The virtual event format MID Days was launched in February 2021. It is intended to facilitate the exchange of research activities between science and companies.

The new online format is characterized by its compactness in terms of time with good networking opportunities at the same time. This is because the presentations only last around 20 minutes, each followed by around 10 minutes of discussion to allow questions to be asked directly to the scientists. As the first event showed, this 'technical hour' provides a brief yet in-depth insight into the latest developments in research. And afterwards, there is the opportunity for extensive networking via a link. The new MID Day format allows institutes and companies to stay in touch even in times of coronavirus.

Two of the AiF-IGF projects currently running through the 3-D MID e. V. research association will be presented in each of the webinars by their scientific advisors. They are organized by 3-D MID Managing Director Philipp Bräuer. They are open to all interested parties and free of charge.

1st MID Day: Presentations on silver sintering

The first MID Day included presentations on the AgOn3D and LaDi-Print funding projects. The event was opened and moderated by Prof. Dr.-Ing. Jörg Franke, Chair of Manufacturing Automation and Production Systems (FAPS) at Friedrich-Alexander University Erlangen-Nuremberg. As the online event also had many foreign participants, the presentations and discussions were held in English.

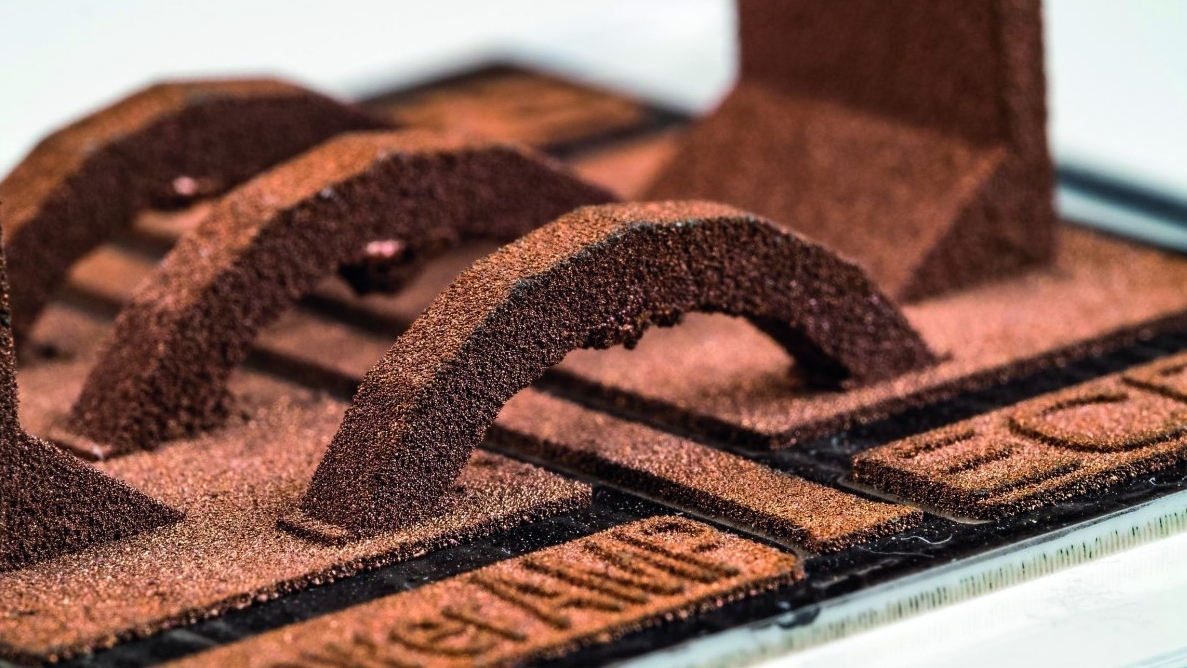

The first presentation was given by Alexander Hensel, FAPS, on the IGF project 20132 N - AgOn3D. The full title of the project is 'Silver sintered on 3D ceramic substrates for electronics in high temperature applications'. Alexander Hensel's project partner is Christian Schwarzer, Aschaffenburg University of Applied Sciences. Together they are investigating silver sintering on 3D ceramic substrates for electronics in high temperature applications. The aim is to use spatial ceramic circuit carriers in conjunction with silver sintering technology in order to extend the range of applications to higher temperatures and harsh environments. Alexander Hensel presented the concept of a power module for ambient temperatures of over 250 °C. The copper is applied in a plasma-based coating process. This is followed by a post-processing temperature treatment for deoxidization. Alexander Hensel discussed the optimization of the parameters and reported on the results achieved so far and the problems identified for silver sintering. Tests can be used to determine the optimum parameters for coating and tempering.

In the second presentation, Simone Neermann, FAPS, introduced the IGF project 20202 N - LaDi-Print. The full title of this project is 'Fast and flexible production of conductor structures for the production of large-area mechatronic components by laser-assisted direct printing'. The project is investigating the fast and flexible production of conductor structures for the production of large-area mechatronic components by laser-assisted direct printing. This allows electrical functions to be applied to existing components, further increasing the integration density and reducing the product weight. Simone Neermann explained that large-area here refers to MID parts with dimensions up to the meter range, such as armrests for motor vehicles. When producing such parts, there are still problems with sintering in the printed electronics process chain: the sintering time in particular is too long. One possible solution is laser sintering. For tests, silver nanoparticle and silver microparticle inks were applied to ABS and PC/ABS substrates using aerosol jet printing or, alternatively, dispensing. These layers were sintered using Yb:YAG fiber laser irradiation with a wavelength of 1070 nm and different parameters. Simone Neermann explained the results of the investigations to date. The laser writing speed is the most important parameter. With a favorable choice of parameters, a threefold higher conductivity (up to >20 MS/m) can be achieved. However, there are limits, as delamination results if the laser power is too high.

Further MID Days already planned

The dates for the upcoming MID Days in 2021 have already been set. They are planned:

- 2nd MID Day on May 12

- 3rd MID Day on August 11

- 4th MID Day on November 10

3-D MID e. V. will publish further details on these events in the near future.