The GFE - Gesellschaft für Fertigungstechnik und Entwicklung Schmalkalden e. V. is a business-oriented research institution in the legal form of a registered association. It offers complete solutions for all aspects of (machining) tools. Its roots lie in the traditional tool industry. Practical relevance and many years of experience are combined with knowledge from basic and applied research. Together with its customers, it develops product and technology solutions as key factors of entrepreneurial success. Sophisticated, visionary and innovative in the solution of development tasks, at the same time practical and demand-oriented in implementation, GFE is the right partner - not only for medium-sized companies!

GFE's core competencies and range of services

GFE's core competencies in research, development and services include the areas of production technology, tool technology, machining technologies, coating technology, measurement technology and quality assurance. The entire process is always taken into account, processes, products and systems are developed, optimized and implemented from the initial idea to small series production (Fig. 1). The focus is on the tool and the machining technology.

The range of research and services includes

- Development and evaluation of precision tools

- Optimization of effective machining technologies

- Machining of new materials

- Development and evaluation of wear protection and hard coatings

- Calculation, testing and measurement methods for tools, components and coating composites

- Design and simulation.

Coating technology

At the GFE Schmalkalden coating center, hard coatings with high wear and temperature resistance are developed, implemented and evaluated. Deposition is mainly carried out using the arc PVD process. Diamond-like coatings (DLC) can also be deposited using plasma-assisted CVD (PE-CVD). With the new system technology available, it is also possible to deposit coatings using magnetron sputtering and HiPIMS. In addition to standard hard material coatings (e.g. TiN, TiCN, TiAIN or AITiN), high-performance coatings such as nanocomposite and multifunctional coatings as well as newly developed oxynitride coatings and

boron-containing coatings for use at high temperatures, DLC coatings and, in particular, tetrahedral amorphous carbon coatings (ta-C) for low friction as well as adhesion-optimized coatings for base materials that are difficult to coat are evidence of our expertise in this area.

Possible applications and areas of use

Potential areas of application and objectives of hard material coating using the PVD process can be found in many industrial areas of production technology, mechanical engineering, automotive engineering and plastics technology. The main areas of application are

- Machining (Fig. 2)

- Sheet metal forming and punching

- Guides, sliding elements, machine components

- Plastics processing

Fig. 1: GFE portfolio

Fig. 1: GFE portfolio

Fig. 2: Selection of different PVD-coated cutting tools

Fig. 2: Selection of different PVD-coated cutting tools

| Machining | Sheet metal forming and punching | Guides, sliding elements, machine components | Plastics processing |

| Longer service life Wear protection High hardness Less friction Dry machining Reduced built-up edge formation Thermal insulation |

Reduced friction Longer tool life Reduced tendency to weld Reduced use of lubricants Reduced forming forces |

Reduced friction Dry running Wear protection Longer service life Decoration |

Improved demolding Reduced adhesion tendency Dry running Improved surface quality of manufactured parts Shorter cycle times Scratch protection |

Table 1: Possible applications and advantages of hard coatings

With a coating thickness of usually 2-3 µm, the coatings have a very wide range of applications, from simple wear protection of tools to the optical design of components. When coating tools, parts and machine components, the main objectives are improved wear resistance and a reduced coefficient of friction. In addition, hard coatings offer further application possibilities and advantages in the areas of machining, sheet metal forming, machine components and plastics processing (Table 1).

Facilities

The equipment at GFE's coating center for the deposition of PVD coatings has been continuously expanded since 2002. Various coating technologies (p 80, p 300, p 211, p 411) from Platit AG, Switzerland, are used here. The maximum component size that can be coated is approximately Æ 500 mm × height 500 mm.

In addition to the production of standard PVD hard coatings, the available coating systems have special features with regard to the available technology and coating materials. Of importance here is the deposition of extremely hard nanocomposite coatings, very temperature-resistant oxynitride coating systems and friction-reduced DLC coatings.

The latest coating systems from GFE (p 211, p 411, Fig. 3) also have the following special features:

- p 211: filtered arc (for droplet reduction), very hard ta-C coatings

- p 411: magnetron sputtering, pulsed sputtering (pPIMS), boron-containing coatings.

