Residue-free fluxes or even flux-free soldering are increasingly in demand. However, the effort involved would be great - perhaps even greater than adjusting to flux and solids content in modern soldering agents in conjunction with modern soldering system technology.

"We are looking for a residue-free flux!" or "Isn't there an SMD solder paste without flux?" - such inquiries are no longer rare in the soldering industry. The vision of a soldering process that works without annoying fluxes and their residues has occupied solder manufacturers, soldering system manufacturers and component manufacturers alike for decades.

Low-oxygen soldering atmospheres such as vacuum, inert gas or saturated steam (vapor phase) reduce or prevent the formation of oxides in the soldering process, but cannot eliminate existing oxide layers on the soldering partners. Soldering processes with active process gases, such as in low-pressure plasma, are able to break up the oxides, but require complex and cost-intensive furnace technology, which (like vapor phase technology) also only has limited inline capability.

Flux-based soldering processes and the corresponding soldering agents are therefore state of the art in component production. The most important are solder pastes for the reflow soldering of surface-mount components (SMD), low-solids fluxes for the wave soldering of THT components in wave and selective soldering systems and solder wires with flux core(s) for manual and automated piston, induction, hot air and laser soldering processes. The currently useful flux content in solder wires and SMD solder pastes as well as the solid content in fluxes for these wave soldering processes will be shown here from the perspective of a solder manufacturer. The main focus is on so-called no-clean flux types.

