Plasma chemical oxidation (PCO) is suitable for light metals such as aluminum, magnesium and titanium in order to produce black, light-absorbing and matt surface layers. Such coating systems are already standard, particularly in the optical industry and in laser technology. Although plastics have many advantages over light metals, they are only accessible through an additional modification of plasma chemical oxidation. A new approach consists of applying an aluminum layer to the plastic surface using atmospheric cold plasma spraying and then converting it into an oxide ceramic layer using PCO. This approach makes it possible to combine the advantages of plastics and the property profile of PCO layers, thus opening up new areas of application.

Plastics and their applications have permeated a wide range of industries for decades. Due to numerous innovations in the field of material development and processing technologies, this trend appears to be unbroken. The high degree of design freedom, good processing properties and low density are increasingly making this class of materials an economical alternative in the field of high-performance applications and lightweight construction. Plastics can already be used to replace construction materials such as metals or glass [1].

In addition to the advantages mentioned, plastics are sensitive in their origin, e.g. to frictional stress or thermal stress. This can be counteracted by a targeted application-optimized surface coating. According to the state of the art, metallic coatings play an important role here. Following this approach, the combination process presented deals with the surface functionalization of construction and high-performance plastics. In order to make these accessible for optics or laser technology, for example, a coating technology was developed with which a black anti-reflective layer can be realized on a plastic. In a first step, an aluminum layer is created on the plastic using cold plasma spraying. In a second step, this is converted into a ceramic anti-reflective coating using plasma chemical oxidation.

Plasma chemical oxidation (PCO) or plasma electrolytic oxidation (PEO) has been a proven process for the surface treatment of light metals for a wide range of applications for many years. Inorganic anti-reflective coatings produced using plasma chemical oxidation play an important role both in the optics industry and in laser technology, as well as for use in space technology. The matt black surfaces can be used to minimize the scattered light effects of excimer or neodymium YAG lasers in a wide wavelength range. Compared to organic paint coatings, a PCO coating offers the advantage of greater long-term resistance under extreme operating conditions such as high temperatures, radiation and corrosive loads. In addition, PCO coatings do not contain any volatile organic components due to their composition. Typical device components that are functionalized with the PCO process according to the state of the art are beam blockers, screens, housing parts, absorber plates, shutter screens and beam shields [2, 3].

Step by step to the combination layer

It is well known that smooth plastic surfaces pose a major challenge in terms of adhesion to downstream coating processes due to their low surface energy. In order to convert the surfaces of the plastics into a condition suitable for coating, they were pre-cleaned with solvent and mechanically roughened using wheel blasting. For the coating tests, square plastic flat substrates with edge lengths of 50 mm and 100 mm were pre-treated. The thickness of the flat substrates varied between 1 mm and 2 mm depending on the plastic. Polycarbonate (PC), polyoxymethylene (POM) and carbon fiber reinforced plastic (CFRP) were purchased from Rocholl GmbH and various types of polyimide (PI) were supplied by the Ensinger Group.

In wheel blasting, the abrasive is distributed in the blasting chamber via a rotating paddle wheel. The arrangement of the functional elements within the blasting chamber and the superimposition of rotating and swiveling movements of the workpiece holders allow several components to be treated in a time-saving manner. The advantage of wheel blasting is that the surfaces of the components to be processed, including their undersides, are covered by the blasting material and thus receive an optimum surface finish. The result is very uniform and reproducible surface structures with minimal technical and energy expenditure [4]. System technology from BMF GmbH was used for mechanical roughening. In order to remove blasting material from the roughened surfaces, the plastics were blown off with compressed air after wheel blasting, cleaned again in an ultrasonic bath and dried in a heating cabinet.

Following the pre-treatment, a metallization in the form of an aluminium layer was created on the plastic surfaces using cold plasma spraying. Plasma spraying in general belongs to the group of thermal spraying processes in which spray additives are accelerated onto the component surfaces inside or outside of spraying equipment. Depending on the process, different temperatures and spraying speeds are achieved, which significantly characterize the coating process [5].

