The Fraunhofer IWS has developed LIGHTblast laser technology to clean and structure surfaces particularly quickly and in an environmentally friendly manner. Sandblasting was yesterday. Laser beams can be used to clean and structure surfaces more precisely, cheaply and environmentally friendly than conventional systems.

The process can be automated more easily with positive effects on quality, process control and occupational safety. The system also works much more precisely than a sandblasting system, as a laser beam with a diameter of less than 50 micrometers replaces a particle stream several centimeters wide.

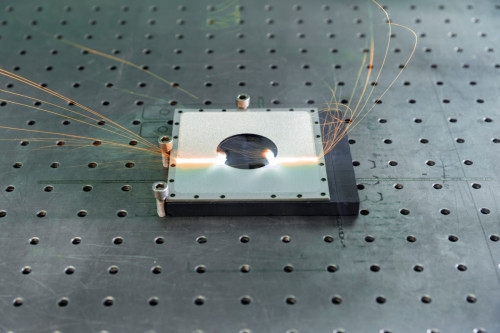

The laser blasting system precisely processes only the desired surfaces, using neither sand nor masking material and thus saving on hazardous waste and adhesive tape waste. (Image: © René Jungnickel/Fraunhofer IWS)

The laser blasting system precisely processes only the desired surfaces, using neither sand nor masking material and thus saving on hazardous waste and adhesive tape waste. (Image: © René Jungnickel/Fraunhofer IWS)

Many preparation and post-processing steps are also eliminated: light-based processing requires no chemicals for cleaning. The laser blasting system precisely processes only the desired surfaces, using neither sand nor material for masking and thus saving on hazardous waste and adhesive tape waste. The laser beam vaporizes parts of the surface, the expanding vapour tears away solid components and also achieves a defined roughness. In general, the new method can be used wherever components need to be cleaned, pre-structured or roughened in order to subsequently coat them. Further development steps are planned for this.