Ultrafast pulsed (USP) lasers are already standard in display production today, and even more and even larger applications will be added in the coming years.

At the 6th "USP Workshop: Ultrafast Laser Technology" organized by the Fraunhofer Institute for Laser Technology ILT in Aachen, the necessary technology and suitable processes were presented. The spectrum ranges from ultra-strong beam sources to processes that can be used to increase the surface area of a metal electrode for hydrogen production thousands of times over.

UKP experts have been meeting in Aachen every two years since 2011 to discuss new ideas and trends from industry and research in a personal atmosphere. This year, the networking event took place online. The Fraunhofer ILT made a virtue of necessity and used the opportunity for virtual laboratory tours, which were previously not feasible at a face-to-face event with the large number of participants.

World records for beam sources

The core topics of the UKP workshop include developments in beam sources, process knowledge and potential applications.

The Fraunhofer-Gesellschaft is setting global standards for beam sources with its Cluster of Excellence Advanced Photon Sources CAPS. The world record is held with 10 kW average power from a coherently coupled fiber laser at the Fraunhofer IOF in Jena. At the Fraunhofer ILT in Aachen, as Institute Director Prof. Constantin Häfner reported, a 5 kW slab system will be ready for use this summer. The new feature is pumping with six instead of two pump jets on each slab. The 6 kW diode pumping power will ultimately become 2 kW UKP power per amplifier stage. Both in Jena and Aachen, the beam sources are available to industrial partners and interested parties for testing in CAPS application laboratories.

Dr. Rudolf Weber from the University of Stuttgart presented an interesting statistic on the question of when such outputs will become the standard in industry: according to this, the average output of USP systems in both industry and research has doubled every three years over the last 20 years. According to the statistics, the introduction of multi-kW systems in standard industrial processes can be expected by 2025. It is already foreseeable that new laser processes for microstructuring surfaces with kW beam sources will open up new markets.

The significance of the new laser sources for research can hardly be estimated, as Prof. Häfner showed in his outlook. As "secondary sources" for short-pulsed X-ray, electron or particle beams, they will open up completely new possibilities in medicine, particle physics or materials science.

New process knowledge: Using bursts correctly

Research into the interaction of USP laser radiation with materials has been going on for at least 30 years. But it is only in recent years that reliable process windows for industrial applications have been developed. One expert in this field is Beat Neuenschwander from Bern University of Applied Sciences, who once again presented new results at this year's USP workshop. This time he focused on the processing of silicon and other semiconductor materials with single and multiple pulses (bursts). With silicon, the ablation rate can be significantly increased with bursts, whereby the number of pulses and the wavelength have different effects for different materials.

Daniel Förster from LightPulse LASER PRECISION in Stuttgart and Dr. Norman Hodgson from Coherent, Inc. presented detailed studies on how bursts affect the ablation of metals. In his presentation, Hodgson gave a crash course on the optimum process parameters for nine materials, three wavelengths, different pulse durations and burst frequencies. From the various experiments, he was able to derive a tabular "Wavelength selection guide for ultrafast laser machining".

Dr. Roswitha Giedel-Wagner, GFH GmbH, discussed X-ray emission, a particularly critical effect when using industrial USP lasers. At GFH, laser machines for micromaterial processing with ultrashort pulse lasers are built for a wide range of applications, emissions are precisely measured and the protection concepts are adapted accordingly. Due to the current Radiation Protection Ordinance, the feasibility of the simplest processes without a complex approval procedure is often in question. The good news is that a 1 mm steel housing already protects the user from the emitted radiation.

In addition to the beam sources, the optics of the USP systems have also proven to be a key driver of innovation in recent years. Georg König from the Chair of Technology of Optical Systems TOS at RWTH Aachen University summarized the progress made over the past two years in his presentation. In addition to ever better multi-beam systems, he looked at the simulation of entire processes and new optics (diffractive optical elements, spatial light modulators, Bessel beams) as well as the realization of the associated technology.

