High-power diode lasers with outputs of ten kilowatts and more open up new application scenarios for laser metal deposition. This enables particularly sustainable and resource-saving coatings, for example in automotive construction, mechanical engineering and other industries.

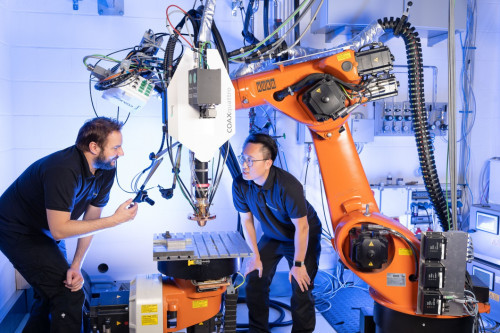

A core element of the HICLAD® family is the innovative COAXquattro laser cladding head. A laser beam runs through the center of the nozzle, around which up to eight separately controllable channels feed powder and wires. The flexible capabilities also save material costs, because materials in wire form are often only half as expensive as in powder form. (Photo: Fraunhofer IWS)

A core element of the HICLAD® family is the innovative COAXquattro laser cladding head. A laser beam runs through the center of the nozzle, around which up to eight separately controllable channels feed powder and wires. The flexible capabilities also save material costs, because materials in wire form are often only half as expensive as in powder form. (Photo: Fraunhofer IWS)Together with partners from industry, the Fraunhofer Institute for Material and Beam Technology IWS has now developed applications and specific processes under the Hiclad label for this class of industrial lasers to practical maturity.

A core element of the label is the COAXquattro laser cladding head. A laser beam runs through the center of the nozzle, around which up to eight separately controllable channels feed powder and wires. The flexible capabilities save material costs because materials in wire form are often only half as expensive as in powder form. Today, diode lasers with outputs of up to 20 kilowatts and more enable much higher deposition rates of up to 18 kilograms per hour in industrial applications, depending on the specific material and the nozzle selected. The next step will lead to the 45-kilowatt class.