In cold plasma spraying, the coating process is operated with lower electrical power compared to the conventional plasma spraying process. This requires the use of smaller particle sizes of the spray additives, which in turn enables the production of lower coating thicknesses with this process. Against the background of weight reduction of technical components or lightweight construction applications, this proves to be advantageous. The IC-3 cold plasma spraying system from the Austrian manufacturer Inocon was used to metallize the plastic surfaces, which is shown schematically in Figure 1.

The system works with a centrally arranged tungsten cathode and a nozzle connected as an anode, between which an electrical discharge, the plasma, is generated. The spray additive required to generate the metallization is dosed via the nozzle in the form of powder. The powder particles melted in the plasma are accelerated under defined conditions onto the substrate to be coated and, depending on the process parameters, form an aluminum layer with layer thicknesses in the range of 20-100 µm.

To generate the aluminum layer on the plastic surface, the plasma source was operated in a medium power range between 3 and 5 kW, which also enables the coating of temperature-sensitive plastics without thermal damage. A commercially available aluminum powder with an average particle size D50 of 20 µm was used as a spray additive.

During coating, the flat substrates were moved in a meandering pattern with the plasma nozzle, whereby the substrate was moved relative to the outlet opening of the plasma nozzle by means of a coordinate-controlled X-Y unit. Table 1 shows an overview of the process parameters used.

|

Process gas |

argon |

|

Amperage |

100-200 A |

|

Spray distance |

40-60 mm |

|

Relative movement of the substrate |

150 mm s-1 |

|

Powder feed rate |

3 g min-1 |

|

Grid |

5 mm |

|

Number of passes |

2 |

In a final step, the aluminum layer produced was converted into an oxide ceramic anti-reflective layer using plasma chemical oxidation. Like anodizing, plasma chemical oxidation is one of the anodic coating processes. It can be used to produce inorganic coatings on light metals such as aluminum, magnesium, titanium and their alloys that are very contour-true with regard to the component geometry [6]. This type of coating is a conversion coating in which the substrate material is involved in the coating structure. Such oxide ceramic coatings are used when it is necessary to optimize the property profile of the initial surface of the light metals with regard to the application [7].

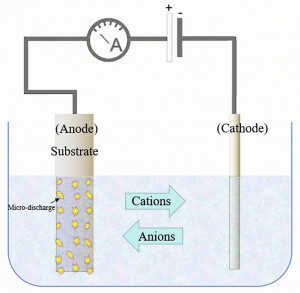

Fig. 2: Schematic representation of the PCO process

Fig. 2: Schematic representation of the PCO process

Figure 2 shows a schematic diagram of a commercial system for the PCO process. It consists of an immersion bath, which contains the electrolyte and is often water-cooled, a high-power electrical source and a pulse generator. The PCO process is usually carried out in an environmentally friendly alkaline electrolyte under various electrical conditions. When the so-called ignition voltage is exceeded, micro-discharges occur on the component surface, which are generally referred to as plasma discharges and under the influence of which the surface can be specifically modified. The component is connected as an anode. The electrolyte facilitates the passivation of the aluminium metallization and leads to the formation of a thin insulating film, which is crucial for the dielectric breakdown and discharge processes [8]. The coating process consists of a number of different sub-processes that are distinctly different from each other, including electrochemical reactions, plasma chemical reactions and thermal diffusion [9]. Electrical parameters such as the waveform and the magnitude of the applied current or voltage, frequency and duty cycle have a complex influence on the properties of the coating [6]. In addition, the formation and properties of the PCO layers are significantly influenced by the composition of the electrolyte used [10]. Extensive research has been carried out in recent years, which has led to considerable progress in the industrialization of the PCO process [6].

In the present case, the aluminum layer produced on the plastic surface was converted into a ceramic layer in a phosphate-containing electrolyte by plasma-chemical means (Fig. 3). The selected electrolyte can be used to produce black coatings in particular, which are typically used as anti-reflective coatings in optics and laser technology due to their morphology.

