Milling carbides instead of eroding or grinding them has enormous advantages: shorter cycle times, better surface quality, more environmentally friendly machining, no corrosion and the production of more complex contours. The fact that the numerous advantages of machining are not currently used more frequently is not least due to the difficult machinability of sintered carbides.

Degrees of hardness between 900 and 2,200 HV, high wear resistance and heat hardness require extremely powerful and stable precision tools.

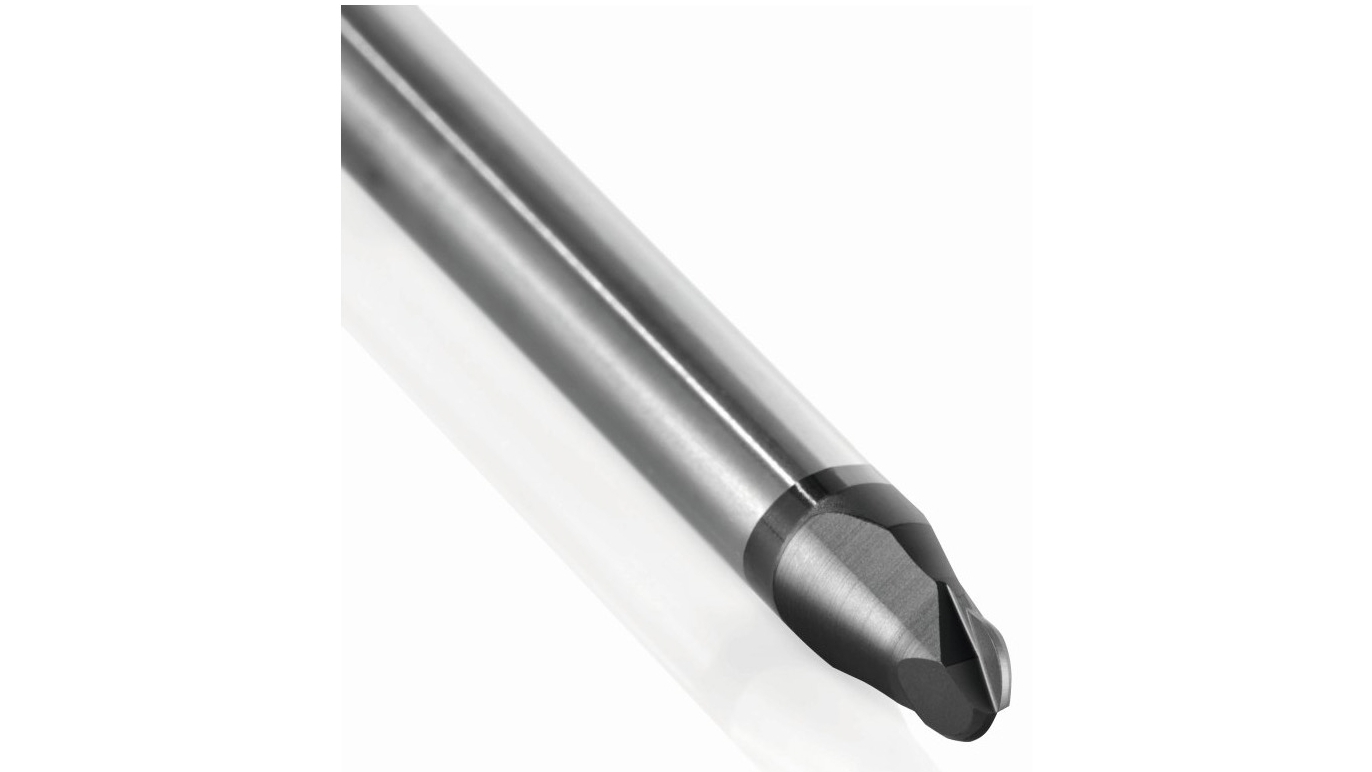

With the newly developed CCDia® CarbideSpeed®, CemeCon is now providing tool manufacturers with a precisely matched diamond coating material that creates ideal conditions even for the toughest operating conditions and thus enables users to machine carbide economically. It combines maximum adhesion with a microhardness of 10,000 HV₀,₀₅ for maximum wear resistance. The first pilot projects have already shown that precision tools with this coating achieve at least the same, and in most cases even better, performance in terms of productivity and cost-effectiveness than existing solutions. Series production has now begun.