Airborne pollutants and particles generated during production must be removed as effectively and efficiently as possible. This article explains what needs to be taken into account based on information from the supplier of extraction systems and filter technology ULT AG, Löbau.

The process of manufacturing electronic assemblies and devices involves a wide variety of procedures. The technologies used for assembling, soldering, bonding, gluing, marking, potting, pressing, screwing, separating, etc. have one thing in common: they generate airborne pollutants or particles that can have a significant impact on people, production equipment and products. If electronic assemblies become contaminated, this can lead to partial or even complete functional failure.

Guidance on what to aim for and how this can be monitored is provided by, for example

- TA Luft (Technical Instructions on Air Quality Control)

- VDA Volume 19 Part 1 Testing technical cleanliness - Particle contamination of functionally relevant automotive parts

- VDA Volume 19 Part 2 Technical cleanliness in assembly - environment, logistics, personnel and assembly equipment

- ZVEI guidelines on technical cleanliness in electrical engineering

Why vacuuming and filtering?

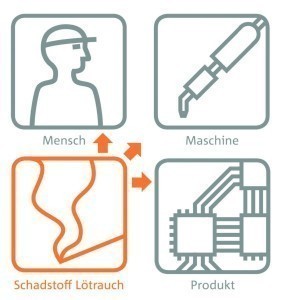

Airborne pollutants are a composition of particles of different sizes and compositions with different chemical and physical properties. The influence of soldering fumes on their environment is shown using the example of soldering fumes. Fig. 1: The threefold damaging effect of soldering fumes on people, machines and products

Fig. 1: The threefold damaging effect of soldering fumes on people, machines and products

Soldering fumes consist primarily of decomposition products from fluxes, soldering materials and residues from cleaning agents, which can combine to form sticky aerosols. These not only have a negative impact on the health of personnel, but can also form firmly adhering layers of dirt and thus contaminate production systems, which has a lasting negative impact on production quality. If, for example, manufactured electronic assemblies are contaminated with sticky dusts, this can lead to corrosion of the conductor paths, which can result in partial or even complete functional failure.

Airborne pollutants are generally classified according to particle size. This classification focuses primarily on the impact of emissions on the human organism. Airborne pollutants are not only differentiated according to whether they are harmful to the brain, nerves or respiratory tract, but also whether they are inhalable (E fraction) or alveolar (A fraction). There are legal limit values for this in accordance with DIN EN 481. These are 10 mg/m³ for the E fraction and 1.25 mg/m³ for the A fraction in accordance with TRGS (Technical Rules for Hazardous Substances) 900.

According to the statutory provisions of TA Luft (Technical Instructions on Air Quality Control), the maximum total dust mass concentration, including fine dust, is 20 mg/m³. However, this only applies to dusts that are harmless to health and does not include the so-called CMR substances (carcinogenic, mutagenic, toxic for reproduction).

Air pollutants and their optimal filtration

Airborne pollutants occur at various points in electronics production.

In soldering fumes: So-called soft soldering processes are used for the most part in the production process, including wave, reflow, vapor phase, laser or manual soldering. This produces a variety of hazardous substances, e.g. organic tin compounds, hydrogen chloride, formaldehyde, acetaldehyde, acrylaldehyde or butyraldehyde. The following soldering fume concentrations were determined during hand soldering:

- Concentration with leaded solder: approx. 1 mg/m³

- Concentration with lead-free solder: approx. 1.3 mg/m³

The proportion and quantities of these compounds depend on the composition of the solder and the soldering temperature.

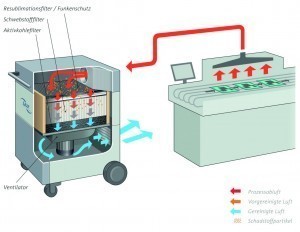

Due to the combination of pollutants in the solder fume, combination filters are used for optimum separation. These consist of resublimation filters, particle filters in several stages and adsorption filters.

