Cromatipic® coating proves itself as a fully industrialized chrome coating technology for plastic parts, completely without process emissions, i.e. REACh compliant for 2024 and beyond.

Thecoating system is based on UV lacquer and PVD coating and meets the most stringent industrial test criteria. Additional decorative and functional features create new attractive user benefits. Hauzer has been demonstrating the industrial maturity and expertise of Cromatipic® technology with a large coating plant in operation since 2017.

REACh Regulation 1907/2006 created the need to develop chrome coating processes for plastic components that meet the high requirements of the automotive industry but do not require hexavalent chromium substances. Hauzer has developed the Cromatipic® technology to provide a fully viable successor technology for the chrome plating of plastic parts.

The REACh Committee of the European Chemical Agency (ECHA) granted companies using chromium trioxide substances (CrO3) for electrodeposition on plastics a maximum of 7 years to review the availability of safe alternatives or, if possible, to replace the substance earlier. After the sunset date of Sept. 21, 2017, the authorization to use hexavalent chromium substances will expire in about 4 years, on Sept. 21, 2024.

The rapidly approaching expiry triggers the need for the qualification of successor technologies for the chrome plating of plastic parts.

Cromatipic® is a two-layer system consisting of UV lacquer and a PVD chrome coating, which does not require any chemicals containing chrome. It is a fully operational process that meets demanding test requirements. Cromatipic® is an industrialized technology which is continuously applied to automotive components and there are numerous passed validation processes of series applications in the automotive industry. At the same time, the cost efficiency is in line with current market prices for the chrome plating of plastic parts.

Cromatipic® not only complies with the REACh regulation, but is also a true zero-emission process. Both parts of the coating system, the UV coating and the PVD process, do not emit any environmental emissions. The coating process uses 100% solvent-free UV coating that does not contain any VOCs (volatile organic compounds). Conventional solvent-based paints require a downstream regenerative thermal oxidation (RTO) process to burn off harmful air pollutants. Such post-combustion processes are not necessary when using Cromatipic® technology UV coatings - which complies with local and international regulations. It is therefore easy to obtain a plant approval for a Cromatipic® system.

Automotive test specifications

Being a qualified future chrome coating technology for plastic parts means meeting the most stringent automotive test conditions. The gloss variant "Cromatipic® bright", was developed to meet the TL-226 and TL-528 standards, VW's test requirements for painted interior and exterior parts. For example, the hydrolysis test is part of TL-226 in which the coating is subjected to test conditions of 72h at

90 °C and 95 % relative humidity without any change in appearance, adhesion or scratch resistance. Another passed test from TL-226 is the 2000 stroke crock meter test.

Cost Efficiency

Cromatipic® is designed to be the number one successor technology for the electroplating of plastics on a large scale. This also applies to the cost aspect. Hauzer's Cromatipic® coating plant offers pricing that is common for CrIII electroplating. The facility near Barcelona is fully automated and set up for 3-shift operation. Customers can outsource contract plating there.

The coating line has sufficient capacity and is designed for part lengths of up to 1500 mm. Three-dimensional parts can be coated up to a maximum cross-sectional diameter of 200 mm. The process includes both stationary and continuous steps and allows part rotation or non-rotating positioning of substrates.

The color of the chrome layer is of interest to automotive designers. Cromatipic® coatings provide high process stability and high color fidelity, reliably delivering the same color from batch to batch. The color has been approved by automotive OEMs for numerous applications.

Additional decorative and functional features

Metallic colors can also be deposited that are clearly different from the chrome color. Shades of gray, anthracite, brown, brass, gold and black can be deposited using downstream PVD processes. The "gloss" or "matt" option is achieved by using various UV coatings.

Cromatipic® technology opens up a wide range of possibilities for designers. A new coating variant allows backlighting of coated surfaces. Parts can be used either as a light source - with backlighting - or as a decorative, non-backlit element. The lighting effect can be displayed as a line or symbol, or over the entire surface of the part.