Coating systems

GFE offers both conventional PVD coatings and application-specific coatings as a service. Deposition usually takes place on metallic materials, but other substrates, e.g. ceramic substrates, are also possible on request. For deposition by means of PVD coating, the coating temperatures in the normal process are 400-480 °C; for individual special coatings, coating temperatures of 120-220 °C are possible.

In cooperation with the industrial partners, the selection and development of the most suitable coatings for the respective application and the deposition of the coatings on customer components are carried out. The coating recommendations are developed on the basis of our own investigations and the experience of the manufacturer of the existing coating systems. The following coating systems can be

be deposited with the available system technology:

- Conventional coatings: TiN, TiCN, TiAlCN,

TiAlN, CrN, ZrN, AlTiN, AlTiCrN - Nanostructured coatings: nACo, nACRo (nanocomposites) based on AlTiN or AlCrN in a Si3N4 matrix

- Combination of conventional and nanostructured coatings, combination of different functions in a multifunctional coating system

- Oxygen-containing layers: CrTiON, ZrON, AlCrON (patent application: DE 10 2010 052 687 A1)

- Diamond-like layers (DLC): a-C:H:Me; a-C:H:Si; ta-C

- Boron-containing layers: TiB2, AlCrTiN/BN

- Adhesion-optimized coatings: Combination of additional adhesion promoter layers with different layer systems; patents: EN 10 2010 006 267,

DE 10 2008 015 013 A1

Fig. 3: Latest system technology GFE (Platit AG): p 211 (top), p 411 (bottom)

Fig. 3: Latest system technology GFE (Platit AG): p 211 (top), p 411 (bottom)

Layer development

GFE not only works in the field of coating technology, but also considers the entire production process when coating, taking into account the use of tools, stresses, processes, technologies and requirement profiles. Increasingly, complex PVD coatings and coating combinations such as multiple/multilayer coatings, gradient coatings, nanocomposite coatings, oxygen-containing coatings, diamond-like coatings or boron-containing coatings on different substrate materials are being used.

We do not simply offer a coating variant, but a functionally sophisticated coating solution that covers all aspects of the machining process and the process chain of coating and coating adhesion.

coating and coating adhesion. Together with industrial partners and research institutes, coatings are developed for various applications and operating conditions based on the respective application and tested in the GFE test field.

The main development priorities are

- Development of coatings with high strength for application temperatures > 1000 °C

- Development of friction-optimized coatings based on diamond-like structures

- Improving coating adhesion when coating difficult-to-coat materials such as CBN, PCD, ceramics

- Coating at deposition temperatures < 150 °C

- Coating developments with customer-specific requirements (e.g. coating thickness > 10 µm, coatings with reduced residual stress, very smooth coatings).

Based on these core topics, coatings and technologies are developed for users in production technology, mechanical engineering, automotive engineering and plastics technology in both basic and application-oriented development projects.

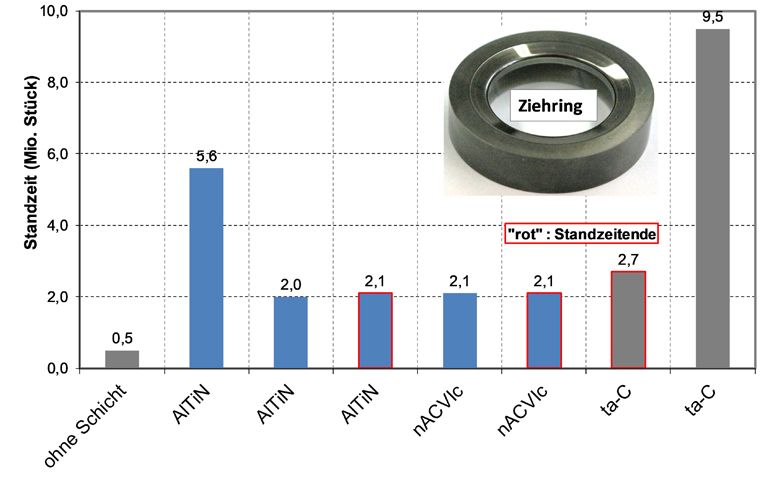

For example, tetrahedral amorphous coatings (ta-C) have a high proportion of diamond-like structures and therefore have a very high hardness and a very low coefficient of friction. For example, in a ZIM project (FKZ: 16KN019723) carried out with the company MALA Verschluss-Systeme GmbH, a significant increase in the tool life of appropriately coated drawing tools was demonstrated during forming by deep drawing (Fig. 4, left). In addition, the use of release agents can be reduced.

