Cost-effective, future-oriented manufacturing technology for plastic components Requirements for the interior.

Vehicle interiors, especially the cockpit, are equipped with a large number of controls and assistance systems. The buttons, switches and displays in modern vehicle interiors are now very elaborate and stylish in terms of their function and design, and in some cases also in terms of their surface and feel, as they are intended to appeal to all the senses and create a feel-good atmosphere while driving. This is achieved in very high-quality premium vehicles through a special structure and arrangement of the various materials and coatings of the decorative plastic components: although functionality is more of a priority for buttons and switches, the visual appearance is also becoming increasingly important here, especially in high-quality and expensive premium vehicles, e.g. by creating a so-called "glass look" effect. Sometimes gloss and matt effects as well as metallic, mirrored (partial) surfaces also play a decisive role. In premium vehicles, particularly elaborate and natural-looking covers with appealing wood decors are increasingly being used, some of which are made of very high-quality real wood inlays that give the cockpit a cozy ambience. Figures 1 to 3 show examples that were produced using the new process.

The variety of functions and in particular the color design of the control elements and their implementation in the product requires a wide range of manufacturing processes, some of which are very complex and cost-intensive, in order to ensure the required premium quality. The components, which are usually injection-molded plastic parts, must meet the high demands for a sustainable, long service life under very tough operating conditions at all times. We are thinking, among other things, of cleaning chemicals, skin perspiration and various creams, such as skin and sun cream - as well as everyday stresses caused by mechanical abrasion and scratching, or the stressing of surfaces and materials by sunlight, even if these plastic components in the interior of vehicles are significantly reduced compared to the stresses to which exterior components are exposed, they should not be completely neglected. The quality requirements of all vehicle manufacturers are therefore extremely high and every new component has to pass an extensive, demanding test program in accordance with the various factory standards before it can be installed in a series vehicle. For suppliers, market access is virtually impossible without a corresponding quality certificate.

State of the art and its limits

The state of the art in the automotive industry and its suppliers is the predominant use of PMMA in injection molding for plastic components, especially in the piano black surface finish, because PMMA already has a relatively hard surface that is largely resistant to abrasion and scratches, even without a coating.

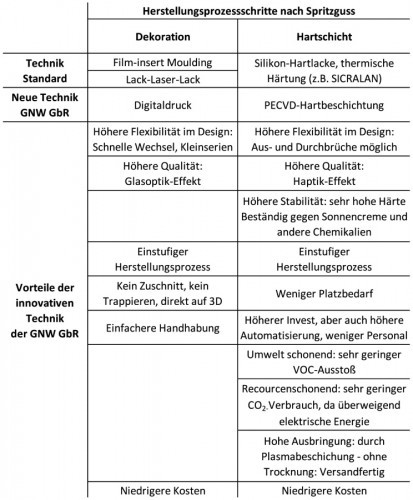

The incorporation of decorative and functional elements, such as symbols, numbers and letters, illuminated fields in various colors, but also the flat, usually black base surface, has so far mainly been achieved by bonding or laminating the injection-moulded components, e.g. with additional, appropriately printed and/or metallized polymer films. These processes - such as film insert molding (FIM) or the lacquer-laser-lacquer process - are very complex, cost-intensive and inflexible, as they only allow high quantities of a design and are only really profitable in this way. Digital printing directly onto the surface of the component offers a modern, much more flexible and therefore more economically attractive alternative. Controlled directly via the PC, design templates can be changed very quickly and therefore even small batches - in extreme cases even individual pieces - can be produced to customer specifications with extremely low logistics and material costs and fed to subsequent production steps, such as coating.

