Plasma quenching for the formation of nanoparticles uses a cyclical increase in the prevailing pressure in the vacuum chamber in sputtering processes. In the case of carbon (C), a significant reduction in the coefficients of friction on various substrates was achieved using a typical industrial magnetron sputtering system and cathode sputtering. While Part 1 presented preliminary considerations and some of the experiments, the second part supplements the experimental implementation and then focuses on the resulting findings. The final part in the next issue will mainly deal with the discussion and conclusions from the experiments.

Experiments

3D printed substrates made of semi-crystalline polyamide 12 (PA 650, ALM LLC, USA) were used for the coating development by means of selective laser sintering (SLS). Their melting point is 181 °C (ASTM D3418-181), the dimensional stability temperatures (ASTM D648-177) are 177 °C (0.45 MPa) and 86 °C (1.82 MPa) respectively, the tensile strengths (ASTM D638) are 48 MPa with a tensile modulus of 1.7 GPa and 24% elongation at break in the sintering plane. The samples were printed in an upright arrangement with X x Y x Z = 50 x 2.5 x 50 mm geometry at Rapid Product Development RPD GmbH (Kapfenberg, Austria) using established industrial manufacturing processes. The sintered samples have uncoated roughness values ofRa ~ 10 μm, Rq ~ 12.5 μm, Rz ~7.5 μm in the X-Z plane, which was also used for the tribological tests. In addition, austenitic stainless steel substrates (Cr-Ni 18-8, 1.4301) with a polished surface (Ra <0.03 μm) and silicon wafers (Ra <0.01 μm) were also used.

The industrial-style magnetron sputtering system from Joanneum Research (Oerlikon Leybold UNIVEX 450 B, photo on p. 488 in Galvanotechnik 4) was used for MoS2/DLC coating on the SLS polymer substrates. The system has 4 sputter cathodes arranged in a closed field, an anode layer source and a central carousel for substrate assembly with the option of triple rotation on planets, although only the substrate disk was rotated in the investigations.

Before high-vacuum coating, the substrate surfaces were cleaned and degreased using industrial cleaning equipment (Miele IR6002, Gütersloh, Germany) with washing surfactants tailored to polymers and then dried in a vacuum oven. After charging, vacuum in the range of 10-5 mbar was applied via a two-stage pump system. The coating is applied after pre-treatment in a reactive plasma (Anode Layer Source, Veeco Inc., Fort Collins, USA) for surface activation to increase adhesion. During the coating process itself, 2 MoS2 targets are simultaneously "sputtered" with DC voltage and ionized. The vapour (plasma) from MoS2 is then deposited on the material surface with the addition of acetylene, which is also ionized by the plasma, into the chamber. As a specific feature of plasma quenching, the chamber pressure was significantly increased at cyclic intervals (5 min) for 1 min by means of a freely adjustable vacuum valve (VAT slide), resulting in a significantly increased number of collisions in the plasma (according to simulations, about 20-30 times higher collision frequency). Increased collision probability thus leads to increased formation of agglomerates in the plasma (see Fig. 1 Electroplating technology 4) and their deposition on the surface, resulting in the formation of a multilayer coating type consisting of carbon and MoS2 individual layers deposited on the substrate at higher and lower energy due to the specified cycle. The coating parameters used for plasma quenching and without the use of pressure surges are listed in the results section.

The coating characterization was carried out with thickness and roughness measurements using a stylus profilometer (Veeco Dektak 150), with scanning electron microscopy (SEM, Tescan) to analyze the surfaces, cross-sections and wear marks and with energy-dispersive X-ray spectroscopy (EDX, Oxford Instruments) for the quantitative coating composition. Linear tribology tests (Anton-Paar MicroScratch Test MST) used reciprocal grinding of a 6 mm Al2O3 ball over 1000 cycles on 8 mm linear sliding path with simultaneous analysis of friction coefficient and indenter penetration depth. The load force used in the linear tribology tests was 2 N to reduce the test duration and to simulate significant overloading of the PA12 substrate, resulting in very high surface pressure and high local heat generation in the polymer due to elastoplastic deformation.