More applications in the semiconductor sector

In addition to the discussion of process knowledge, the presentation of new applications is a core concern of the UKP workshop. Dr. Koji Sugioka from RIKEN in Japan gave a broad overview right at the beginning. On the process side, there are advances in structuring, drilling and cutting (especially dicing), which in turn are driving commercial applications in the semiconductor industry and in the automotive sector. He also sees great prospects for hybrid processes, where the precision of USP lasers combined with the speed of other laser types enables higher productivity. Looking to the future, Sugioka sees the nanostructuring of surfaces, but also the synthesis of new materials such as nitrogen-vacancy (NV) diamonds for quantum technology.

Applications in the semiconductor industry were presented by Dr. Kees Biesheuvel (ASM Laser Separation International). The ablation of silicon wafers is important here, where the USP laser works with micrometer precision and does not cause cracks. The systems are also indispensable for the precise removal of coatings, which considerably simplifies subsequent separation processes. The systems are used both in semiconductor production and in the display industry.

Laser polishing represents a new area of application within USP technology. Astrid Saßmannshausen from Fraunhofer ILT presented the complete process chain for this. In this machining process, it is important to melt the surface and not remove it. With suitable process parameters, the surface roughness can be reduced across a broad spectrum in a two-stage process and a roughness of less than 0.1 µm can be achieved. New kW beam sources and bursts up to the GHz range will further improve productivity.

USP lasers for the energy of the future

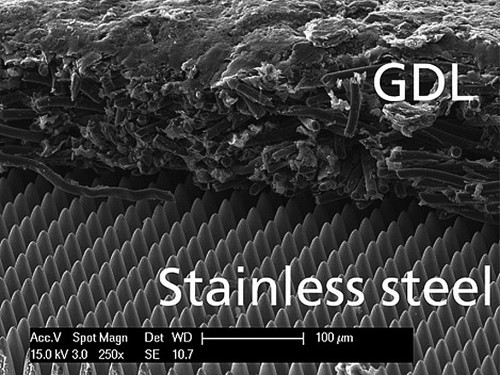

Battery and hydrogen technologies offer a really large field of application for USP lasers. In his presentation, Dr. Karsten Lange from Fraunhofer ILT showed both the environment and specific examples. There are several starting points in hydrogen technology. The most impressive is certainly the enlargement of the effective electrode surface by a factor of 1600 through laser structuring, which the scientist was able to achieve.

The USP laser can increase the surface area of hydrogen electrodes by a factor of more than a thousand

The USP laser can increase the surface area of hydrogen electrodes by a factor of more than a thousand

From summer 2021, laser processes for battery production will be researched at Fraunhofer ILT in a dedicated battery center. In the picture: Roll-to-roll system

From summer 2021, laser processes for battery production will be researched at Fraunhofer ILT in a dedicated battery center. In the picture: Roll-to-roll system

Battery technology today is all about increasing both energy density and power density. Laser processes are being developed in both fields. Lithium deposition is currently a problem with high power densities (i.e. fast charging or discharging processes). The USP laser can be used to introduce micropores into the electrodes of the batteries and thus reduce the problem. The technology is to be investigated in a special battery laboratory at Fraunhofer ILT from summer 2021. The decisive factor in the widespread introduction of USP lasers in the production of batteries and fuel cells will be the power scaling of the beam sources. For superior productivity, USP lasers with 5 to 10 kW are required here.

7th UKP workshop: Ultrafast Laser Technology - Review and outlook for 2023

USP lasers have arrived in the industry. However, the 6th UKP workshop also showed how much process knowledge is still being developed in order to bring the full potential into production. "The ultimate goal would be a universal laser lathe that could be used to perform a wide range of machining tasks," says workshop organizer Prof. Arnold Gillner, summarizing the vision.

High repetition rates, high performance and how to get the power onto the workpiece efficiently - these are keywords that will certainly also play a role at the next UKP workshop on April 26 and 27, 2023 in Aachen. "Hopefully we'll meet again in person then," concludes co-organizer Martin Reininghaus, expressing the wishes of all those involved.

All images: Fraunhofer ILT, Aachen.