Tab. 1: Comparison: conventional and innovative technologies

Tab. 1: Comparison: conventional and innovative technologies

With the increased demands placed on the finishing of today's surfaces, however, PMMA is becoming less and less suitable, so that polycarbonate (PC) is increasingly being used as a substitute. Although PC as a base material is somewhat more temperature-stable and less brittle, additional surface protection is required, usually by means of a scratch-resistant finish with transparent acrylic or silicone lacquers (1 or 2-component lacquers), applied in a flood or spray process and usually thermally cured, more rarely with UV. The thermal process in particular requires a great deal of effort to avoid and dispose of the VOCs (volatile organic compounds) produced, as these substances, which are harmful to the air and ozone layer, must be kept at a very low emission level in accordance with BIMSch. The curing of the paints and the post-treatment of the VOCs generate a highCO2 footprint for this technology, which will therefore become less and less economical in the future when new climate protection regulations come into force. A much more sustainable, environmentally friendly and resource-saving alternative is now available in the form of plasma CVD technology. It works with extremely small quantities of chemicals, almost exclusively with electrical energy, which can be obtained from renewable sources, and is essentially free of VOC emissions. It also offers further advantages in the manufacturing process and parts handling as well as the associated logistics in the production chain. Following significant improvements in the coating process and in the technology of automated coating systems, this innovative technology also represents a viable and expectedly profitable alternative to traditional painting processes in terms of costs. Table 1 provides a comparison.

An innovative combination process

The three founders of GNW innovative Oberflächenveredelung GbR Detmold joined forces on the initiative of Managing Director Jan Wisomiersky to bring this new technology into production and onto the market together with partners. Wisomiersky had the idea of combining these three individual technologies in an innovative manufacturing process. The challenge was to find a digital printing process that could be coated well in the plasma CVD process and still guarantee the color fastness and stability of the ink layer and the layer composite. The development ended successfully with the granting of patent DE 10 2016 015 044 B4 and the founding of the company with the two partners: Frank Gerstenberger, an injection molding expert - and Dr. Klaus Dieter Nauenburg as an expert in plasma CVD.

The glassy plasma CVD protective layer made of SiOx has been continuously developed over the last 25 years [1-7]. First, the microwave-based plasma CVD process was optimized to a high coating rate of several micrometers/minute, which is competitive with conventional hard coating systems - currently up to 12 µm/min are possible - but in this case approx. 6 µm/min and scaled up to a fairly uniform coating thickness distribution over large areas of at least 0.5 m² - up to 2 m² are quite possible. Subsequently, the focus was on optimizing all coating properties for the various applications. In particular, the guarantee of coating adhesion and freedom from cracks over the entire service life of the components under alternating temperature and humidity loads was a major challenge, which was then mastered a few years ago through minor modifications in the PECVD process. It turned out that these SiOx layers are also good barriers that are highly resistant to chemicals and can reliably solve the problem that conventional protective layers made of hard coatings are relatively easily attacked and damaged by the ingredients of skin and sun creams. Furthermore, these coatings showed sufficient resistance to UV light and withstood the mild weathering test, which must be passed for interior components, with good results - although no additional UV protective layer had to be incorporated into the coating package for this purpose, which will certainly still be absolutely necessary for exterior vehicle components despite all the progress made in optimizing plasma CVD scratch-resistant coatings, e.g. for plastic windows made of PC.

Quality assurance

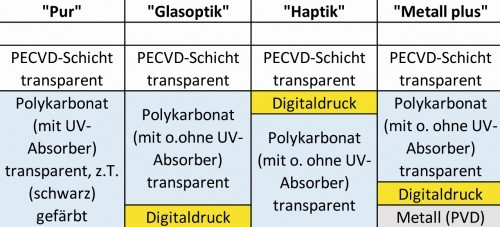

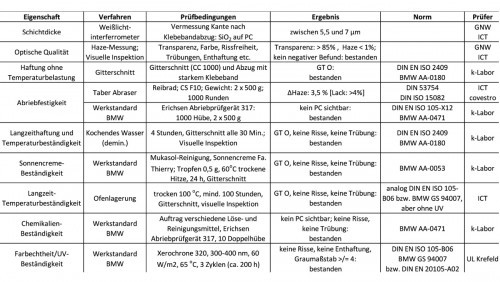

All these advances in printing and plasma coating technology encouraged the founders of GNW to bring this new production technology to market maturity. In addition to the search for partners in the plastics sector (material and injection molding), digital printing technology and mechanical engineering (vacuum system manufacturers), it was particularly important to provide proof of quality for the essential requirements of the automotive industry for plastic interior components. The test certificates now available from two certified test laboratories confirm that complete components - i.e. both the so-called "glass optics" and the so-called "haptics" structure, as well as PC components without printing - meet the requirements of the car manufacturer's factory standard. Table 2 shows possible coating systems. Table 3 provides an overview of properties and test results.

