Martensitic chromium steels are ideal for applications in vehicle construction due to their lightweight construction and corrosion properties. These materials are particularly in demand for the construction of crash-proof battery boxes for electric cars.

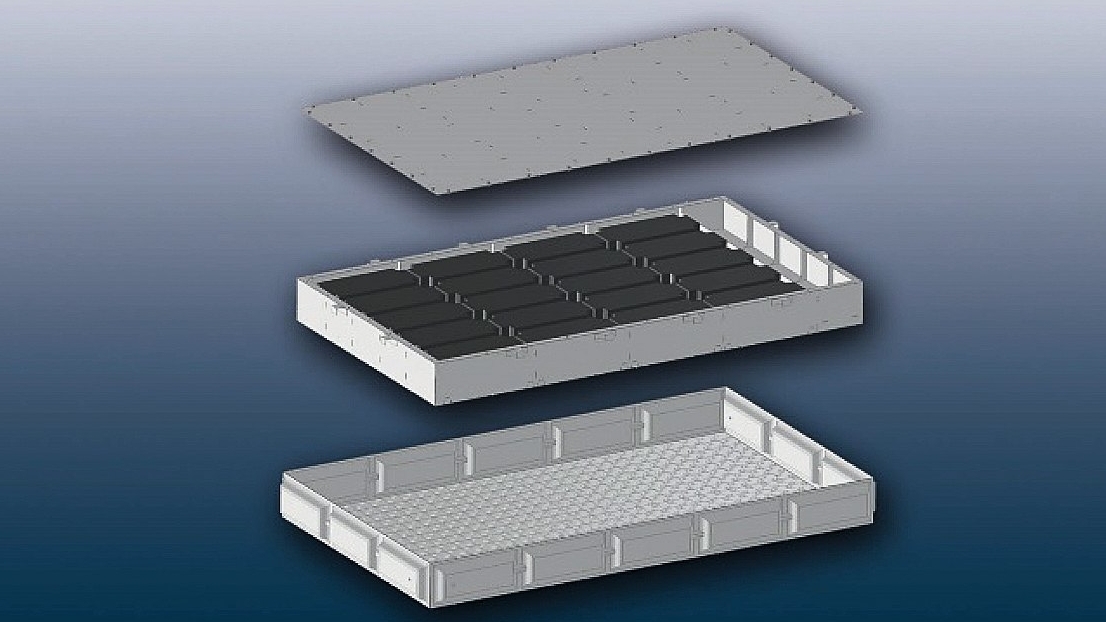

As part of the AiF research project FAAM, funded by FOSTA - Forschungsvereinigung Stahlanwendungen e.V., Fraunhofer ILT and its partners investigated the suitability of a press-hardened chromium steel with a martensitic microstructure X46Cr13 (1.4034) for welding in similar and dissimilar joints for assembly. The work was able to show that not all dissimilar steels are suitable for welded joints. However, they also showed that work-hardened austenite and cold-rolled fine-grained structural steel cannot be heat-treated by laser. These findings will serve as the basis for the calculation and design of a battery box with an attached crash frame. The module carrier consists of a material mix of ultra-high-strength and supraductile steels. Thanks to this combination, the empty weight of around 70 kg is significantly less than conventional steel battery boxes, which weigh up to 150 kg in integral design.