Due to their low weight and high load-bearing capacity, fiber-reinforced plastics (FRP) are being used in more and more applications.

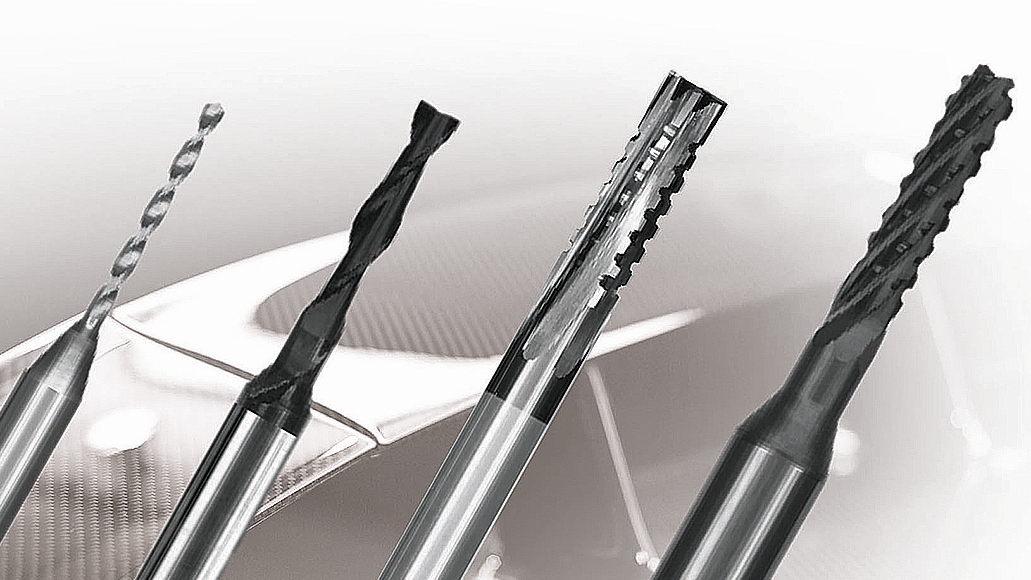

The tool experts at HPTec GmbH in Ravensburg have developed the new "HPTec Composite Tool Action" micro-milling cutters with a view to maximum process reliability and component quality. An important component of this is the CemeCon diamond coating based on CCDia®AeroSpeed®.

Composites such as CFRP or GFRP consist of several layers. Their inhomogeneous material structure with hard and highly abrasive fibers and a thermally sensitive matrix poses particular challenges for machinists. Delamination and fiber protrusions weaken the structure. This is why they must be avoided at all costs during machining. A high cutting edge quality and the wear resistance of the cutting material play a decisive role here. Carbide tools with the CCDia®AeroSpeed® multilayer diamond coating from CemeCon have proven to be the best approach for reliable and economical machining. This has an extremely smooth and ultra-fine crystalline surface topography, excellent adhesion and quickly dissipates frictional heat from the contact zone. With a hardness of around 10,000 HV0.05, the coating offers excellent resistance to high-strength and highly abrasive fibers, thus ensuring a long service life for the tools. Thanks to the patented multilayer structure, the diamond coating also has crack-stopping properties.