The V2023 - International Conference & Exhibition took place at the International Congress Center Dresden from September 18 to 21, 2023. Attendance was very good with 460 people from 25 countries. The conference, which was held in English for the first time, highlighted the importance of thin films for various areas of industry and society in the five workshop topics Energy, Tools & Components, Optics, Biomedical Applications and Digital Data.

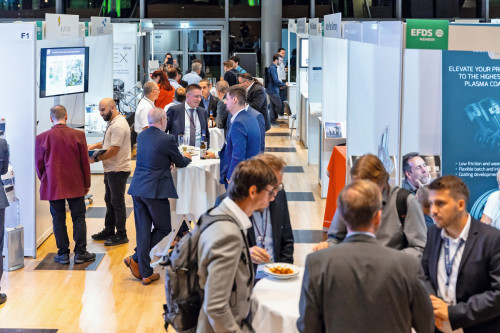

The conference documented the significance of these cross-sectional technologies as important contributions to solving global problems such as sustainable energy, climate, mobility and environmental protection. The lecture program was complemented by a poster exhibition. The conference was accompanied by an industrial exhibition in which around 80 companies and institutions presented their processes, products and services. Social events such as the industry evening and the conference dinner rounded off the program.

Attendance was very good with 460 people from 25 countries

The presentations

Around 80 companies presented their innovations at the industrial exhibition with a view of the Elbe and the Elbe metropolis Dresden"Plasma and Surface Technologies for Energy Applications and Sustainability" - Prof. Dr. Elizabeth von Hauff, Fraunhofer FEP, Dresden, introduced her opening speech with the statement that the Fraunhofer-Gesellschaft also sees its mission in the development of innovative solutions for acute problems of our industrial society; this includes climate change and measures to reduce human influence on it. The Fraunhofer FEP has many years of experience in the development and application of electron beam and plasma technologies and their transfer into industrial products. In her lecture, von Hauff presented results from the fields of energy storage and conversion, sustainable packaging, biomedical and life sciences, human/machine interface and sensor technology, among others. Customized hardware platforms and processes should enable the deposition of functional and/or critical materials on a variety of surfaces, including flexible, rigid or biologically active substrates. This was demonstrated using the example of plasma synthesis of precursors for the chemical industry.

Around 80 companies presented their innovations at the industrial exhibition with a view of the Elbe and the Elbe metropolis Dresden"Plasma and Surface Technologies for Energy Applications and Sustainability" - Prof. Dr. Elizabeth von Hauff, Fraunhofer FEP, Dresden, introduced her opening speech with the statement that the Fraunhofer-Gesellschaft also sees its mission in the development of innovative solutions for acute problems of our industrial society; this includes climate change and measures to reduce human influence on it. The Fraunhofer FEP has many years of experience in the development and application of electron beam and plasma technologies and their transfer into industrial products. In her lecture, von Hauff presented results from the fields of energy storage and conversion, sustainable packaging, biomedical and life sciences, human/machine interface and sensor technology, among others. Customized hardware platforms and processes should enable the deposition of functional and/or critical materials on a variety of surfaces, including flexible, rigid or biologically active substrates. This was demonstrated using the example of plasma synthesis of precursors for the chemical industry.

Coatings for tools and components

Hard coatings can increase the service life of tools and also the processing speed. Super-lubricating coatings reduce friction losses, making them economical and environmentally friendly. Innovative surfaces can also contribute to the replacement of critical materials.

"The Influence of Pulse Parameters on Plasma Properties and Performance of HiPIMS Coatings for Cutting Tools" was the topic of the presentation by Dr. Stephan Bolz, CemeCon AG, Würselen. High-strength and lightweight materials are becoming increasingly important in the aerospace and automotive industries. The processing of materials such as stainless steels, hardened steel or titanium and high-temperature alloys places high demands on the adhesion, hardness, surface finish and chemical resistance of the coatings. High-performance PVD processes such as HIPIMS are increasingly being used. They can achieve a very high ionization of the metal atoms and thus produce dense, hard, well-adhering and droplet-free coatings. The performance of such coatings was demonstrated using the example of an (Al,Ti,Si)N coating. Tools made of austenitic steel coated with this coating showed significantly improved performance during turning.

The presentation "HIPIMS - Coating Technology for a New Product Generation of Tools and Components" by Dr. Philipp Immich, IHI Hauzer Techno Coating B.V., Venlo, also provided information on the versatile high-pulse technology. Compared to sputter or arc coatings, tools coated in this way can achieve better performance in milling or forming, for example. The same also applies to tribological or decorative applications. IHI Hauzer supplies and operates industrial-scale systems for various applications, industrial sectors and product sizes. They are suitable for series production and can be integrated into modern production environments. Upscaling in systems of different sizes is possible and a good cost/performance ratio is achieved.