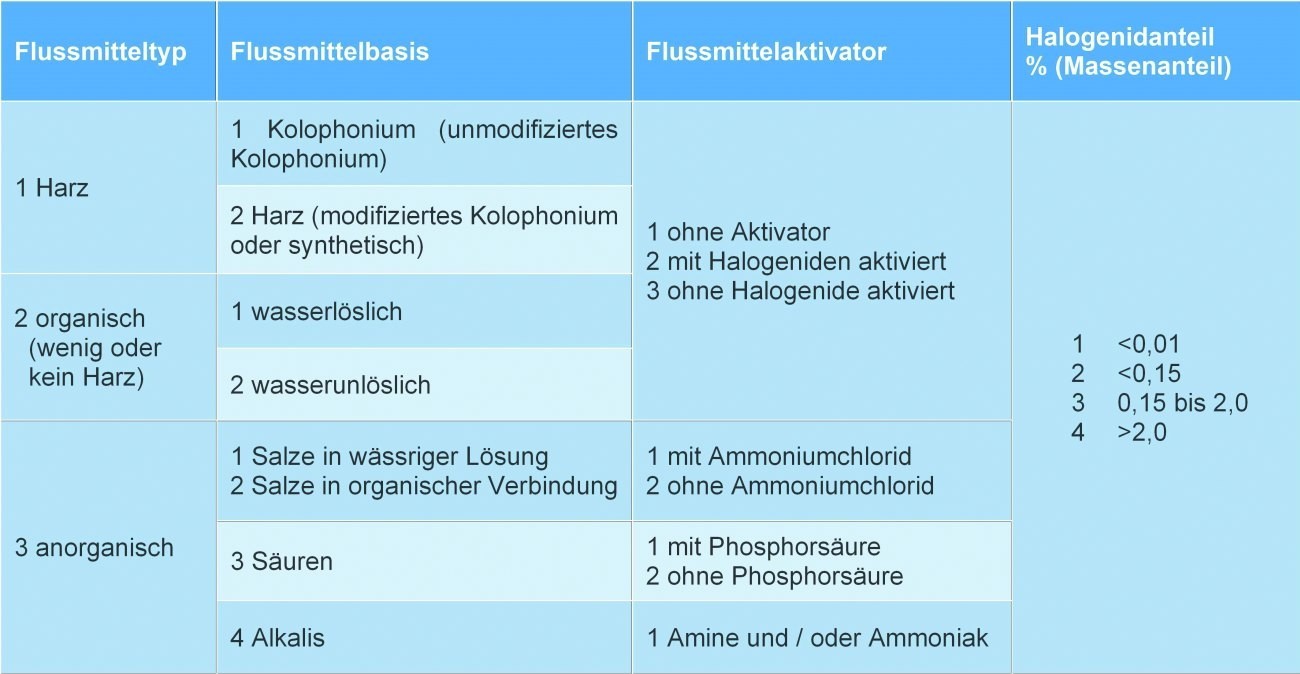

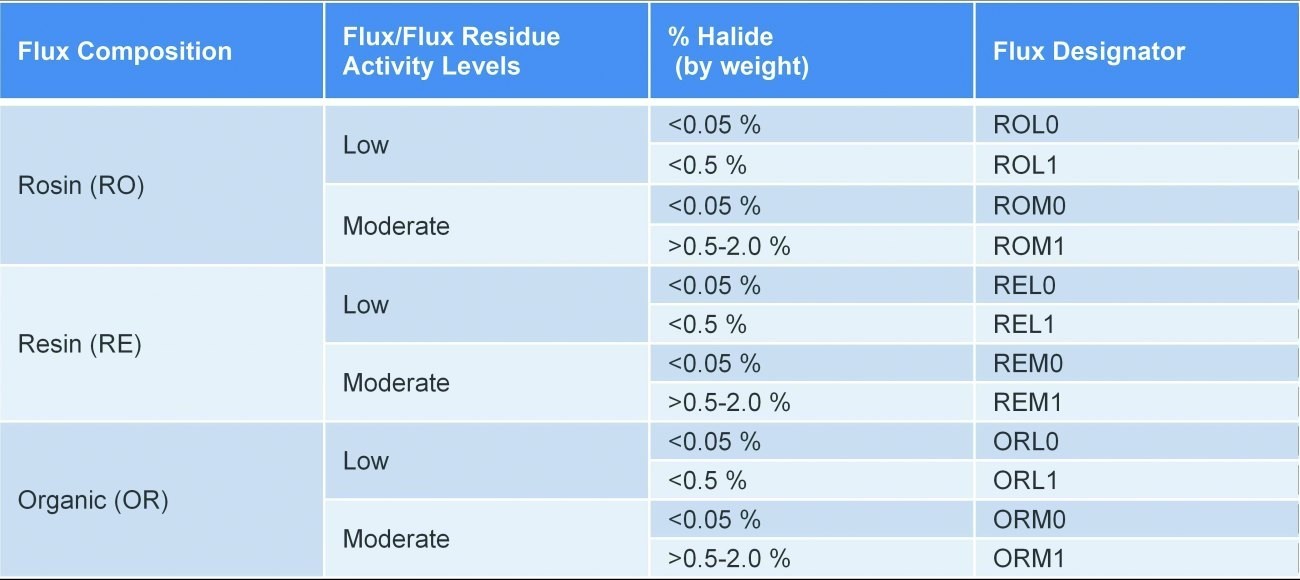

Table 1: Classification of fluxes according to EN ISO 9454-1:2016

Table 1: Classification of fluxes according to EN ISO 9454-1:2016

1 Flux-filled soft solder wires (tubular solders)

According to the standard DIN EN ISO 12224-1 'Solid solder wires and flux cored tubular solders - Specification and test methods - Part 1: Classification and requirements', soft solder wires with flux core(s) must meet the requirements for the corresponding alloy according to ISO 9453 and the corresponding flux type according to ISO 9454-1. The current EN ISO 9454-1:2016 and the test standards EN ISO 9455-1 ff. determine the properties of the fluxes. If the selection of fluxes is limited to the types commonly used in assembly production (flux residues with a high SIR value (surface resistance value) >100 MΩ and no corrosion effect), then these are the halide-free types 1111, 1131, 1231, 2231 and the weakly halide-activated types 1122, 1222 and 2222.

The dispersion test described in DIN EN ISO 12224-1:1998 and the minimum dispersion values specified therein, based on special tubular solders, are only permissible for lead-containing alloys (Sn63Pb37(E), Sn60Pb40(E) or Sn62Pb36Ag2). As the propagation of lead-free solders is generally somewhat worse than that of lead-containing solders, it may not be possible to achieve the values listed in Table 2.

In addition to Sn60Pb40 and Sn96.5Ag3Cu0.5, the much more up-to-date EN ISO 9455-10:2013 also allows 'any other solder and test temperature combination as agreed between the customer and manufacturer'. However, a minimum spreading area or a minimum spreading ratio is not specified. The effectiveness of the flux is determined by the spreading ratio compared to specified standard reference fluxes.

