The same technologies that are used in the demanding semiconductor industry are becoming important in power electronics. At the same time, a secure electrical and thermal connection to the DCB substrate must be maintained. New test methods are needed to verify this.

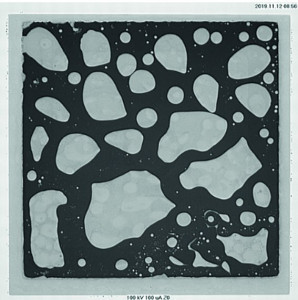

X-ray image of a joined IGBT with very poor soldering qualityThetrend in power electronics towards 'new' semiconductor materials and processes is beingdrivenin particular by the electrification of the automotive industry and renewable energies or the energy transition. However, standards and requirements for power electronics that were previously reserved for logic semiconductors are also becoming established in transportation, consumer electronics, telecommunications and industrial applications.

X-ray image of a joined IGBT with very poor soldering qualityThetrend in power electronics towards 'new' semiconductor materials and processes is beingdrivenin particular by the electrification of the automotive industry and renewable energies or the energy transition. However, standards and requirements for power electronics that were previously reserved for logic semiconductors are also becoming established in transportation, consumer electronics, telecommunications and industrial applications.

Semiconductor materials are an important aspect: Whereas over 90% of integrated circuits used to use silicon, 'new' materials such as gallium nitride/gallium arsenide or silicon carbide are now increasingly being used. This trend also enables higher switching frequencies and lower losses in power electronics.

Nevertheless, the substrates of power modules continue to be manufactured on the basis of ceramic and copper (DCB substrates). This is because any heat generated can be dissipated very quickly, reliably preventing power losses and damage to the modules.

This combination results in a special requirement: the interface between the 'new' semiconductors and the DCB substrate must be designed to ensure safe electrical and thermal conductivity. This is where the function and reliability of the assembly is decided to a large extent.

Currently, soldered joints and silver sintered joints are mostly used. However, the latter do not produce a homogeneous layer that can be verified using conventional test methods such as X-ray or ultrasound microscopy. These methods are therefore unsuitable. If the joint is now sintered instead of soldered, a fast and reliable quality test must be developed.

Contact thermography research project

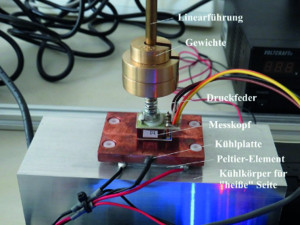

Design of the test set-upThistask has been addressed by a research approach which, if successful, could become indispensable for the high-volume series production of power modules for electric drives and converters for renewable energies - contact thermography. The Center for Microtechnical Production (ZmP) at the TU Dresden, Budatec GmbH, Berlin and Kraus Hardware GmbH, Großostheim/Ringheim are currently involved in its further development. The project is funded by the Central Innovation Program for SMEs (ZIM) and is based on the work of the ZIM project 'Dynatherm'. In this project, contact thermography with various sub-processes has already been developed in principle.

Design of the test set-upThistask has been addressed by a research approach which, if successful, could become indispensable for the high-volume series production of power modules for electric drives and converters for renewable energies - contact thermography. The Center for Microtechnical Production (ZmP) at the TU Dresden, Budatec GmbH, Berlin and Kraus Hardware GmbH, Großostheim/Ringheim are currently involved in its further development. The project is funded by the Central Innovation Program for SMEs (ZIM) and is based on the work of the ZIM project 'Dynatherm'. In this project, contact thermography with various sub-processes has already been developed in principle.

For the now extended ZIM project, the project partners have now set themselves the task of developing an inline-capable testing apparatus and also want to test it in production.

Budatec is responsible for all the work involved in designing and implementing the system technology, optimizing the sensors and carrying out the series of measurements. TU Dresden is optimizing the sensor head used and evaluating the test results. Kraus Hardware designs and constructs the control and evaluation electronics and is involved in carrying out the series of measurements.

As an EMS service provider, Kraus has long relied on test combinations for the reliable validation of electronic assemblies. Extensive experience in ICT tests, flying probe, boundary scan, functional testing and even HDR inspection helps here. Against the background of this expertise, Andreas Kraus, Managing Director of Kraus Hardware, is confident that the project will make an important contribution in the field of electromobility and electric drives as well as in the large application field of renewable energies. At the same time, a greater understanding of soldering and sintering processes is being built up internally and the existing expertise in measurement and control technology is being expanded.