In March, Seho launched a new digital event series that provides compact information on innovative technology, application expertise and the optimization of production processes. In particular, it shows how consistently high product quality and a sustainable reduction in production costs can be achieved at the same time.

The first Technology Trend Day in the new digital series was held by Seho Systems GmbH, Kreuzwertheim, together with Stannol GmbH & Co. The topic was water-based fluxes. Moderated by Heike Schlessmann, Seho, practical knowledge about their use was imparted. Speakers were Jens Gruse, Stannol, and Dr. Ronny Horn, Seho, who each gave presentations lasting around 40 minutes on the advantages of water-based fluxes, what needs to be considered when switching processes and how system technology can be implemented to avoid cycle time losses. Participants' questions were then answered by the experts in a discussion round.

Differences between alcohol-based and water-based

Example from the Stannol flux programInhis presentation entitled 'Water-based fluxes for wave and selective soldering - advantages of water-based fluxes', Jens Gruse discussed the differences between alcohol-based and water-based fluxes. The composition of the fluxes differs in the solvent and the activators and water-based fluxes do not contain rosin or resins. The classification and labeling according to J-STD-004B or ISO/IEC reflects this.

Example from the Stannol flux programInhis presentation entitled 'Water-based fluxes for wave and selective soldering - advantages of water-based fluxes', Jens Gruse discussed the differences between alcohol-based and water-based fluxes. The composition of the fluxes differs in the solvent and the activators and water-based fluxes do not contain rosin or resins. The classification and labeling according to J-STD-004B or ISO/IEC reflects this.

In SIR tests, water- and alcohol-based fluxes deliver comparable results. Jens Gruse presented comparative data and copper mirror test results of various flux examples. Application using a spray fluxer is also straightforward and produces similar results. However, semi-aqueous and fully aqueous fluxes require the preheating of the soldering systems to be optimized due to the higher evaporation temperature and heat requirement. For the water to begin to evaporate, temperatures 20 K to 30 K higher than for alcohol are required. And the PCB must be completely dry before it comes into contact with the solder wave in order to avoid solder bead formation. The soldering equipment should be tested for compatibility with water-based fluxes - iron parts can rust. Water-based fluxes are VOC-free, which is an advantage in view of increasing demands. There is also potential for cost savings. Given the current market situation and availability of IPA and ethanol, this amounts to around 18%. Added to this are the savings in transportation (no hazardous goods) and storage (no hazardous, flammable goods) as well as the (possible) 20 % to 50 % reduction in application quantity. The market share of water-based fluxes is currently around 10 %.

A problem for the soldering process?

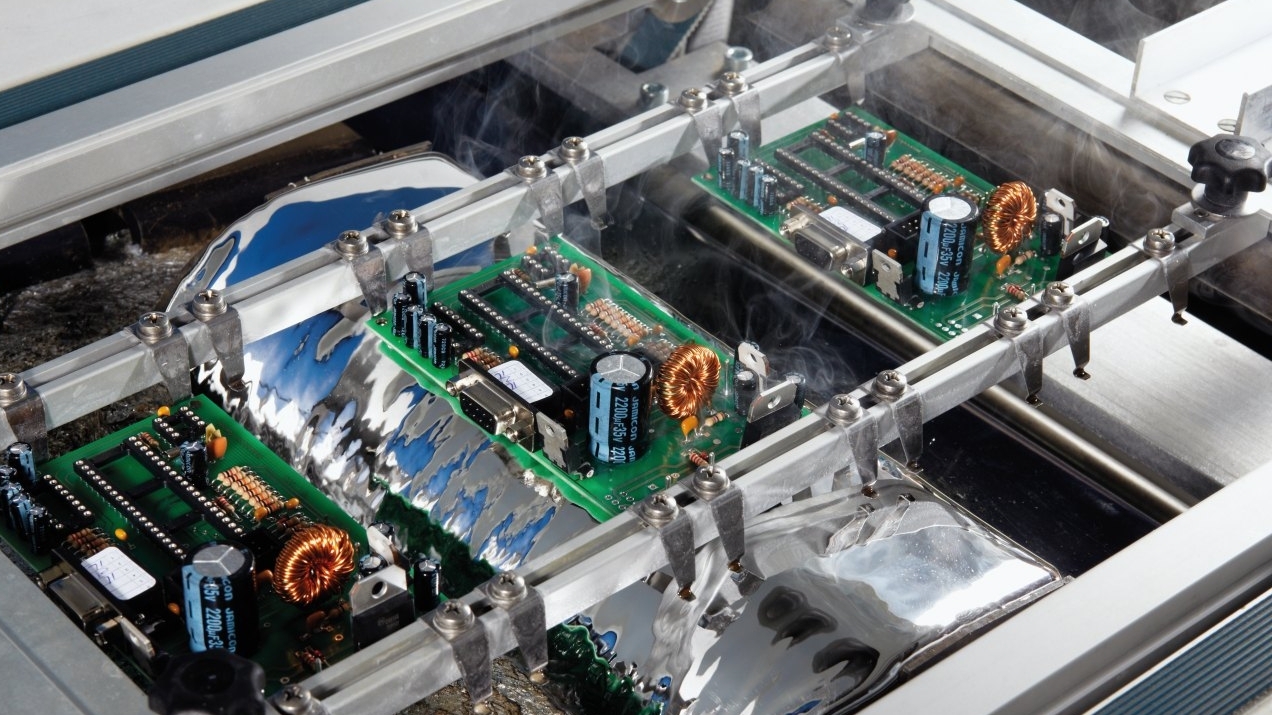

Dr. Horn addressed the question of whether water-based fluxes can be a problem for the soldering process. He presented the plasma fluxing process and the systems designed for it as well as their results as another possible flux application - a completely solvent-free alternative. This was followed by information and practical tips on how to switch the process from alcohol-based to water-based fluxes without losing cycle time, based on the higher energy requirement and longer time required for preheating. Possible starting points for existing equipment are the additional installation of a top side heater in the form of convection preheating modules or pulsar preheaters. The former ensure homogeneous heating of the assembly and support the evaporation process. The latter are characterized by a high energy input, which is ideal for high-mass products. It is also possible to convert from quartz or IR to Pulsar preheating, which results in a preheating output that is around 20 % higher in line with the increased demand.

A major advantage of Pulsar preheating is the high control speed, which enables virtually instantaneous switching between different products. Stand-by consumption can also be significantly reduced. 30 % to 50 % less energy consumption at medium to low utilization is possible. Further effects can be achieved by installing additional heating stations within the system or a separate preheating module upstream of the system, as Dr. Ronny Horn demonstrated using examples. A gradient-controlled, optimized preheating process can also be implemented by retrofitting pyrometers. Optional nitrogen preheating in the soldering area provides additional heat energy immediately before entering the solder wave.

Conclusion of the first Technology Trend Day

In general, all soldering systems are also suitable for processing water-based fluxes. A second flux system supports the gradual changeover and offers maximum process reliability. Cycle time losses can be avoided by installing additional units in the preheating area. An additional temperature sensor system helps to avoid unnecessary stress on the assemblies. Seho and Stannol offer support during the changeover. The Digital Technology Trend Day was a successful start to the series of digital events that Seho is planning for 2021. The event calendar will be gradually expanded to include other exciting topics. The second online event on the topic of sustainability and cost efficiency in wave soldering has already been scheduled.