Achieving 'type-specific' effectiveness depends not only on the qualitative activation, but also on the solids content in the flux or the flux content (in wire or paste). The solids content of common no-clean fluxes for the wave and selective soldering process is between 2.0 and 5.0% by weight. Depending on the application, SMD solder pastes have a flux content of 10 to 30 % by weight and flux-filled solder wires are offered with flux contents of 0.7 to 3.5 % by weight, today as in the past, i.e. leaded or lead-free.

Table 2: Minimum spread for special flux-filled tubular solders according to EN ISO 12224-1:1998

Table 2: Minimum spread for special flux-filled tubular solders according to EN ISO 12224-1:1998

The flux formulations and flux contents for tubular solders developed in the 'lead era' were perfectly matched to the process temperatures specified by the melting temperature of the lead-containing solder alloys during piston soldering. At a soldering tip temperature of 330 to 350 °C, the activators contained in the flux remain functional throughout the entire soldering process and the resin component(s) hardly change color. Depending on the flux type, activation or application, the following flux proportions have become established in assembly production:

- Halide-free resin-based wires: 2.5-3.5 % flux

- Resin-based wires containing halides: 2.2-2.8 % flux

- Special wires for SMD rework: 0.7-1.5 % flux

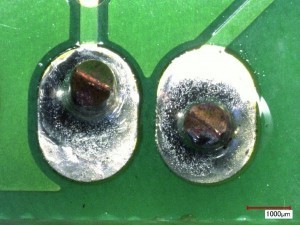

When the RoHS came into force in 2006, attempts were initially made to adopt these formulations 1:1 for lead-free solder wires. However, as the soldering temperature had to be adjusted to the melting temperature of the lead-free solder alloys and thus raised by 30 to 50 K, this was only a stopgap solution. Although the effectiveness of the flux was sufficient according to EN ISO 9455-10, the flux residues became much darker(Fig. 1) and the flux splashed heavily during soldering. In addition, new non-contact soldering processes such as laser or induction soldering were developed, which introduce even more thermal energy into the solder joint in an even shorter time. In order to meet these requirements, the fluxes not only had to be modified, but in most cases completely redeveloped. For this purpose, other flux-compatible resins (ideally with self-activation), dicarboxylic acids with a suitable (higher) activation temperature and additives had to be found and, of course, the 'correct' mixing ratio had to be achieved.

Modern, lead-free tubular solders are stable against the temperatures occurring in the soldering process, allow adequate process times, leave behind light-colored, inconspicuous flux residues(Fig. 2) and also guarantee perfect, reproducible soldering results. However, the flux content of these wires and the resulting flux residue quantities on the assemblies have not changed noticeably. However, the higher soldering temperatures result in more soldering fumes. This shortens the cleaning and replacement intervals of extraction systems and their filters.

The flux proportions listed above are still common. However, the development of new solder alloys, fluxes and also soldering techniques is certainly not yet complete, so that innovative tubular solders are offered with flux contents that are 0.5 to 1.0 % lower than those listed above (with the exception of rework solder wires).

The field solder wires ISO-Core 'Ultra-Clear' (1231, REL0), ISO-Core 'Clear' (1222, REL1) and ISO-Core 'RA-Clear' (1223, REM1), each with 2.2 % standard flux content, have been adapted to the requirements of modern assembly production:

- Minimal, crystal-clear, high-resistance, colophony-free, non-corrosive flux residues

- High wetting speed and large spread

- No flux splashes

- Low, low-odour soldering fumes

- Gentle on soldering tips

- No flux spattering

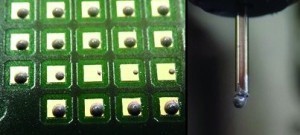

In particular, compliance with the composition of the solder alloy, the flux content and the wire cross-section requires precise, continuous production monitoring and is ensured by state-of-the-art inline inspection systems in the production process:

- Identification of flux leaks and fluctuations

- Detection of changes in the solder alloy

- Identification of inclusions and other wire anomalies

- Continuous monitoring of the wire cross-section (multi-axis diameter control).

In the event of deviations from the set measured values, the faulty wire is sorted out so that customers can be guaranteed consistent wire quality.

2 SMD solder pastes

An SMD solder paste is probably the most complex soldering agent. Solder and flux in one product, optimally matched to several processes within the assembly production line: paste application (printing / dispensing) - component assembly - reflow soldering (convection / vapor phase) - inspection (AOI / ICT).