The coating process is similar to the Cromatipic® coating on plastic. The luminous effect is achieved by using transparent plastic and UV lacquer as well as a semi-transparent chrome layer. The degree of translucency can be adjusted by the parameters of the PVD chrome coating process. Letters or symbols are applied using a laser etching process. The Cromatipic® translucent variant can be used as decorative light in the vehicle interior or for functional light in the exterior, such as on mirror housings with blinker function.

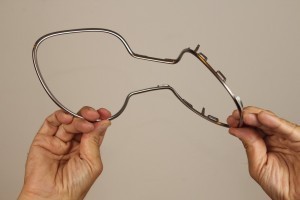

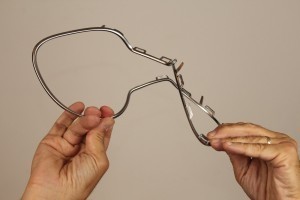

Cromatipic® also offers unprecedented geometric flexibility for coated parts. While galvanized frames - if they are delicate or thin-walled - can break during assembly, the paint-based Cromatipic® coating is highly flexible and does not break during assembly, which eliminates rejects late in the value chain.

Plant construction

With the coating plant near Barcelona, Hauzer is demonstrating the technical and commercial feasibility of Cromatipic® technology. In addition to operating the plant

Hauzer also offers complete turnkey coating systems. The engineers at Hauzer's headquarters in the Netherlands offer fully automated Cromatipic® coating lines, includingCO2 cleaning, UV coating and curing, PVD coating in a Hauzer Metalliner®, an in-line PVD system. The scope of delivery of a turnkey system is supplemented by all system components for the peripheral processes, such as transport system, paint supply, robot systems, ultra-pure air supply, power and paint supplies as well as racks, rack cleaning and more.

As a global PVD system manufacturer, Hauzer can use its service organization to ensure maintenance and servicing for the Cromatipic® system technology.

Hauzer is always ready to receive interested customers at its site near Barcelona who would like to find out more and visit the Cromatipic® coating process.

Cromatipic® proves to be a fully industrialized PVD chrome plating technology for plastics components, with zero process emissions, compliant with REACh for the year past 2024 and beyond.

The coating system is based on UV-lacquer and PVD-coating which complies with the most challenging industrial test requirements. Added decorative and functional features open new and attractive user benefits. With a large coating line in operation since 2017, Hauzer proves the mature and industrialized capability of the Cromatipic® technology.

The REACh directive 1907/2006 has brought about the need to develop chrome coating processes for plastics components that fulfill high needs of the automotive industry, but work without hexavalent chrome substances. Hauzer developed Cromatipic® to be a fully capable successor technology for chrome plating on plastics.

The REACh Committee of the European Chemicals Agency (ECHA) decided to allow companies using chromium trioxide (CrO3) substances in electroplating on plastic parts a maximum of 7 years to reassess the availability of safer alternatives or substitute the substance earlier when possible.

With the sunset date having passed on 21. Sept 2017, the authorization to use of hexavalent chrome solutions will therefore terminate in four years from now, on 21. Sept 2024.

The rapidly/shortly approaching date of the termination now triggers the need for the qualification of succeeding technologies for chrome plating on plastics.

Cromatipic® is a dual layer made of UV-lacquer and PVD chrome coating, completely free of chromium chemistry. It is a fully capable process that complies with challenging testing standards. Cromatipic® is an industrialized technology that is applied on automotive components on an ongoing basis. It has achieved numerous validation processes in long term automotive applications. At the same time, the cost efficiency is compliant with current market pricing for chrome plating on plastics parts.

Cromatipic® not only complies with REACh, but is a real zero emission process. Both Cromatipic® sub-layers, the UV-lacquer coating and the PVD process do not produce environmental emissions. The PVD chrome coating is performed under high vacuum, which does not emit any waste substances. And the lacquering process is using a solvent-free paint (100% solid content) that has no VOCs. Old solvent-paint technologies needed an added regenerative thermal oxidization (RTO) process to destroy hazardous air pollutants (HAPs) and volatile organic compounds (VOCs). Such added burning off process is not needed with lacquer used in Cromatipic® technology - which complies with local and international environment regulations about VOCs emission. Therefore, attaining operational approval for a Cromatipic® coating line is easy.