"Modulus and Yield Strength Measurements of ultra-thin ALD-Coatings in a Thickness Range between 5 nm and 100 nm" - Dr. Thomas Chudoba, ASMEC GmbH, Dresden, provided information on this topic. Atomic Layer Deposition (ALD) is one of the most suitable processes for applying uniformly thick coatings on curved surfaces and in holes. However, the mechanical properties of ALD layers cannot be measured with conventional nanoindenters. The lecturer presented a measurement method that can be used to determine the Youngs modulus and tensile strength of very thin layers. It is based on fully elastic indentations with a spherical indenter, whereby the influence of the substrate is completely eliminated. The method was tested on Al2O3 layers with thicknesses of 5 - 100 nanometers on Si (100) substrates. It can be used for the application-related measurement and optimization of extremely thin layers, for example for a combination of ALD and physical vapour deposition (PVD) processes for coating tools and components.

Coatings for energy technology

European experts are working specifically on sustainable energy technologies to respond to climate change and the geopolitical situation. Surface and plasma technologies can make important contributions to this. The range of possibilities extends from hydrogen and battery technologies to plasma-based synthesis and photovoltaics. Two examples will demonstrate this.

"Roll-to-Roll ALD Coatings for Battery Cell Interfaces" - Dr. Andrew Cook, Beneq Oy, Espoo, Finland, explained how his company uses ALD technology to deposit extremely thin layers to modify the surfaces (interfaces) of cathodes, anodes or separators of battery cells. Atomic Layer Deposition (ALD) can help to increase thermal resistance, stabilize SEI layers, suppress dendrites, prevent the dissolution of transition metals and improve the contact between the layers with the aim of improving the performance of lithium-ion batteries. The speaker presented the R2R ALD system developed at Beneq for high volume production.

"Vacuum Coating for Lithium-ion Batteries: The Route to Commercial Production on the Example of Metal-Polymer Current Collectors" - Dr. Markus Piwko, Von Ardenne GmbH, Dresden, provided information on how vacuum processes can contribute to further increasing the performance, shortening the charging time and improving the safety of lithium-ion batteries. To achieve this, technologies such as vacuum processes must be integrated into the production process. This was demonstrated using the example of thin metal-coated polymer films, which can be used as a replacement for the thicker metal films previously used as collectors (current collectors). The new collectors are designed to make it more difficult for battery cells to leak and thus reduce the risk of fire. They melt when a critical temperature is reached and interrupt the current flow, preventing short circuits. Von Ardenne is cooperating with the Fraunhofer FEP and partners in this field in the BMBF PolySafe project. The aim is also to provide the necessary system technology for industrial application.

Coatings for optics and optical components

Contacts and networking: During the breaks, business was initiated and technical discussions heldPracticallyall optical components require surface treatment or coating systems in order to achieve optimum performance. Vacuum and plasma processes are frequently used. The workshop analyzed various vacuum coating processes and their advantages and disadvantages and also presented current applications. Dr. Astrid Bingel, Fraunhofer IOF, Jena, provided information on the topic of "Antireflection Coatings for Objective Lenses with Requirements for Quantum Optical Experiments". Quantum optical experiments for future quantum computers require ultra-high vacuum conditions in vacuum quartz cells. The experiments require lasers with different wavelengths and angles of incidence. By combining nanostructures and thin layers, lenses consisting of many lenses can be produced. Light losses due to unwanted reflection must be prevented at all costs. The lecturer presented the requirements and initial approaches to a lens solution. Quantum computer experiments are planned.

Contacts and networking: During the breaks, business was initiated and technical discussions heldPracticallyall optical components require surface treatment or coating systems in order to achieve optimum performance. Vacuum and plasma processes are frequently used. The workshop analyzed various vacuum coating processes and their advantages and disadvantages and also presented current applications. Dr. Astrid Bingel, Fraunhofer IOF, Jena, provided information on the topic of "Antireflection Coatings for Objective Lenses with Requirements for Quantum Optical Experiments". Quantum optical experiments for future quantum computers require ultra-high vacuum conditions in vacuum quartz cells. The experiments require lasers with different wavelengths and angles of incidence. By combining nanostructures and thin layers, lenses consisting of many lenses can be produced. Light losses due to unwanted reflection must be prevented at all costs. The lecturer presented the requirements and initial approaches to a lens solution. Quantum computer experiments are planned.

"Recent Results and Future Demands on Optical Coating Technology" - Dr. Michael Vergöhl, Fraunhofer IST, Braunschweig, spoke about developments at the Fraunhofer IST in the field of coatings for optical components and systems. The focus of the process technology was on magnetron sputtering, with which coating processes of the highest precision are possible. As examples, the lecturer showed the coating of curved

curved surfaces with specific gradients and thin substrates. New (additional) sensors and the use of artificial intelligence make it possible to further optimize process and coating monitoring. A data comparison of the existing and new sensors allows new insights into the process. Specifically, Vergöhl presented new approaches to optical broadband monitoring, such as real-time ellipsometry in a rotary coater with a high rotational speed.

