As the energy industry switches to H2 technologies on a broad scale, the "too much" energy produced in areas with an energy surplus can be used to produce hydrogen using electrolysis. PVD coating technology offers solutions for the production of suitable biopolar plates for electrolyzers and fuel cells.

In recent decades, a large number of different types and designs of fuel cells and electrolysers have been developed and tested [1]. PEMECs (proton exchange membrane electrolyzers) and PEMFCs (proton exchange membrane fuel cells) have various advantages in terms of efficiency and handling. During operation, ultrapure water is split into oxygen and hydrogen in PEMECs by an external power supply - in PEMFCs, oxygen and hydrogen are converted into ultrapure water and electricity is generated.

Bipolar plates as basic elements of PEMECs and PEMFCs

The basic structure of these two elements is very similar: so-called bipolar plates (BiPs) are pressed together alternately with seals and membranes in a stack of several hundred pieces. The dimensions of the plates depend on the application and typically range from 500 mm x 150 mm (automotive fuel cells) to 1500 mm x 1500 mm (industrial electrolyzers).

In the past, titanium sheet was often used as the base material for these plates, which were usually produced in small batches. After forming, cutting, welding and leak testing, finished BiPs are produced from two individual sheets (thickness ~ 0.1 mm), which are then stacked. With a growing annual demand of up to several hundred million BiPs for fuel cells and especially electrolysers in the medium term, many manufacturers are endeavoring to replace the base material titanium with more cost-effective stainless steel sheet as they scale up production. However, in addition to the desired advantage of reducing costs by switching to cheaper stainless steel, there is also a disadvantage in terms of the service life of the plates:

In both PEMECs and PEMFCs, chemical processes take place during operation that attack the surface of the materials used in the medium and long term and lead to corrosion. Various studies show that when using BiPs made of pure stainless steel, the internal corrosion processes make it difficult to achieve the service life of at least 10,000 operating hours targeted for passenger car fuel cells, for example. In the case of fuel cells for heavy-duty applications or for electrolysers in continuous operation, even much longer lifetimes must be achieved. Efforts are therefore being made to find ways to protect the plates from this corrosion (target value of the corrosion current < 1 µA/cm2 according to DoE [2]) without having to accept losses in the required high conductivity (target value Interface Contact Resistance, ICR < 10 mΩ-cm2 according to DoE [2]) of the BiPs.

PVD coating technology, which has been used for decades for a wide range of applications, offers a solution to this problem. By applying suitable coatings to both outer sides of the bipolar plates, their corrosion behavior under long-term operation and thus their service life can be significantly optimized. At the same time, there is no loss of conductivity, but even improvements towards a desired high conductivity value. PVT Plasma und Vakuum Technik from Bensheim offers coating solutions for precisely this range of applications and requirements.

35 years of experience in vacuum coating

PVT Plasma und Vakuum Technik, with around 200 employees worldwide and its headquarters in Bensheim near Frankfurt am Main, has been operating in the field of ion and plasma-supported PVD coating of tools and components for more than 35 years. The company comprises the business areas of plant engineering with the construction of standardized series systems and customer-specific coating solutions, research and development for the development of new coating concepts and coating processes as well as services such as contract coating and technical consulting.

Thanks to decades of expertise in PVD technologies such as arc evaporation, magnetron sputtering and plasma nitriding as well as PE-CVD (plasma-enhanced chemical vapor deposition), the coating technology that best meets the customer's requirements from laboratory scale to industrial implementation is used. At the customer's request, PVT supports the realization of complete coating centers with the necessary coating technology, supplemented by equipment for pre- and post-treatment and cleaning of tools and components, as well as the necessary equipment for in-process and final quality control. Assistance and training in the commissioning of the complete processing chain make it possible to offer the customer complete turnkey coating solutions.

In recent years, PVT has developed systems for the large-scale industrial PVD coating of bipolar plates for electrolysers and fuel cells.