Results and discussion

As a starting point for the investigations on plasma quenching and its effects on the tribological behavior on polymer and metal substrates, coatings deposited at constant pressure conditions and without pressure surges were examined, which were produced at 2 kW sputtering power on the stoichiometric MoS2 target at different constant gas flows according to Table 1.

|

Chemical composition |

|||||

|

Gas flow [sccm] |

Coating thickness [µm] |

C [Atom%] |

S [Atom%] |

Mo [Atom%] |

Mo:S |

|

1 sccm C2H2 |

4,1 |

39,5 |

37,6 |

22,8 |

0,61 |

|

5 sccm C2H2 |

4,1 |

45,4 |

33,3 |

21,3 |

0,64 |

|

10 sccm C2H2 |

4,2 |

50,8 |

30,9 |

18,3 |

0,59 |

|

15 sccm C2H2 |

4,2 |

62,6 |

23,2 |

14,2 |

0,61 |

These coatings show a similar, slightly over-stoichiometric ratio of Mo and S (equilibrium stoichiometry: Mo:S = 0.5), i.e. light sulphur atoms are lost from the plasma during sputtering. Asthe supply ofC2H2 increases, the carbon content naturally rises, although this increase is not linearly proportional to the partial pressure of C2H2 and thus to the supply of C-containing species. Rather, a very high C content of just under 40 atom % is initially found at 1 sccm, but this only increases by about half when theC2H2flux is increased 15-fold. Therefore, only a small part of the available C2H2 can be used for sputtering, while a large part is not dissociated in the plasma by collisions with argon ions or atoms, sputtered MoS2 species or CxHy and is extracted via the vacuum pumps. A significant change in the deposition rates (typically in the range of 19 to 21 nm/min) was also not observed. In order to maintain the same final pressure, the argon flow was reduced so that a total gas flow of 50 sccm was always achieved. Less argon sputtering gas flow reduces the sputtering rate of the MoS2 target, which also triggers a reduction in collisions between argon particles accelerated in the magnetic field and C2H2moleculesfrom the process gas. An SEM image of the surface - using a layer defect for good focusing of the surrounding layer surface - shows very smooth surfaces apart from these very isolated "flitters" on the surface (see Figure 5 in the next issue). However, the tribological properties that can be achieved are relevant to the application and are shown in Figure 3 for unlubricated, "dry" sliding against Al2O3 mating bodies on coated PA12 and steel substrates. First of all, the strong dependence on the substrate can be seen. Due to the same coefficient of friction at the beginning of the contact in the run-in, with a subsequent increase for PA12 and austenite, it can be assumed that the main influence is due to the roughness, which is about 100 times higher for the PA12 substrate. Finally, friction coefficients of 0.3 to 0.4 for PA12 (which has uncoated friction coefficients in the same range against Al2O3 under these conditions) and of 0.16 to 0.22 for austenite (uncoated: 0.6 to 0.7) can be seen in the steady-state range. The penetration depth is always positive for the PA12 substrates, i.e. the friction-induced heating causes the polymer substrate under the coating (or also the 1 sccm C2H2coatingon the austenite) to expand. As the penetration depth is measured during the measurement, these values directly represent the material behavior of the composite. A comparison of the individual layer types shows that medium carbon contents orC2H2fluxes(5 or 10 sccm) on austenite exhibit the optimum frictional behavior, but very lowC2H2fluxes(1 sccm) also have a favorable effect on PA12. Low friction is accompanied by a tendency towards low penetration depth (erosion or heating).

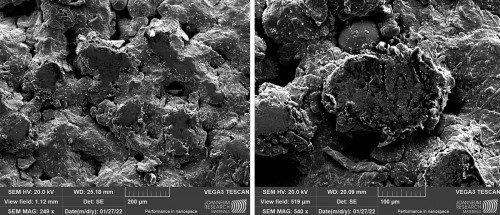

Fig. 4: SEM analysis of the layer deposited at 5 sccm C2H2 on PA12 after 1000 linear tribology cycles

Fig. 4: SEM analysis of the layer deposited at 5 sccm C2H2 on PA12 after 1000 linear tribology cycles

Optical microscope images show that the contact initially only occurs on the peaks of the roughness, but these PA12 peaks are then thermally ablated and polished smooth, which locally increases the reflection of the surfaces. With a higher C2H2flux, the contact areas initially become more "contiguous" and larger after 1000 passes, but later (at very high fluxes) become more isolated again. The detailed analysis of the occurring wear phenomena with SEM images is discussed below (Figure 4): Here, the ablated peaks of the porous, rough SLS surface in wear contact can be clearly seen. Only around 10-20% of the surface is in direct contact with the Al2O3 sphere after 1000 cycles, which triggers extremely high local surface pressures far above the macroscopic compressive and shear strength of the PA12. These lead very quickly to a deformation of the plastic, which explains the increase in the coefficients of friction starting with the first contacts in the run-in very well. As a result of cyclic and direction-changing movement, the polymer sintered grains in contact are disrupted, as can be seen very clearly in Figure 4 (right). Also clearly visible is the deformation of the grains in both directions (left and right) with deposition of the softened and sheared material volumes at the ends of the local contact. The coating itself is very easy to recognize and also shows only a few cracks in the areas of the "necks" of the sintered grains, which are usually very strongly elastoplastically deformed. The deposition of the layer, which appears lighter than the polymer, on the contact surfaces can also be seen to some extent. In general, however, contact is made directly on PA12.