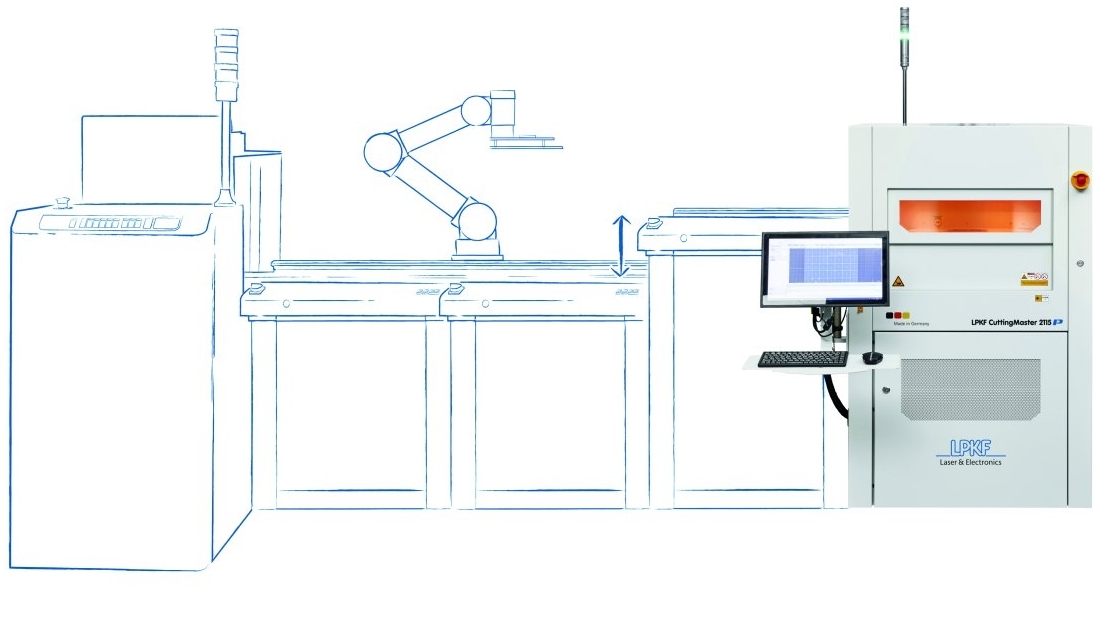

Together with its laser depaneling systems, LPKF now also offers solutions for handling PCBs before and after the cutting process, thus facilitating integration into the line The laser machine for depaneling is supplied complete with an automated feeding and unloading system that meets the requirements of technologically up-to-date and efficient PCB production. The new automation range complements the LPKF CuttingMaster 2000 and 3000 depaneling systems as well as the LPKF MicroLine 2000. An additional advantage for machine users is that there is one contact person for the depaneling process who supervises the process itself and its automated integration into the line production. This often eliminates the need for time-consuming additional communication channels to or between several service providers.

The modular handling concept is flexibly and precisely tailored to customer requirements for large or small, assembled or unassembled PCBs in any shape or combination. The automation unit can be equipped with a variable cobot. Various carrier and gripper solutions are used for specific applications. They are designed in such a way that they can handle all the different panel layouts used by the user. It is also possible to collect the PCBs in customer-specific blister packs. LPKF offers suitable solutions for both mass production and high-mix, low-volume production. The portfolio ranges from the addition of individual modules to a completely autonomous stand-alone solution for the entire depaneling process. Integration into SMT lines is also easy to implement.

The LPKF CuttingMaster can optionally be equipped with an automation solution and/or a variable cobot