In times of great challenges and uncertainty in the construction industry, BAU - the world's leading trade fair for architecture, materials and systems - proved to be a beacon of hope for the sector. Despite being shortened by one day, well over 180,000 visitors came to find out about innovations and trends in mid-January 2025. Solar energy is also important for the construction industry, especially innovative technologies such as perovskite solar cells.

The construction and building sector is facing major challenges: Climate change, rising energy prices and stricter regulations require sustainable solutions to reduce the energy requirements of buildings and improve theircarbon footprint. Perovskite solar cells offer great potential for building-integrated photovoltaics, as they are flexible, easy and inexpensive to manufacture and have impressed with enormous advances in efficiency in recent years.

Fraunhofer at BAU

Under the motto "FutureMissionBuilding - safe. sustainable. affordable", the Fraunhofer Building Innovation Alliance presented innovations in the three key transformation areas of construction: sustainability, productivity and resilience. The exhibits were on display in and around a two-storey "Innovation Cube". This symbolized a building and served to demonstrate current intelligent solutions from the building envelope to the interior. Possible applications of thin-film technologies in the construction and building sector were presented, as well as innovative solar cell development technologies based on perovskite and OPV technologies. Other topics included the removal of pollutants from wooden structures using plasma processes and environmentally friendly cement formulations. Fig. 1: Flexible perovskite solar cell test structure (Photo: VTT Technical Research Centre of Finland Ltd)

Fig. 1: Flexible perovskite solar cell test structure (Photo: VTT Technical Research Centre of Finland Ltd)

The Fraunhofer FEP, for example, presented the following topics in the model house:

- Low-E coatings

- Thermochromic coatings

- Antibacterial coatings and surfaces

- Anti-reflective coatings for glass applications

- Coatings for ultra-thin, flexible glass

- Barrier coatings for solar applications

- 3D coatings for tube collectors and zeolite heat accumulators

- Structuring processes for design PV applications

- Production of sustainable building materials through biogenic lime synthesis

- Glass modules with anti-reflective coating

- Reconstruction of historical mirrors using mercury-free thin films

- Innovative coating systems for sustainable photovoltaic solutions in the building sector

The Fraunhofer FEP makes important contributions to the further development of technologies in sheet-to-sheet and roll-to-roll processes. Flexible organic solar cells offer great potential for building integration. As part of the two EU-funded projects "Pearl" and "Booster", researchers are working on new materials and coating technologies to develop components for sustainable, long-lasting solar solutions for the construction and building sector (Fig. 1).

Pearl - Flexible perovskite solar cells for sustainable energy

As part of the EU-funded "Pearl" project, the Fraunhofer FEP is working with international partners to develop the next generation of flexible perovskite solar cells. Over the next few years, the researchers in Dresden want to develop a combination of a permeation barrier and a transparent electrode layer. Such layers already exist. In the project, both products are now to be combined in order to save film material on the one hand and a process step on the other. The challenge is to combine the properties of both components - barrier and electrode - in such a way that they do not interfere with each other. Initial results have already been achieved on the coFlex in-line vacuum coating system for roll-to-roll coating.

Booster - organic photovoltaics for the building sector

The EU-funded "Booster" project focuses on the development of organic photovoltaic modules (OPV), which are particularly suitable for building applications such as building-integrated photovoltaics. They are lightweight and very flexible, which makes them ideal for use on buildings, especially on curved surfaces and in a vertical direction. As part of the project, the Fraunhofer FEP is developing a highly transparent and durable front encapsulation film (frontsheet) that protects the OPV modules from UV radiation and moisture.

Specifically, the researchers want to develop a film substrate that not only offers better protection against environmental pollution through a barrier layer, but also increases transparency. In addition, the project partners in "Booster" are focusing on developing a production concept for the OPV modules that enables efficient coating at low cost. To this end, a roll-to-roll production line is being optimized and work is being done on scaling all materials and processes for such production. At the end of the project, an OPV module including the process technologies should be available that can be used and transferred by future manufacturers of flexible solar cells or other opto-electronic components.