Like tube solders, SMD solder pastes are also regulated by corresponding standards. Since the national standard DIN 32513-1 from 2005 was withdrawn without replacement, the standard setter recommends the use of DIN EN 61190-1-2 'Connection materials for electronic assemblies - Part 1-2: Requirements for solder pastes for high-quality connections in electronic assembly'.

With regard to the flux properties of the pastes, reference is made to DIN EN 61190-1-1 'Interconnection materials for electronic assemblies - Part 1-1: Requirements for soft solder fluxes for high quality interconnections in electronic assembly'; for the metal powder content, Part 1-3: 'Requirements for electronic solders and for solid form solders with or without flux for soldering electronic products' applies.

In addition to this, IPC J-STD-004 is an internationally recognized standard for the classification of soft solder fluxes in electronic assembly production and is even more popular in Europe than the aforementioned standards. For reasons of clarity, the flux category 'Inorganic (IN)' and the activity level 'High' are not listed in Table 3. These are insignificant in electronics production.

If we take a look at the list of tests to be carried out for paste qualification in accordance with DIN EN 61189-5-3, the powder particle size, distribution and shape, metal content, viscosity, contour stability and flow, activity (by means of solder ball testing), adhesion and finally the wetting of the paste must be tested in addition to the solder alloy and flux.

Table 3: Classification of fluxes according to IPC J-STD-004 (without inorganic substances)

Table 3: Classification of fluxes according to IPC J-STD-004 (without inorganic substances)

The following properties are required of the paste in the sequence of processes:

- Printing

- Contour stability

- constant printability

- constant paste depot volume

- good release behavior

- good roll-off behavior on the squeegee

- uniform viscosity over long periods of time.

Taken individually, these requirements are quite easy to fulfill. However, covering all the 'duties' automatically leads to 'compromises', as some of the key properties are unfortunately contradictory. For example, the wet adhesive strength of the paste, which is decisive for assembly, has a negative effect on the release of the paste from the printing stencil. A reduction in viscosity (the paste becomes more fluid), which is decisive for adjusting the printability or dispensability of a paste, is also accompanied by an increase in the flux content (i.e. also more flux residue), which in turn influences the contour stability of the paste deposit. Conversely, the flux content cannot be reduced without affecting the rheological properties of the paste.

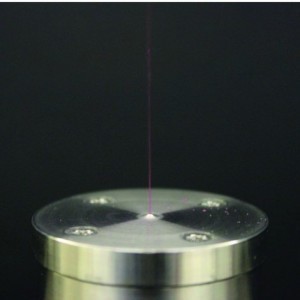

Fig. 3: Contour stability; no settling of the metal powder in the cartridge during dispensing, constant paste volume, no dripping, high, long-lasting tackiness during assembly

Fig. 3: Contour stability; no settling of the metal powder in the cartridge during dispensing, constant paste volume, no dripping, high, long-lasting tackiness during assembly

If the volume of an SMD paste containing 89% metal powder is calculated from the weight of the flux, this results in a flux content of approx. 50% by volume! If the flux content of this paste is reduced by just 1 % by weight (which would also lead to an increase in viscosity of up to 100 Pa-s and would have a considerable influence on the printing properties of the paste), the amount of flux on the board is reduced to just 45 %, which is still by far the highest compared to all other soldering processes!

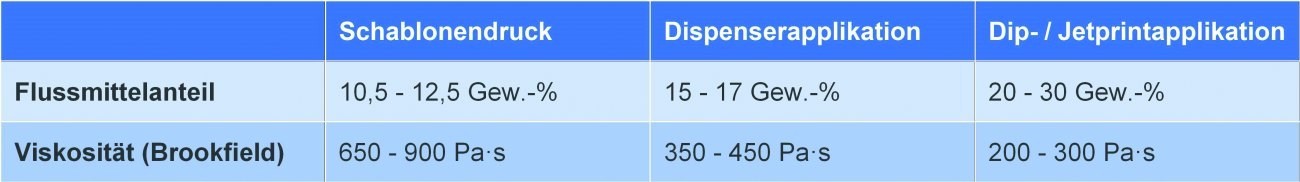

Under certain conditions (soldering in inert process gases, vacuum or superheated steam), the active components of the flux content of an SMD solder paste can indeed be reduced to a minimum. However, this has no noticeable effect on the amount of flux residue, as the activators and resins in the flux component must be replaced by binders and fillers in order to achieve the rheological properties required for the various applications(Table 4).