Automotive test specifications

Being a qualified future chrome plating technology for plastic parts, means to pass the most challenging automotive test conditions. "Cromatipic® bright" was developed to be compliant with TL-226 and TL-528, the lacquer/plating test specifications of VW for interior and exterior applications. For example, part of TL-226 is the hydrolysis test where the coating passes test conditions of 72h of 90 °C at 95 % relative humidity, without change of appearance or change in adhesion and scratch resistance. Another fulfilled test under TL226 is the crock meter test, conducted with 2000 strokes.

Cost efficiency

Cromatipic® is developed to be utilized in large scale - as the number one successor of electroplating in the chrome plating on plastics. This also relates to the cost viewpoint. Hauzer's facility for Cromatipic® coating service offers coating pricing that typically is in line with the coating prices of Cr(III) based electroplating. The facility near Barcelona is fully automated and capable of 3-shift operation. Customers can outsource coating service or - in combination - can source injection molded parts with Cromatipic® coating.

The line is set up for large capacity and can be used for large parts, up to 1500mm length. 3-dimensional parts can be coated up to a largest cross section diameter of 200mm. The process that includes stationary and continuous coating process steps allows rotation and non-rotational positioning of substrates.

The chrome color is of interest for automotive designers. Cromatipic® coatings perform high process related color uniformity which is reliable and guarantees high repeatability from batch to batch. Its color was approved for numerous automotive applications by leading OEMs

Added decorative and functional features

Beyond chrome color coatings, one can also deposit metallic colors that are clearly differentiated from chrome color. Dark grey, anthracite, brown, golden/brass, and black coatings can be deposited with downstream PVD processes. Gloss options include "bright" or "matte" are realized by using different UV-lacquers.

Cromatipic® technology also opens up new possibilities for the automotive designer. One of the new versions of Cromatipic® coating provides the option of illumination effect of chrome plated areas. By choice, components can work as a light source when backlit, or as a decorative chrome component when not backlit. The illumination can be controlled to be on selective areas such as symbols or lines, or on the entirety of the component

The coating process works similar to the Cromatipic® coating on plastics. The illumination feature is realized by using translucent plastics material, translucent UV lacquer and a semi translucent chromium layer. The degree of light translucency can be determined by the parameters of the PVD chrome coating process. Characters or symbols are implemented through a laser etching process. The feature of Cromatipic® translucent can be used in car interior to display decorative light or in the exterior for light indicators such as on chrome mirror housings.

Cromatipic® also offers previously unseen geometric flexibility of finished parts. While electroplated thin and fragile frames are often subject to breakage during the final application assembly, the lacquer based Cromatipic® is extremely flexible, will not likely break during assembly which avoids scrap at a late section of the value chain.

Equipment offering

With the coating facility near Barcelona, Hauzer demonstrates the technical and commercial feasibility of Cromatipic® technology. But beyond the operation of the coating facility, Hauzer offers complete turn key coating lines. The engineers at the Hauzer headquarters in the Netherlands offer Cromatipic® coating lines as a fully automated system withCO2 cleaning, UV-lacquering, UV-curing, PVD coating in a Metalliner®; an in-line PVD coating system. The turn key scope of delivery comprises also equipment for the peripheral processes such as conveyor, handling robots, clean air supply, power supplies, lacquer supply, fixtures, cleaning unit for of fixtures and more. Being a PVD equipment manufacturer with a global footprint, Hauzer can utilize its global service organization to service Cromatipic® equipment.

Hauzer is always set up to welcome interested customers in their coating facility near Barcelona to get more information and to view the Cromatipic® coating process.

Literature

[1] Auto.Int. world magazine, issue 2017, page 53

[2] ATS, 2018, page 16

[3] Auto.Int.World magazine, issue 2018, Oct., page 63

[4] Auto.Int.World magazine, issue 2019, May, page 79

REFERENCES

[1] Auto.Int.World magazine, issue 2017, page 53

[2] ATS, 2018, page 16

[3] Auto.Int.World magazine, issue 2018, Oct., page 63

[4] Auto.Int.World magazine, issue 2019, May, page 79