Removing pollutants from wooden structures

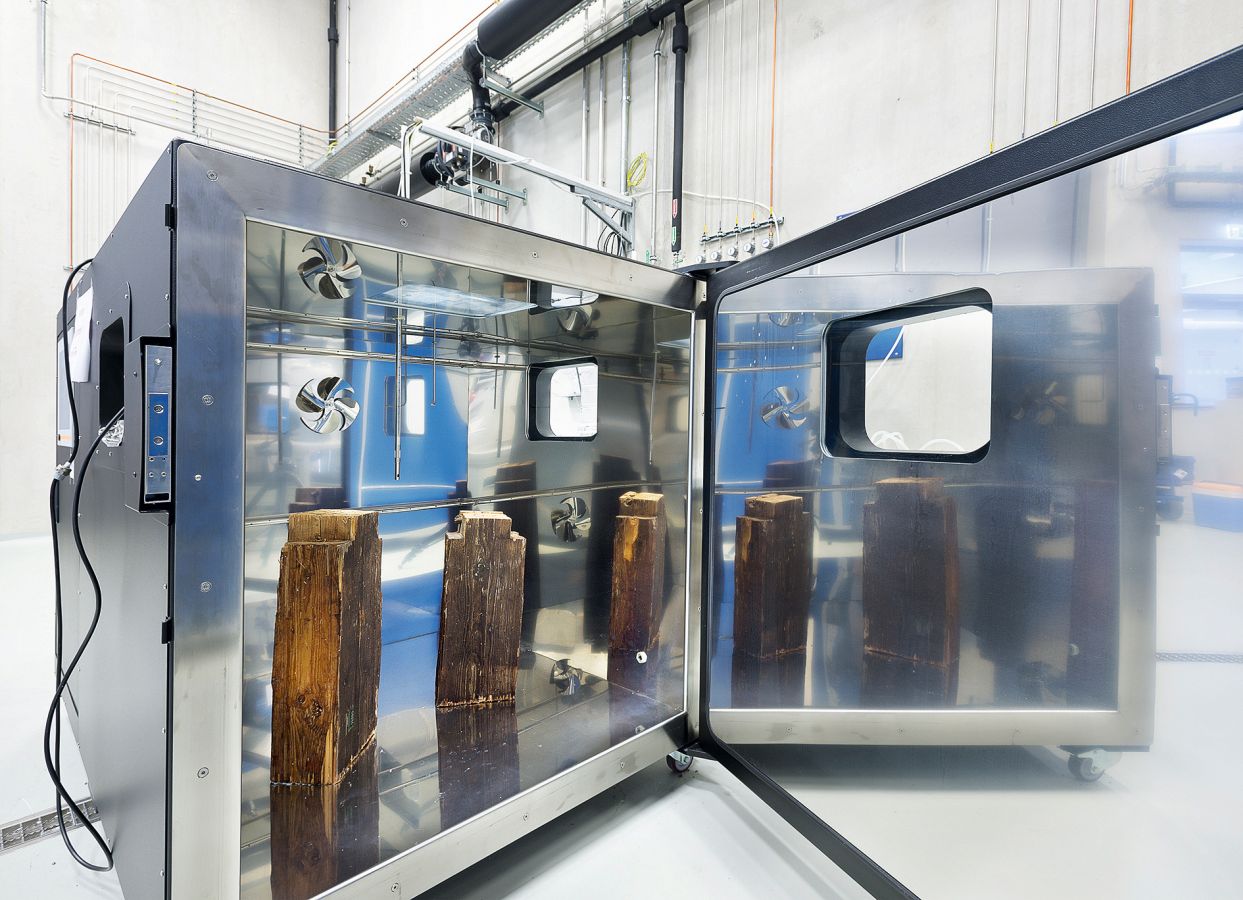

There are around three million buildings in Germany that are contaminated with the toxic wood preservatives lindane and pentachlorophenol (PCP). Even today, contaminated wooden beams, wood paneling and roof trusses pose a health risk. Historic buildings and old buildings are particularly affected. Measures taken to date to minimize contamination are neither sustainable nor cost-effective. In the CycloPlasma project, researchers at the Fraunhofer Institute for Building Physics IBP are developing a new type of process to remove the remaining pollutants from the air and from contaminated wooden structures without leaving any residue, sustainably and without posing any health risks. An innovative adsorber material is combined with plasma technology (Fig. 2).

Fig. 2: Wood contaminated with wood preservatives in a 1 m3 emission test chamber (Photo: Fraunhofer IBP / Bernd Müller)

Fig. 2: Wood contaminated with wood preservatives in a 1 m3 emission test chamber (Photo: Fraunhofer IBP / Bernd Müller)

The researchers use cyclodextrins (CD) as adsorber material, which is applied to the wood like a varnish. They enclose the lindane and PCP in a cavity and encapsulate it completely. The colorless texture does not change the wood structure, does not trigger mold growth, is non-toxic, colorless, biodegradable and washable. The excess pollutants are released into the indoor air and a plasma device, which can be attached to the ceiling for example, absorbs the harmful substances and breaks them down chemically. Electrodes generate a plasma gas through which the air flow with the pollutants is drawn. In addition, activated carbon filters prevent gaseous decomposition products from escaping from the device. The technology is currently being tested in practice with extensive measurement technology in the contaminated attic of the historic Thürlmühle mill, which is located on the grounds of the project partner, the Glentleiten Open-Air Museum.

Environmentally friendly cement formulations

In view of the growing demand for climate-neutral building materials, new manufacturing processes are also being sought in the construction sector. The Fraunhofer FEP is researching innovative electron beam-assisted processes for increased biogenic lime synthesis using phototrophic microorganisms in order to support the decarbonization of the cement industry. In this way, theCO2 footprint of cement formulations can be further reduced in the future and fossil limestone can be gradually replaced as a primary resource (Fig. 3).

Fig. 3: Reamode test facility for modifying organic materials with accelerated electrons (Photo: Fraunhofer FEP, Finn Hoyer)

Fig. 3: Reamode test facility for modifying organic materials with accelerated electrons (Photo: Fraunhofer FEP, Finn Hoyer)

The cement industry is a major source of greenhouse gas emissions. In order to develop CO2-reduced cements, the Fraunhofer FEP is therefore conducting research into the biogenic material development of secondary limestone using phototrophic microorganisms under CO2 consumption. These are able to fix and convert carbon dioxide from the atmosphere through photosynthesis. The focus of research is to implement the process of microbiological limestone formation, which has existed in nature for billions of years, on an industrial scale. Biogenic limestone synthesis, based on the microbial biomineralization process, is supported by the biostimulating potential of ion beam processes. Low-energy, non-thermal electron beam processes influence the metabolic processes of phototrophic microorganisms, which can increase the effectiveness and efficiency of biogenic limestone synthesis.