Tab. 4: Common flux proportions in SMD pastes depending on the application

Tab. 4: Common flux proportions in SMD pastes depending on the application

Since the quantity of the flux mixture in the SMD solder paste is determined by the requirements of the SMD assembly and soldering processes, optimization potential can only be found in the quality of the flux base. The solder pastes ISO-Cream 'Clear' and 'Active-Clear' have been further developed according to these standards and offer the user the following properties:

- Low, colorless and therefore inconspicuous flux residues in no-clean quality

- First-class wetting on all known surfaces

- hardly any escaping and longer cleaning intervals for the reflow oven

- this also greatly reduces outgassing of the paste during the soldering process and therefore void formation on large contact surfaces

- excellent print quality long service life of at least 72 hours

- perfect soldering results with all common soldering profiles

- Insensitive to environmental influences

- Viscosity stability even after long printing breaks.

'Clear' and 'Active-Clear' differ only in their activation. The first version is a REL0 type completely without halides (<0.01%), while the flux of the second paste contains a halide content of <0.15% and therefore corresponds to the REL1 type. All other components of the two pastes - including the metal powder content - and the properties relevant to the soldering process are identical. It would therefore theoretically be possible to switch between the two pastes without having to adjust the parameterization in the corresponding processes.

Fig. 6: Illustration of the difference between wt.% and vol.%

Fig. 6: Illustration of the difference between wt.% and vol.%

3 Fluxes for wave soldering processes

In addition to the requirements of the process and assembly, the selection of the 'right' flux should initially be based on the type of application (flux system). Current wave and selective soldering systems are equipped with spray(Fig. 6) or (micro/drop) jet fluxers(Fig. 7). In order to avoid clogging of the fine nozzles by sticky resins, mainly resin-free fluxes with a low solids content of between 2.0 and 2.7 % are used here. Most of the VOC-free fluxes available can also only be applied with spray or jet fluxers. Although they have been 'declared dead' several times, small and medium-sized service providers still use soldering systems with foam fluxers(Fig. 8). Resin-based fluxes with a solids content of > 2.5 % ensure a stable, fine-pored foam crown and even flux distribution on the circuit board.

The qualitative requirements should be taken from DIN EN 61191-1 section 5.3 'Flux'. According to this, fluxes according to DIN EN 61190-1-1(Table 3) should be used for the production of assemblies, which correspond to types L or M. For assemblies where the flux residues are not removed after soldering (no-clean soldering processes), only fluxes of group L should be used that meet the requirements of DIN EN 61191-1 section 9.2.2 "Degree of purity" without cleaning / testing (C-00)(Tables 5 and 6).

|

0 |

No surface to be cleaned |

|

1 |

One side (the side of the solder group) must be cleaned |

|

2 |

Both sides of the assembly must be cleaned |

|

0 |

No test required |

|

1 |

Test required for rosin residues |

|

2 |

Testing for ionic residues required |

|

3 |

Test the surface insulation resistance as agreed between the user and the manufacturer |

|

4 |

Check the surfaces for organic contamination as agreed between the user and the manufacturer |

|

5 |

Other tests as agreed between the user and the manufacturer |

The requirement for the thermal stability of the flux also varies from soldering system to soldering system. Wave soldering systems with a double wave require a high thermal stability of the flux. This is achieved with an appropriate proportion of solids in the flux. A solids content of 2.5 to 3.5 % is sufficient in a normal atmosphere to ensure the functionality of the flux throughout the entire soldering process until the assembly emerges from the last solder wave.

To ensure good wetting and sufficient penetration, the solder wave temperature in selective soldering systems must be set higher than in conventional wave soldering systems (by up to 20 K). This is based on the lower heat transfer to the solder joint due to a significantly shorter contact time with the small solder wave. On the one hand, the flux must meet this requirement (activity, quantity), on the other hand there is a risk that the flux residues, which are not fully exposed to the soldering temperature and therefore not sufficiently reacted, can lead to failures of the assembly due to corrosion or migration! Fluxes for selective soldering processes should be matched accordingly.