Dr. Christian Schindler, Bühler Alzenau GmbH, reported on the topic of "Ion Beam Figuring (IBF) as a Part Of An Optics Production Line". Today, IBF is a proven technology for realizing optical surfaces with very low form errors (high accuracy). It offers advantages compared to traditional polishing processes such as magneto-rheological processing. No additional structures or roughness are created so that ultra-smooth surfaces can be produced, e.g. for laser applications. IBF is increasingly used for high-precision (but not high-end) optical or mechanical components with a required peak-to-valley (PV) error of around lambda/20. Curved or large substrates can also be processed. Continuous production without human intervention is also possible.

Coatings for biomedical applications

Coatings are becoming increasingly important in medical technology; implants are becoming more biocompatible or can be provided with barrier layers that prevent the implant base material from interacting with the surrounding tissue, for example, or have a positive effect on abrasion stability. Harald Holeczek, Medicoat AG, Switzerland, provided information on "Thermal Spray Coatings on non-metallic Materials for Medical Implants - Innovations in Coating Polymers and Ceramics". Plasma spraying in an atmosphere (APS) or in a vacuum (VPS) is used to coat implants with titanium or hydroxyapatite on the surfaces in contact with the bone. The rough and microstructured layers and the coating process are already state of the art. New and innovative is the use of ceramic implants, which are applied directly to their surface using VPS with high adhesion. Temperature-sensitive polymer implants (PEEK), which can also be coated by plasma spraying, are also increasingly being used.

The service life of knee implants, for example, can be between 15 and 20 years, but premature failure is possible due to wear or breakage. In her presentation "Performance of DLC Coatings on Knee and Spine Replacements", Dr. Susan Schmidt, IHI Ionbond AG, Zurich, reported on the results of a study on how diamond-like carbon (DLC) coatings can improve surface properties and contribute to a longer service life. The coatings to be tested were applied by plasma activated chemical vapor deposition (PACVD) to components of knee and spine implants (CoCrMo, TiAlV) and to test substrates. They were tested in accordance with ISO 14243-1 and ASTM F732. The DLC-coated samples showed clear superiority over uncoated samples in terms of wear, ion release and corrosion. An increased service life and fewer revision interventions are expected.

"Advancing Healthcare through PVD Coatings: The Benefits in Medical Applications" - In her presentation, Dr. Canet Acikgoz Oerlikon Surface Solutions AG, Balzers, Liechtenstein, introduced her company's BALIMED coatings, which are increasingly being used in medical technology. They offer advantages such as low friction, high wear resistance and chemical resistance. The coatings, which are only a few micrometres thick, are deposited using reactive PVD and can be optimized for specific applications, for example to create new antimicrobial surfaces. These can be used in the field of orthopaedic and medical devices instead of conventional silver coatings. This enables fine tuning between antibacterial behavior and toxicity.

Quantum technology as a driver of innovation

As part of the lecture program, the possibilities of thin-film technology to support the further development of quantum-based systems and the opportunities for transferring these from research to industrial products were reported on. The following three presentations provided information on the topic.

In his presentation "Nanomaterial Systems for integrated Quantum Photonics Applications", Dr. Falk Eilenberger reported on the activities of the Fraunhofer Institute for Applied Optics and Precision Engineering IOF, Jena, and partners. In the CO2M project, sophisticated optical components for the three channels of the spectrometer (NIR, SWIR1 and SWIR2) are being developed for two earth observation satellites for measuring greenhouse gases. The so-called PG+P dispersers each consist of two prisms and a grating. A special grating design is used in which functional optical layers (various anti-reflective and absorbing layers as well as laser-modified surfaces) are applied by IAPVD and ALD.

Dr. Manuela Junghähnel, Fraunhofer IZM ASSID, Moritzburg, presented the BMBF-funded project "Quantum computer in the solid state - Qsolid" in her paper "Advanced Heterogenous Integration Packaging Technologies for next Generation Quantum Computing". Its aim is to develop a fault-tolerant quantum computer based on superconducting qubits and integrate it into the existing supercomputer environment at Forschungszentrum Jülich. A scalable packaging solution is to be developed as part of the "cryogenic packaging" sub-project. The challenge here is the combination of effective thermal decoupling and high-density superconducting wires between the quantum processing unit and the controlling electronics under cryogenic conditions. The "silicon flex interposer approach" developed at IZM ASSID makes this possible by using TiN-based superconducting wires and bump bonds made of indium. The speaker presented the packaging concept developed at IZM ASSID, in which various coating processes such as PVD, reactive ion etch (RIE) and electrochemical deposition (ECD) are used.

In the presentation "Quantum Technologies and possible Implications for Thin-film Technologies", Dr. Thomas Strohm, Robert Bosch GmbH, Stuttgart, provided information on the many possible products (e.g. quantum computers or quantum sensors) based on quantum technologies and the possible applications of thin-film processes for their realization. Quantum sensors (e.g. quantum magnetometers or quantum gyroscopes) are already relatively well developed. These use diamond-based layers with embedded NV centers, diffusion barriers for rubidium or cesium or temperature-stable layers. Examples of applications include new and more sensitive sensor types based on quantum effects that use atoms, semiconductor spins or photons, as well as sensors for measuring magnetic fields, acceleration, rotation, time-electric fields and mass.

Photos: René Jungnickel