Cold plasma is increasingly being used in the electrical industry to optimally prepare the surfaces of a wide range of materials for adhesion processes. This can be used to treat functional surfaces on plastics, metals or composites to improve subsequent processes such as bonding, painting or printing.

The piezobrush® PZ3 cold plasma handheld device offers the possibility of uncomplicated and manual optimization. The heart of the device is the piezoelectric plasma generator CeraPlas from TDK. It transforms a small input voltage highly efficiently by several orders of magnitude so that a cold plasma can be ignited under room conditions (less than 50 °C) without the addition of special gases.

A wide variety of materials and material combinations are used to encase electronic assemblies and devices, for example. In order to protect the electronics from external influences and contamination, stable bonding of housing shells is of the utmost importance. This can be specifically improved with cold atmospheric pressure plasma by introducing polar groups.

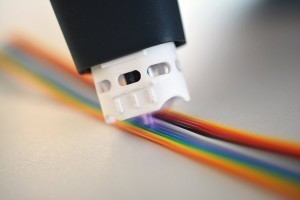

Other application examples include the plasma pre-treatment of batteries or fuel cell components as well as flat ribbon cables.