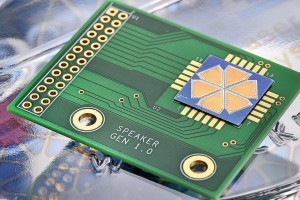

It has six corners and is about the size of a 1-cent piece: in an additive manufacturing process, miniature loudspeakers can be produced efficiently and cost-effectively as part of piezoelectric, microelectromechanical systems - so-called piezo MEMS - using thin-film technology with a combination of inkjet printing and laser technology.

The individual loudspeaker elements are then separated and integrated into an electronic environmentThiswas proven in a demonstrator as part of the BMBF joint project "Generative production of efficient piezo-MEMS for microactuators (GENERATOR)".

The individual loudspeaker elements are then separated and integrated into an electronic environmentThiswas proven in a demonstrator as part of the BMBF joint project "Generative production of efficient piezo-MEMS for microactuators (GENERATOR)".

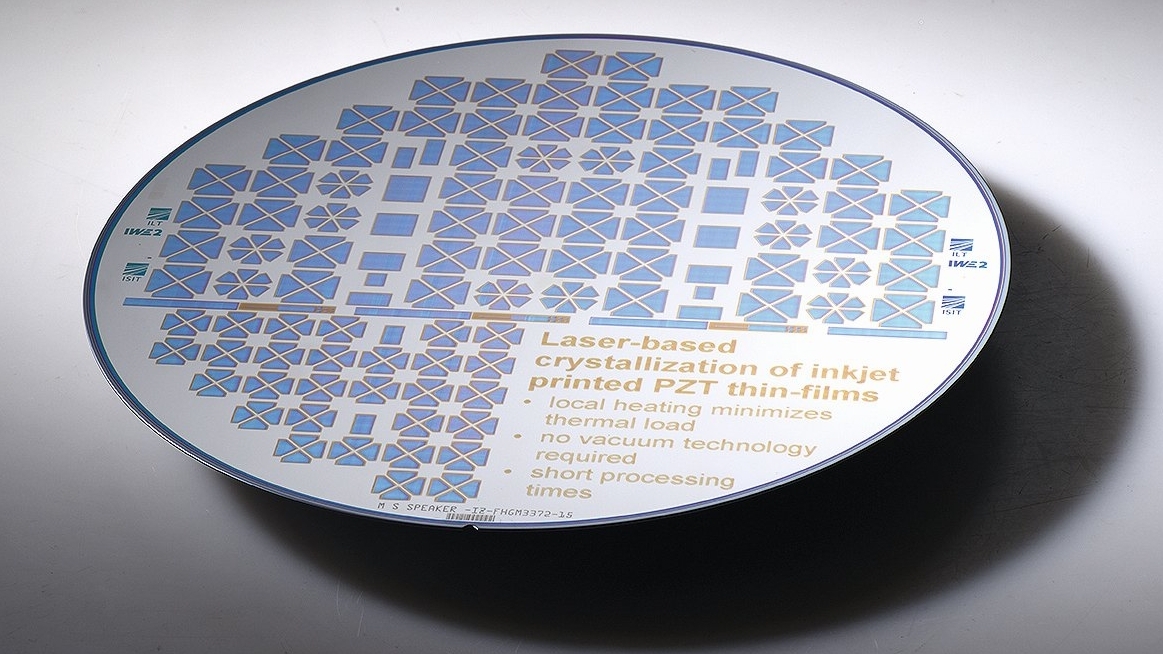

The thin films usually consist of lead zirconate titanate (PZT). Until now, time-consuming conventional vacuum and mask-based manufacturing methods have been used in the production of piezo MEMS. As part of the GENERATOR project, Fraunhofer ILT, together with Fraunhofer ISIT and IWE2 at RWTH Aachen University, has therefore developed a low-cost alternative process combination of digital inkjet printing and laser crystallization: PZT special ink is applied to 8" silicon wafers, followed by crystallization using laser radiation at local temperatures of over 700 °C. The PZT special ink is then applied to the wafers. A multi-layer actuator with a total layer thickness of 2 to 3 µm is built up from up to 30 PZT layers that are only a few nanometers thick. When an alternating voltage is applied to this multi-material stack, the PZT layers deform in fractions of a second, causing the stack to vibrate. The process is particularly suitable for small and medium-sized enterprises (SMEs), as the investment in the system technology is significantly cheaper compared to conventional technology. So far, the process has been used for coating silicon substrates, but other substrates such as ultra-thin glass are also conceivable.