Optimization of application, costs and sustainability

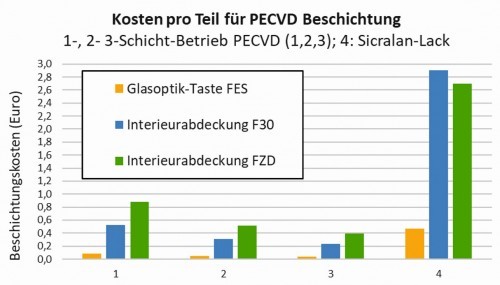

The successful result of the PC sheets with a wood decor (see Fig. 3) was particularly pleasing: printing with different colors creates a rough, textured surface with the feel of a wood grain. This allows the plastic component to imitate real wood. The transparent hard coating using plasma CVD can - in contrast to painting - retain the surface structure. Embossed or printed surfaces retain their "matt" effect. It can also reliably coat openings and edges on the flanks without defects, as it is all-encompassing. Metal mirrors can also be easily accommodated in the decorative layers, as sputtering or vapor deposition can be easily integrated into the existing plasma CVD vacuum production line. As the components are dry after plasma CVD coating, they can be packaged and shipped immediately. In addition to these advantages in terms of component quality and logistics, rough calculations of the manufacturing costs - individually for each of the three production steps - have revealed a large potential for cost savings. In order to be on the safe side, rather cautious approaches and assumptions were initially made, e.g. regarding output and utilization rates, investment and material costs. Although the investment costs for vacuum systems, for example, are relatively high, the operating and labor costs are ultimately much lower compared to the state of the art due to the high degree of automation, as the cost comparison in Diagram 1 shows. The considerably lower disposal costs and the possibility of climate-neutral energy procurement for this type of production machine, which requires almost exclusively electrical energy, enables an almost climate-neutral type of production. And interior components made of plastics will continue to be in demand in the future: especially in carbon-free and highly digitized vehicles, lower weight and more sophisticated interior equipment and comfort will play an increasingly important role for users and customers.

Summary

With the combination of injection molding, digital printing and plasma CVD hard coating, a sustainable, virtuallyCO2-free and even more cost-effective alternative process is now available for plastic components that reliably meets all quality requirements for use and design - for interior components of vehicles, but also for use in "white goods" or furniture, for example.

Literature

[1] W. Petasch; E. Räuchle; H. Muegge; K. Muegge: Surf, Coat. Technol. 93, 1997, 112

[2] M. Walker; K.-M. Baumgärtner; M. Kaiser; A. Schulz;, E. Räuchle: Vacuum 57, 38

[3] R. Beckmann; K.-D. Nauenburg; T. Naumann; U. Patz; G. Ickes; H. Hagedorn; J. Snyder: SVC, 44th Ann. Tech. Conf. Proc., 2001, 228

[4] T. Schmauder; K.-D. Nauenburg; K. Kruse; G. Ickes: Thin Solid Films 502, 2006, 270

[5] K.-D. Nauenburg; T. Schmauder: Wipe and scratch resistant coatings on plastics for decorative and optical applications, Metalloberfläche, 7-8/2004, 58. Jahrgang, Juli 2004, 31-33, Carl-Hanser-Verlag, München

[6] K.-D. Nauenburg: Glass-like functional coatings by plasma CVD: Hard, decorative, temperature-resistant and corrosion-resistant!, Jahrbuch Oberflächentechnik, ed.: R. Suchentrunk, Eugen G. Leuze Verlag KG, Bad Saulgau, 2008, vol. 64, 167-177

[7] K.-D. Nauenburg; R. Drehe; J. Stammler: Glasartige Funktionsschichten durch Plasma-CVD - Teil 2: Vereinfachtes und dauerhaftes Fügen von Leichtbaustrukturen mittels haftfester und korrosionsbeständiger Plasma-CVD-Beschichtungen, Jahrbuch Oberflächentechnik, ed.: R. Suchentrunk, Leuze Verlag, Bad Saulgau, 2013, Vol. 69, 203-217