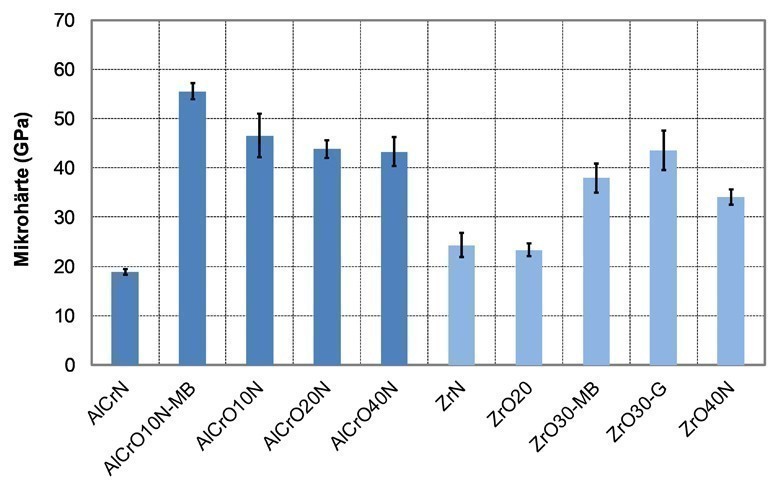

In a project funded by the Thüringer Aufbaubank (FKZ: 2007 WFN 0241), the incorporation of oxygen into a PVD coating composite generated lattice distortions and improved the thermal and mechanical stability of the coatings. The increased hardness of the oxynitride layers (up to 55 GPa) enables improved wear resistance against abrasive wear at a higher application temperature (Fig. 4, right). As a result, the oxygen-containing coatings can be used successfully for machining difficult-to-cut materials (e.g. nickel-based and titanium alloys).

Other successful developments include

Coating of cutting tools with PVD hard coatings:

- Increased tool life

- Positive influence on chip breaking

- Optimization of machining conditions through coordinated coatings

Increased service life of punching and forming tools

- Wear protection, edge protection

- Friction coefficient optimization

- Increased service life

- Wear protection coatings on components

- Wear reduction or prevention of adhesion wear, abrasion wear, physical-chemical wear, cavitation wear, friction wear, etc.

Setting optimum coefficients of friction for mechanically and tribologically stressed parts and machine components

- Reduction of the coefficient of friction of surfaces through diamond-like (DLC) coatings

- Reducing the amount of lubricant used in various machining processes

- Optimization of dry-running properties

Reduction of sticking and other adhesion effects during the processing of plastics

- machining and processing of plastics

- Machining of adhesive materials such as aluminum and titanium

Characterization of coating and surface properties

The coatings can be characterized with regard to their properties using various methods. The following parameters can be analyzed at GFE Schmalkalden:

- Coating thickness (according to DIN EN ISO 26423) and coating structure

- Coating adhesion according to DIN EN ISO 26443, DIN EN ISO 20502 and DIN 4856

- Hardness (HU and HV) according to DIN EN ISO 14577

- Coefficient of friction and wear (ball/disc, ball/pyramid, pin on disc)

- Fracture structure (SEM)

- Chemical composition (EDX)

- Surface structure (optical and tactile)

- Layer stresses (deflection)

- Hard metal analysis: magnetic saturation, coercivity and density according to DIN ISO 3326

- Metallographic examinations in accordance with DIN EN ISO 4499 and DIN ISO 4505

All necessary testing and analysis equipment is available.

Fig. 4: Tool life of ta-C coated deep-drawing tools (top); hardness increase due to oxynitride coatings (bottom)

Fig. 4: Tool life of ta-C coated deep-drawing tools (top); hardness increase due to oxynitride coatings (bottom)

Conclusion

The GFE sees itself as a developer and service provider that works with partners to develop coatings for various key applications and operating conditions and tests them in the GFE test field or at partner companies. The recording and definition of tasks and needs analysis, also on site, includes consulting, coating development, coating pre- and post-treatment, coating diagnostics, decoating and testing. Based on this principle, coatings and technologies are developed for users in the fields of production engineering, mechanical engineering, automotive engineering and plastics technology in both basic and application-oriented development projects.