As part of the "Press Breakfast", institutes of the Fraunhofer-Gesellschaft regularly present current research highlights on site and via livestream.

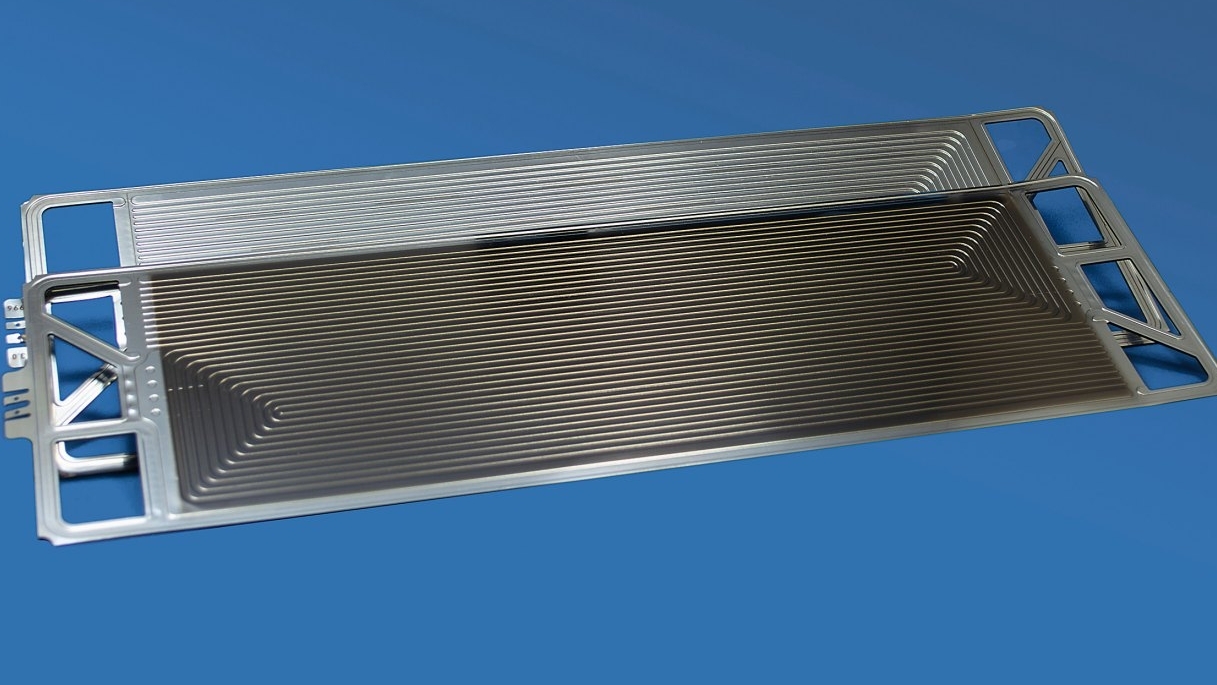

Daimler's bipolar plate is provided with a carbon layer (lower half), which reduces contact resistance and at the same time increases corrosion resistance

At the sixth edition of #FEMoS on September 29, 2020, participants learned more about radar sensors for headlights and the latest results in the fields of energy research and hydrogen technology (information at http://s.fhg.de/iws-youtube).

The Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP started with the topic of developing radar sensors for integration into innovative vehicle headlights.

Due to the use of modern driver assistance systems, the use of radar technology in the automotive sector is an indispensable technological component. The installation of a constantly growing number of sensors in combination with the limited availability of exposed measuring points results in the problem that there is hardly any installation space available for the installation of sensors. Together with partners, the FEP is developing radar sensors that can be integrated into the headlights of a car in the "RadarGlass" project (FKZ: 03VP03202 FEP) funded by the German Federal Ministry of Education and Research BMBF.

"Graphite instead of gold" says the Fraunhofer Institute for Material and Beam Technology IWS and presents thin layers for better hydrogen cars.

Hydrogen-powered fuel cell cars are still rare and expensive. In addition to efficiency problems, this is also due to a core component: gold-coated bipolar plates (BiP) in fuel cells are expensive and complex to manufacture. The Fraunhofer Institute for Material and Beam Technology IWS in Dresden and Dortmund, the German automotive group Daimler and the Finnish steel company Outokumpu Nirosta have now developed an inexpensive alternative for rapid mass production. Instead of gold, they coat the bipolar plates with a wafer-thin layer of carbon.

"Green" hydrogen as an energy source:

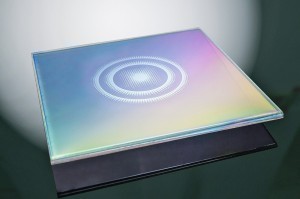

Magnetron-sputtered TCO coating with laser-structured antenna structures Two projects dealing with the production of the "green" energy carrier hydrogen from renewable energies and an exemplary application were also presented:

Magnetron-sputtered TCO coating with laser-structured antenna structures Two projects dealing with the production of the "green" energy carrier hydrogen from renewable energies and an exemplary application were also presented:

Catalyst-coated nickel foam electrodes for water electrolysis come from the Fraunhofer Institute for Manufacturing Technology and Advanced Materials IFAM. Green hydrogen for use inCO2-free steel production is the subject of work at the Fraunhofer Institute for Ceramic Technologies and Systems IKTS.

The next event: The press breakfast takes place on campus once a year, so the next press breakfast will be in September next year. A fixed date is being worked out and has not yet been set.