zones and zones with adhering adhesive can be seen on the test stamp. In the fractures shown in the picture on the right, it can also be seen that the cohesive fracture portion clearly predominates and that the few places where adhesive has detached from the surface of the stamp are obviously caused by air bubbles. These are test specimens with the two different adhesives from study B.

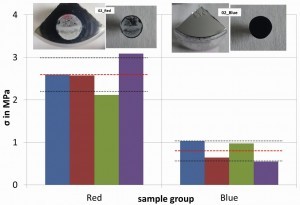

Determining the adhesive strength of coated samples

The following application deals with the layer adhesion strength of metal-coated polymers [2]. Lids for packaging of cosmetic products from two different production stages ("Red" - intermediate product stage; "Blue" - complete coating system) were examined. The aim of the test was to differentiate between the two groups. Furthermore, the extent to which additional layers of the multi-layer coating system influence the surface properties was to be investigated.

One lid of each sample group was divided into four pieces. The metal-coated surfaces were then cleaned with ethanol. Adhesive adapters made of an aluminum alloy with diameters of 10 mm were used for the test stamps. Before bonding, these were sanded and also cleaned with ethanol.

A 2-component epoxy resin adhesive was used. After extrusion from the double cartridge using a static mixing tip, the epoxy resin was applied to the adapter surfaces with a small spatula, which were then placed and pressed onto the sample surfaces. Before testing, the bonded joints cured at 22 °C for approximately 20 hours. Grounding bodies were screwed onto the adapters, the guide sleeves were fitted and the test specimens were then placed in the detection modules. The loaded modules were then inserted into the rotor. A linear force increase of 5 N/s was selected for the measurements.

Figure 9 shows the determined strengths and exemplary fracture patterns in the upper area. The "Red" sample group has an average strength of 2.6 ± 0.4 MPa, with large-scale detachment of the metal coating. The average strength of the "Blue" sample group is significantly reduced (0.8 ± 0.24 MPa) and shows adhesive failure of the adhesive to the coating system. The results illustrate the anti-adhesive properties of the top protective layer of the multilayer system of the "Blue" sample group, while the coatings of the samples of the intermediate stage group "Red" (without protective layer) could be detached at higher strengths.

Possible uses within the bonding process chain

The analytical centrifuge offers the possibility of validating all processes in the bonding process chain. In addition to comparing the suitability of different adhesives in connection with specific materials, the adhesive application process, including pre-treatment, can also be optimized for a specific composite of substrate, adhesive and stamping material. In particular, variations in the preparation of surfaces to optimize adhesive adhesion and the optimization of parameters such as the temperature during adhesive application or curing are possible. The simple handling of the test specimens and the simultaneous analysis of up to 8 specimens at the same time now make it possible to carry out test series within the process chain that would be too time-consuming and labor-intensive if a tensile testing machine were used.

In addition to the simple determination of adhesive strength with standardized short-term tests, the centrifuge offers further options. The possibility of temperature control between -11 °C and +40 °C and the programming of time-dependent load cycles with a maximum test duration of 99 h allow practical load scenarios to be generated and the fatigue behavior of material composites to be investigated.

The multi-sample concept of the analytical centrifuge has now been extended to the pre-treatment of the surfaces to be bonded and the joining of the test specimens as part of a cooperation project funded by the Federal Ministry for Economic Affairs and Energy. At the Federal Institute for Materials Research and Testing (BAM), one of the project partners, devices for the simultaneous treatment of 8 samples based on a universal sample plate were developed and tested for both substrate pre-treatment and test specimen production [1].

Literature

[1] A. Pfuch; U. Beck; T. Lange; U. Rietz; B. Küzün; R. Twardygrosz: How bonds can be validated more easily, adhäsion 9/2015, 44-52

[2] U. Rietz; D. Lerche; S. Hielscher; D. Grunwald; U. Beck: CAT technology as a new multi-specimen method for the determination of bond strengths, Berichtsband Tagung Werkstoffprüfung 12/2017