Fig. 3: Polycarbonate with cold plasma coating (left) and black PCO layer (right )

Fig. 3: Polycarbonate with cold plasma coating (left) and black PCO layer (right )

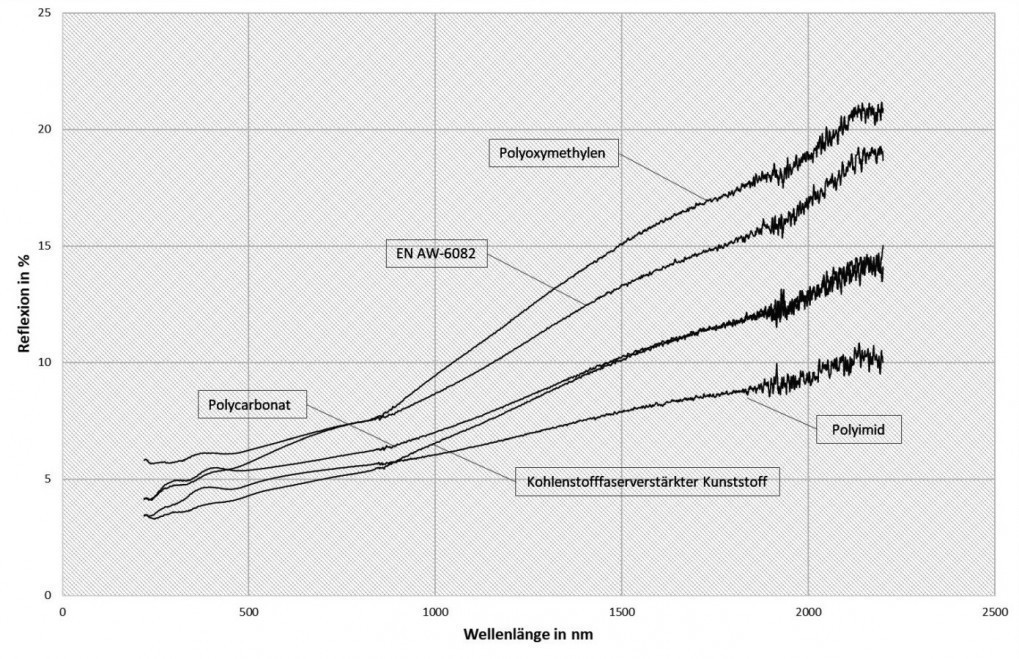

The anti-reflective properties of the coatings were determined by a UV/VIS-NIR measurement using an integrating sphere (Fig. 4). The measurement using an integrating sphere (without light trap) made it possible to determine the total reflectance of the coating. Both the diffuse and the directional part of the reflection were recorded. The spectra were recorded in a wavelength range of 220 - 2200 nm, with a data interval of 1 nm and a scanning speed of 200 nm/min.

Fig. 4: Reflectance spectra of selected coating systems

Fig. 4: Reflectance spectra of selected coating systems

As a reference, the black combination coatings were compared with a commercially available anti-reflective coating for the aluminum alloy EN AW-6082 (Fig. 4). The reference coating is the standard coating system PCO®35 from Sura Instruments GmbH. In general, the reflection spectra of the combination coatings reflect the typical characteristics of the reference coating. The results show that the high-performance plastic polyimide and the carbon fiber-reinforced plastic in particular outperform the anti-reflective properties of the reference.