Process-supporting shielding gases that cover the solder pot and reduce the influence of oxygen in the area around the solder waves make it possible to use fluxes with lower solids content. Fluxes with a solids content of between 1.8 and 2.2 % are state of the art, particularly in so-called N2 full-tunnel wave soldering systems. However, since, apart from PCBs and components with ENIG surfaces, all metallization of electronic components and PCBs already has a more or less strong oxide layer before entering the inert process chamber of a full-tunnel wave soldering system, fluxing cannot be completely dispensed with.

The market for electronic fluxes offers a vast number of products with a wide variety of properties. Whether for lead-free or lead-containing solders, for wave or selective soldering processes with an open or encapsulated process chamber with a wide variety of application systems such as spray, foam or jet fluxers, for assemblies in consumer, automotive, power electronics or avionics, users can choose from various special fluxes.

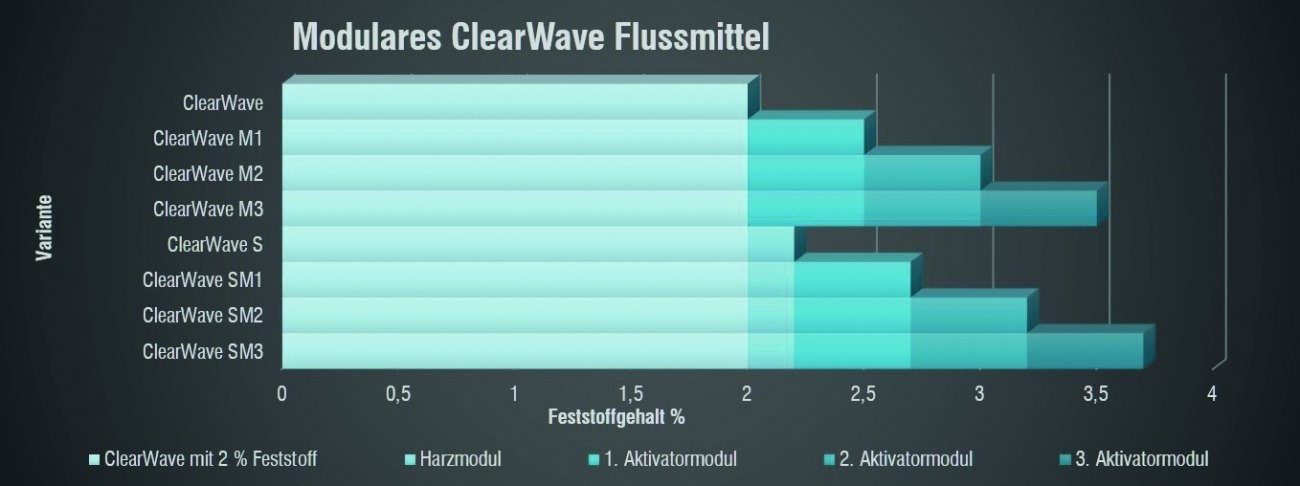

Fig. 10: Structure of the ClearWave system

Fig. 10: Structure of the ClearWave system

With the new ISO-Flux 'ClearWave', Felder presents an innovative, modular and therefore multifunctional electronic flux for demanding assembly production. Starting from a basic ORL0 version with a solids content of 2.0 %, variants with up to 3.7 % solids with and without resin content are available by adding resin and activator modules.

These resin and activator modules are either added to the base flux and customers receive a finished product for immediate use, e.g. ClearWave M3 (resin-free with 3.5 % solids content), or add them themselves as required and generate the ClearWave SM2 variant (resin-containing with approx. 30 % higher activation) from the ClearWave base flux + two activator modules + resin module, for example. This means that every EMS service provider, for example, can react much more flexibly to changing customer requirements in assembly production and achieve greater product variance with their soldering process.

ISO-Flux 'ClearWave' and 'ClearWave S' were developed for the highly qualified lead-free production of commercial electronic assemblies and achieve the best soldering results for circuits with mixed assembly. The flux can be applied to the circuit board using all known fluxing methods (e.g. foaming, spraying, jetting). ClearWave' is ideally suited for wave soldering systems with spray fluxers as well as for state-of-the-art selective soldering systems with drop-jet fluxers, as the jet nozzles cannot stick together.