High-throughput in-line systems for coating BiPs

Although the coatings that are applied to the bipolar plates are very thin, this is a decisive cost factor in the production of these plates. For a plate with a size of around 750 cm2, the cost of coating should be well below 1 euro/plate.

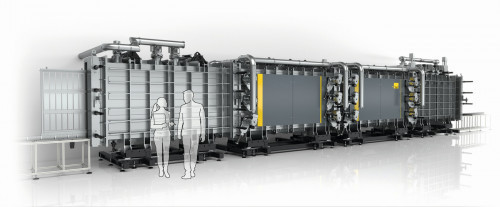

Fig. 1: High-throughput in-line system for PVD coating of bipolar plates for fuel cells and electrolysers with a maximum coating area of up to 3.5 m x 1.5 m

Fig. 1: High-throughput in-line system for PVD coating of bipolar plates for fuel cells and electrolysers with a maximum coating area of up to 3.5 m x 1.5 m

Simultaneous coating of both sides of a BiP requires a highly productive coating process and reliable coating technology. As already mentioned, several hundred individual BiPs are combined in a stack to build a fuel cell or an electrolyzer. It is obvious that with the extremely high quantities of BiPs required for the construction of tens of thousands of fuel cells or electrolysers, the use of batch coating systems, which are usually used in tool and component coating, is uneconomical and not expedient in terms of productivity.

To maximize productivity, coating systems should work in continuous throughput operation. As a result, only so-called in-line systems, in which substrates are coated on both sides at high throughput and without rotation, are suitable for such mass production. In contrast to batch systems, these are multi-chamber systems in which the substrates are transported from chamber to chamber (Fig. 1). The chambers are separated by large transfer valves, allowing various defined process steps to run separately in terms of space and time. This design enables a clean environment with constant vacuum and process conditions.

Magnetron sputtering, arc evaporation or PE-CVD can be used as the coating process, depending on the customer's wishes and the requirements for coating the BiPs. Depending on the coating process used, the BiPs to be coated can move continuously past the coating sources in translation, remain completely stationary or move back and forth (wobble) in clearly defined cycles.

Using the i-L 4.3500 (Fig. 2) developed by PVT, around 5,000,000 BiPs for fuel cells with dimensions of 500 mm x 150 mm can be coated on both sides per year at a highly industrial throughput, with constant process conditions and therefore consistent quality.

Fig. 2: In-line system i-L 4.3500 for PVD coating of up to 5 million fuel cell BiPs per year

Fig. 2: In-line system i-L 4.3500 for PVD coating of up to 5 million fuel cell BiPs per year

The system is designed as a combination of four chamber-shaped individual modules, allowing several positions of BiPs to be fed in simultaneously (atmosphere -> vacuum), coated under constant vacuum conditions and finally discharged again (vacuum -> atmosphere).

The system's internal transport system, which moves the plates to be coated through the individual chambers with the various process steps, can accommodate substrates up to 3.5 x 1.5 m in size. Therefore, in addition to a large number of fuel cell BiPs, several of the significantly larger BiPs for electrolysers can also be coated at the same time.

The coating costs per panel (in relation to the fuel cell BiPs) are typically well below EUR 1.00 and can be significantly lower depending on the process and coating materials used.

Coating systems

Over the past decades of fuel cell and electrolyser research, a wide variety of coatings and coating systems have been developed and tested worldwide. When transferring these coating systems from the laboratory with tests on very small and small series to industrial scale with consistent and high-quality series production, the motto "as good as possible, as cheap as possible" often applies.

Depending on the planned application and the respective operating modes, the use of different shift systems is recommended, particularly for economic reasons. For example, the continuous operation of an electrolyser with a high but constant current load obviously places completely different demands on the corrosion resistance of the BiPs used than use in the automotive sector with continuously changing loads such as when accelerating a car or truck, cold start conditions, idling, etc. In other words, under what technical and economic conditions should the service life of the BiPs be optimized and to what extent?