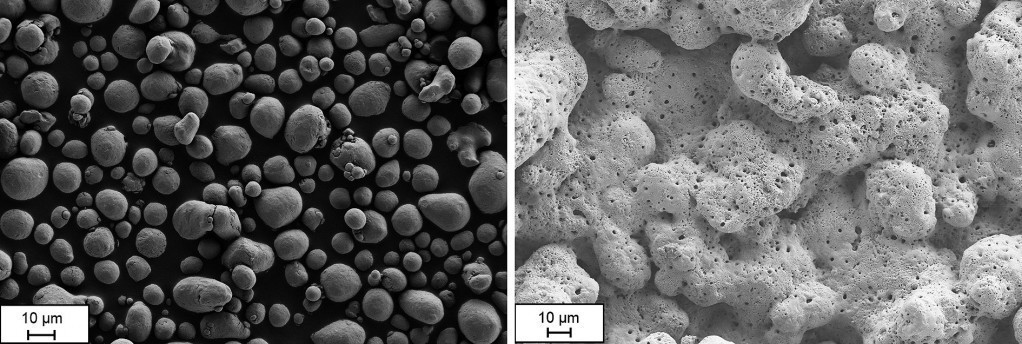

The reflective behavior is significantly influenced by the morphology of the surface. The pores typical of a PCO layer act as beam traps. To clarify the relationships between morphology and reflection behavior, the initial state of the aluminum powder and the combination layers produced on the plastic surfaces were examined using scanning electron microscopy (Fig. 5). The examination of the aluminum powder in its initial state shows that the powder particles have a spherical shape (Fig. 5 left). The particles are evenly distributed and have a diameter in the range of 5 to 25 µm. Due to the relatively low power of 3 kW during cold plasma spraying, the powder particles were not completely melted when the metallization was generated on the plastic surface, so that the spherical initial state of the powder particles can be found in the plasma-chemically oxidized combination layer. In conjunction with the pores typical of a PCO layer, morphological features are superimposed which can be used to specifically influence the reflective behavior.

Fig. 5: SEM image of the morphology of the aluminum powder in its original state (left) and the morphology of the plasma-chemically produced anti-reflective coating on polycarbonate (right)

Fig. 5: SEM image of the morphology of the aluminum powder in its original state (left) and the morphology of the plasma-chemically produced anti-reflective coating on polycarbonate (right)

The start has been made

The production of adhesive anti-reflective coatings on plastic surfaces, especially on engineering and high-performance plastics, provides new material combinations for the realization of lightweight device components for optics, laser technology or aerospace. The investigations have shown that the new combination process can be used to produce high-performance surface functionalities. In a broad-based feasibility study, it was demonstrated that the coating technology can be used to produce anti-reflective coatings on both standard plastics and high-performance plastics.

The temperature input into the plastic and the morphology of the aluminum layer produced can be controlled by adapting the cold plasma spraying process. Consequently, the optical property profile of the surfaces can be specifically influenced with the subsequent plasma chemical oxidation step. The result is high-performance coating systems for the implementation of lightweight construction concepts that meet and even exceed the state of the art in terms of their reflective properties. The research results to date indicate that the novel combination process represents a promising approach for the functionalization of plastic components.

Acknowledgements

Part of the work presented here was supported by the German Federal Ministry for Economic Affairs and Energy (BMWi) under the funding code 49MF200039.

Literature

[1] M. Theunissen: Light and durable: Polymere im

Leichtbau, https://faszinationchemie.de/makromolekulare-chemie/news/leicht-und-bestaendig-polymere-im-leichtbau/, accessed on 10.05.2023

[2] J. Schmidt et al.: The plasma chemical oxidation of light metals for optical and medical

applications, Galvanotechnik, 11, 2012, 2416-2427

[3] U. Bayer et al.: Plasmachemische Oxidationsverfahren Teil 4: Plasmachemische Oxidation von Magnesiumlegierungen - Anwendungen in optischen Geräten und um Fahrzeugbau, Galvanotechnik, 9, 2003, 2161-2168

[4] BMF GmbH: Bernstein Sandblasting Plants,

http://tornado.twister-sand-strahl-anlage.de/funktion-2/, accessed on 05.05.2023

[5] L. Pawlowski: The Science and Engineering of Thermal Spray Coatings, John Wiley & Sons, Ltd, 2008

[6] T.W. Clyne et al: A review of recent work on discharge characteristics during plasma electrolytic oxidation of various metals, International materials reviews, 64.3, (2019), 127-162

[7] R.O. Hussein et al.: Production of anti-corrosion coatings on light alloys (Al, Mg, Ti) by plasma-electrolytic oxidation (PEO), Developments in corrosion protection, (2014), 201-239

[8] F. Simchen et al.: Electrolyte influence on ignition of plasma electrolytic oxidation processes on light metals, Surface and coatings technology, 315, (2017), 205-213

[9] R.O. Hussein et al; An investigation of ceramic coating growth mechanisms in plasma electrolytic oxidation (PEO) processing, Electrochimica Acta, 112 (2013), 111-119

[10] V. Dehnavi et al: Growth behavior of low-energy plasma electrolytic oxidation coatings on a magnesium alloy, Journal of Magnesium and Alloys, 6.3 (2018), 229-237