In larger wave soldering systems, the exhaust air from the fluxer and solder wave is filtered separately. When using solvent-based fluxing agents, fans with Ex equipment are used to prevent explosions or fires. Fig. 2: Comparison of particle types and sizes

Fig. 2: Comparison of particle types and sizes

Gases and vapors: These are produced during printing, casting, painting, gluing and cleaning, among other things. Typical pollutants are isopropanol, toluene, acids, butanol or resins.

The relevant substance data is determined using the relevant safety data sheet. Based on the result, the type of filtration is determined, whereby in this case sorption technologies, i.e. adsorption using activated carbon or chemisorption using chemically modified adsorbents, are used. The safety data sheet also provides information on the explosion limits. If it is not safe to fall below the lower explosion limit, Ex fans must again be used in the extraction system.

Dusts: These are generated in electronics production, for example during cutting, milling, grinding, polishing or decanting. Typical pollutants are coarse dust, fine dust and odors. Dry dusts are usually separated using cartridge filter systems. The filter cartridges can be cleaned and therefore used over a relatively long period of time. All dusts must be tested for flammability before they are extracted and filtered, as Ex systems must be used in this case in order to comply with occupational health and safety and explosion protection regulations.

Laser smoke: This is mainly generated during marking, cutting, decoating or structuring. Typical pollutants include nanoscale particles as well as aerosols and gases.

During laser processing, a material transformation takes place through pyrolysis, oxidation, reduction or polymerization. This requires special filter combinations. In addition, the composition of the laser fumes is determined by the type of laser source and the energy input.

Due to the combination of pollutants in the laser fume, combination filters are mostly used. As with solder fume extraction, these consist of resublimation filters, particle filters in several stages and adsorption filters.

Due to the diversity of laser fumes, the filter geometries and their stages are adapted to the application. Cleanable filter systems are also used. The addition of filter aids increases the separation quality and thus the filtration performance. Fig. 3: Extraction system with combination filter for separating soldering fumes

Fig. 3: Extraction system with combination filter for separating soldering fumes

Capturing air pollutants

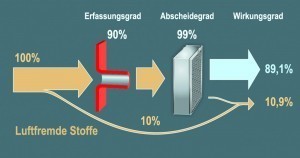

An important aspect of air purification is the collection of air pollutants. This is usually carried out using extraction arms, each with a mounted capture element. The size and type are determined by the pollutants themselves, their thermal properties and other air movement influences. Fig. 4: High capture and separation rates increase the air purification performance of a filter system

Fig. 4: High capture and separation rates increase the air purification performance of a filter system

The level of capture efficiency and separation efficiency are decisive for the efficiency and filtration performance of the respective extraction system.

The proximity to the emission source is of decisive importance - the closer, the better. Not only to capture the majority of all particles before they can spread, but also to minimize economic costs. There is a rule of thumb that double the distance between the emission source and the capture element requires at least four times the suction power of the extraction and filter system.

The use of the optimum capture element, extraction arm or extraction hose depends on the application itself. In production lines, extraction and filter systems are often integrated directly into processing systems, e.g. laser markers or soldering systems. The pollutants are therefore collected in the encapsulated system and primarily serve to protect the system itself and the product.

Different variants are available for manual workstations. For example, a filter unit can be used as a central extraction system. The respective workstations are equipped with capture elements that are connected to the system via pipes or hoses. The exhaust air flow is activated or deactivated via throttle valves.

Depending on the amount of pollutants produced, each individual manual workstation can also be equipped with an extraction system. Mobile systems are primarily used here, which are particularly suitable for changing workstations.

Individual design

Although many processes in electronics production are standardized, the variety of materials used and processed often requires an individual analysis of the pollutant situation. The use of different organic, inorganic or toxic substances through to the use of precious metals, the recycling of which must be taken into account when selecting filters, are just a few examples of the 'normal abnormal'. Standard solutions are no help here. The respective production situation must be assessed individually and an appropriate special solution designed.

In addition to the extraction and separation performance of a filter system, other parameters such as noise level, robustness and space requirements also come into play. Because even with clean air, employees do not want to be disturbed or hindered in their daily tasks.