The most common coating systems to date can be roughly divided into three families:

In the first case, coating the BiPs with pure precious metals can prevent corrosion and at the same time optimize conductivity. Often, for example, a pure gold layer with thicknesses of up to 1 µm is applied to the plates. It is easy to calculate that the target price of < 1 euro per plate cannot be achieved with such layer thicknesses due to the material price alone. For this reason, pure precious metal coatings are currently only used in areas where economic considerations play a secondary role. This is the case, for example, with fuel cells in the aerospace industry, where requirements for service life and operational safety clearly outweigh the pure manufacturing costs [3, 4].

The second family consists of metal-nitride layers in combination with a thin top layer of precious metals. For example, a layer of titanium nitride (TiN) around 500 nm thick ensures that the hydrogen flowing along the BiPs cannot diffuse through the stainless steel sheet. At the same time, the plate is given long-lasting corrosion protection against the chemical processes taking place in the respective cells. The conductivity of the plate is also optimized by a very thin, only a few nanometers and thus economically favorable top layer made of a precious metal such as gold, and the required target values (ICR < 10 mΩ-cm2) are achieved or exceeded. PVT cooperates with the company evm repenning in the field of these metal-nitric layers. Thanks to many years of cooperation with well-known international manufacturers of fuel cell BiPs for automotive applications, evm repenning has references on the application of these coating systems in years of series use under real conditions [5, 6].

The third group consists of carbon-based coatings. In the simplest case, the BiP is provided with a layer of DLC (diamond-like carbon), which both minimizes corrosion and maximizes conductivity. Due to the low price of the base material (graphite) and the non-use of precious metals, the costs per coating are the lowest in this case. However, there is still a lack of clearly reliable long-term studies for this family of coatings to determine the extent to which the lifetimes known from metal-nitric coatings can be achieved under long-term operation and under real conditions. PVT is also working with proven experts in this field: the company N4E from Madrid [7].

Interested readers can take a look at the results and comparative measurements of the coatings mentioned here on the company website [8].

Outlook

In the meantime, the first i-L 4.3500 has been shipped to a Chinese customer and will go into operation in the next few months. In the production facility there, mass-produced BiPs for fuel cells will be coated and then installed in fuel cells for passenger cars.

An i-L 3.5000 continuous line is currently under construction. In contrast to the i-L 4.3500, this is a 3-chamber system in which substrates with a maximum size of 1 m x 1 m can be coated. The system will remain in-house at PVT as a demo system so that various coating concepts can be evaluated on behalf of customers. This system will be available for contract coating services from mid-2023: Customers will then be able to commission the coating of their BiPs in small batches before procuring their own industrial high-throughput system and have BiPs coated with various coating systems in order to subsequently determine the best and most economical coating for their specific application.

In this way, it is possible to determine which coating system and which system design are ideally tailored to the customer's specific requirements before purchasing their own high-throughput system.

Literature

[1] Fuel Cells - Fundamentals and Applications, FUEL CELLS 2001, 1, No. 1, L. Carrette, K. A. Friedrich and U. Stimming

[2] DOE Technical Targets for Polymer Electrolyte Membrane Fuel Cell Components | Department of Energy, www.energy.gov/eere/fuelcells/doe-technical-targets-polymer-electrolyte-membrane-fuel-cell-components

[3] Session on Fuel Cell Batteries - A Status Report Hydrogen-Oxygen (Air) Systems APOLLO FUEL CELL SYSTEM, Proceeding 19th Annual Power Source Conference, 1965, C. C. Morrill, United Aircraft Corporation

[4] Spacecraft Power Systems, 2004, Mukund R. Patel

[5] Patent specification EP 3 665 314 B1, W O 2019/029762, Coating and layer system, as well as bipolar plate, fuel cell and electrolyzer, 2018

[6] Patent specification WO 01/78175 A1, METAL BIPOLAR PLATE, 2001

[7] The influence of positive pulses on HiPIMS deposition of hard DLC coatings, Surface and Coatings Technology, Volume 358, 25 January 2019, Pages 43-49,

[8] Website PVT Plasma und Vakuum Technik, www.pvtvacuum.de