Whether for wind farms, coastal protection structures or in harbors, when technical structures have to be welded underwater, this is usually done by divers using manual electrode welding, which has various disadvantages.

Together with AMT GmbH from Aachen, the Laser Zentrum Hannover (LZH) is developing a laser-assisted metal filler wire welding process for use under water. The process is intended to facilitate underwater welding work and produce better weld seams. However, the burnt electrodes have to be replaced frequently.

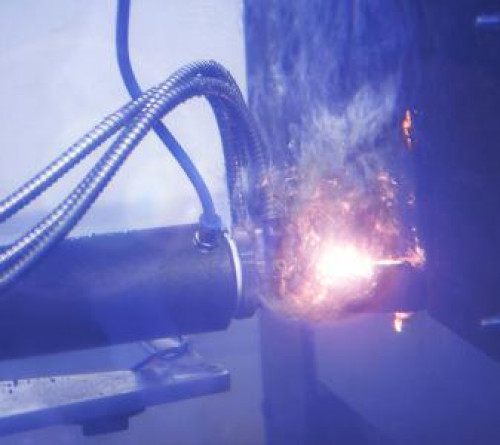

In flux-cored wire welding, on the other hand, wire can be continuously fed from a wire reel and melted. The LZH now wants to further optimize flux-cored wire welding by using laser support. The laser beam will introduce energy into the workpiece in a targeted manner in order to improve arc ignition and stability. The targeted combination of laser beam and arc in a common process zone allows the arc to be guided precisely, resulting in greater process stability and geometric accuracy of the welding seam.

In the LaMeer project, the partners now want to investigate the combination of laser beam and arc in use under water. To this end, they want to develop and test a welding torch prototype with integrated laser optics.