The resin-containing variant 'ClearWave S' has been optimized for wave soldering systems with foam fluxer application and also for selective soldering with spray fluxer systems. The minimal resin content ensures a very fine-pored foam crown and forms a physical encapsulation (inertization) for flux residues that have not fully reacted.

These two basic variants have already been tested and approved by various electronics manufacturers. Further test results for variants (M1-M3) with higher solids contents will follow in the coming weeks, so that these will be ready for the market in quarter 3 2020.

4 Summary

Fig. 11: Schematic representation of the modular flux compositionIn terms of development technology,lead-free soldering technology and the associated soldering agents have grown out of their 'infancy'. After 15 years, the principle of using lead-free solder in assembly production is clear and the processes are now well established. The phase of optimizing these processes has begun. With this process optimization, it is now also necessary to optimize the corresponding soldering agents. In particular, the requirements of modern selective soldering processes pose a challenge for flux development.

Fig. 11: Schematic representation of the modular flux compositionIn terms of development technology,lead-free soldering technology and the associated soldering agents have grown out of their 'infancy'. After 15 years, the principle of using lead-free solder in assembly production is clear and the processes are now well established. The phase of optimizing these processes has begun. With this process optimization, it is now also necessary to optimize the corresponding soldering agents. In particular, the requirements of modern selective soldering processes pose a challenge for flux development.

The ongoing miniaturization of components requires, among other things, a reduction in the grain size of SMD solder pastes or the wire cross-sections of solder wires. The finer the metal powder, the larger the total surface area of the powder in relation to its volume. This requires greater activation of the paste flux.

New technologies, such as the introduction of LEDs in vehicle and street lighting, have reignited the discussion about reducing soldering temperatures. Bismuth-based solder alloys represent a solution, but have properties that still need to be examined in detail. A more highly activated flux formulation is required here, as wetting with these solders is worse than with SAC solders.

In addition to activating the metallization of the components and the metal powder content of the SMD solder paste, the flux in SMD solder pastes also serves to adjust the viscosity and is therefore essential for the printability, dispensability and tackiness of the paste. This in turn would make it necessary to replace the active components with neutral 'fillers', which would have to behave in the same way as the activator mixture. Therefore, there is no flux-free SMD solder paste that is particularly suitable for a vacuum process in this sense.

Although it would be desirable to reduce the flux content or solids content in the individual soldering agents and the associated reduction in residues on the assembly, this should not be at the expense of soldering performance!

The development and optimization of soldering agents must be carried out in close cooperation with the soldering equipment manufacturers and the innovations in process technology. For the production planning of new electronic products, not only the performance of modern soldering systems, but also the properties of the solders and fluxes must be considered in combination.

Standards / Literature / Sources

DIN EN ISO 12224-1:1998 'Solid solder wires and flux-filled tubular solders - Specification and test methods - Part 1: Classification and requirements' EN ISO 9454-1:2016 'Fluxes for soft soldering - Classification and requirements - Part 1: Classification, marking and packaging' DIN EN ISO 9453:2014 'Soft solders - Chemical composition and forms of delivery' DIN EN ISO 9455-10:2013 ,Fluxes for soft soldering - Test methods - Part 10: Determination of flux effectiveness, spreading test' DIN EN 32513-1:2005 ,Soft solder pastes - Part 1: Composition, technical delivery conditions' DIN EN 61190-1-1:2003 ,Joining materials for electronic assemblies - Part 1-1: Requirements for soft solder fluxes for high quality joints in electronic assembly' DIN EN 61190-1-2:2014 ,Interconnection materials for electronic assemblies - Part 1-2: Requirements for solder paste for high quality interconnections in electronic assembly' DIN EN 61190-1-3:2015 ,Interconnection materials for electronic assemblies - Part 1-3: Requirements for electronic solders and for solid form solders with or without flux for soldering of electronic products' DIN EN 61189-5-3:2015 ,Test methods for electrical materials, printed circuit boards and other interconnection structures and assemblies - Part 5-3: General test methods for materials and assemblies - Solder paste for assembled printed circuit boards' DIN EN 61191-1:2015 'Electronic assemblies on printed circuit boards - Part 1: Generic specification - Requirements for soldered electrical and electronic assemblies using surface mount and related assembly techniques' IPC J-STD004 'Requirements for Soldering Fluxes'