How can a nitrogen atmosphere in convection soldering systems prevent soldering defects? Rehm Thermal Systems has investigated this question on the basis of typical error patterns.

The selected soldering atmosphere has a significant influence on the occurrence or avoidance of soldering defects. Typical defect patterns include solder beads/beading, voiding, whiskers, graping, head-in-pillow, wetting faults and tombstones. The tests were carried out on the convection soldering systems from Rehm's Vision series, which are designed as air or nitrogen systems.

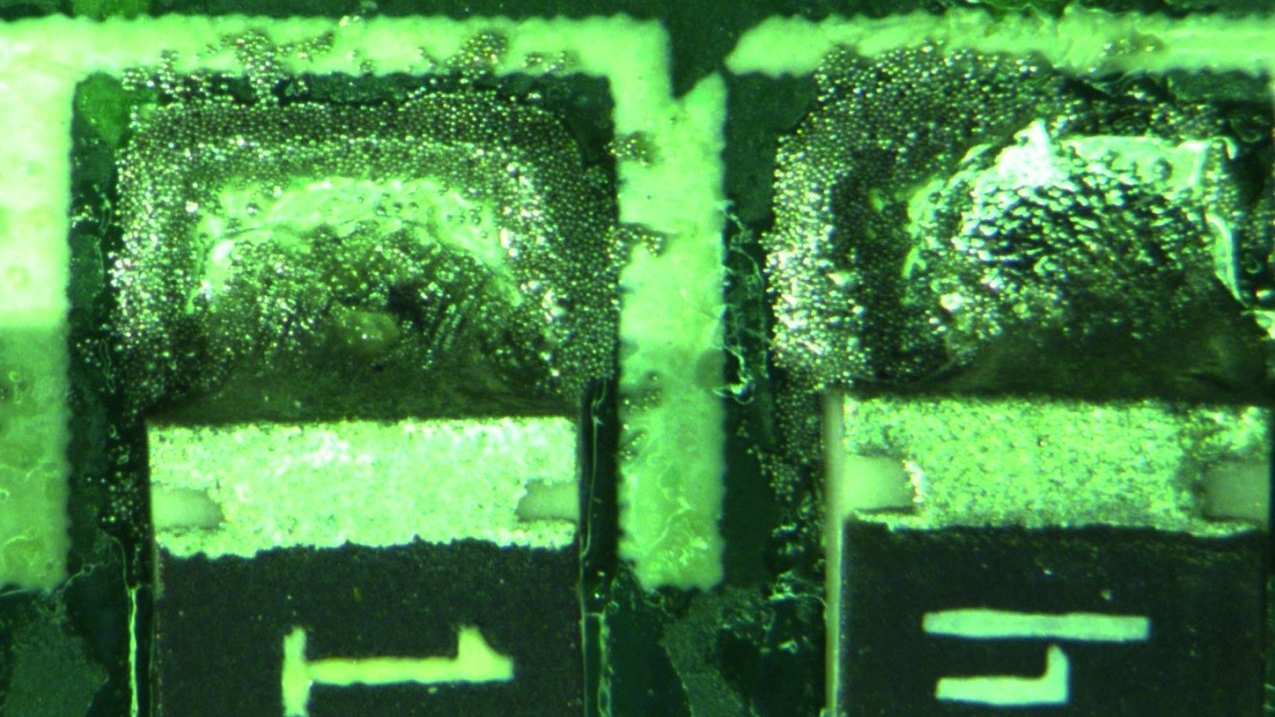

Solder beads / beading:

A common defect is solder beads on two-pole components, which is called beading in American. Beading is caused by solder grains from the solder paste that get under the component and are squeezed out of the gap under the chip during melting. All solder pastes tested were found to have less beading after reflow soldering under nitrogen. The reason for this is seen in the better and faster fusion of the individual solder grains of the paste into a uniform solder volume. As there is no oxygen in the solder atmosphere, there is no formation of oxide skins on the solder grain surface, which would hinder fusion. This reduces the likelihood of individual solder grains getting under the gap of the chip.

Voiding:

The reduced formation of pores, or voiding, in surface and QFN soldering is also attributed to better wetting. The fast-wetting solder can expel the gases produced during reflow soldering more efficiently from its liquid volume. However, these results cannot be generalized for all solder joints.

Graping:

In this soldering defect, the molten solder appears like a bunch of grapes, or 'grape' in English. Although flux properties are constantly being improved, classic properties such as cold and hot slump should not be neglected when creating reflow profiles. Not only the time over liquidus and rise gradients are decisive. Miniaturization also entails a smaller paste grain size. The smaller the grain diameters become, the more they have to be 'protected' from oxidation by the flux. If the protective flux has disappeared from the paste grain due to 'bleeding' in the preheating area (hot slump), it oxidizes and will then melt, but will no longer fuse with other paste parts. After solidification, the oxidized solder takes on the appearance of a bunch of grapes. The process window is enlarged by the inert nitrogen atmosphere, but the influence of the flux is not completely prevented.

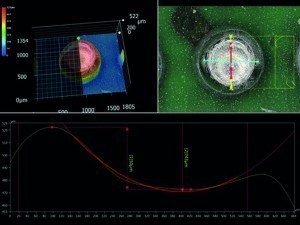

Head-in-Pillow (HiP):

The head-in-pillow or head-on-pillow effect is caused by an oxide layer on the BGA ball, which prevents the paste grains from fusing together. Typically, twisting and curvature of the BGA and/or the PCB causes the paste deposit to separate from the BGA ball. Analysis of a head-in-pillow BGA ball

Analysis of a head-in-pillow BGA ball

Due to the lack of flux activation, an oxide layer forms on the ball, which later prevents it from fusing with the paste depot, even though it is immersed in the remelted paste depot again. As the flux is used up at this point, the oxide layer can no longer be reduced and no connection is made.

Externally, it appears as if the ball is resting in a pillow (head-in-pillow, HiP) or on a pillow (head-on-pillow). If oxidation is prevented by an inert atmosphere (N2 or vapor phase) during separation, the paste deposit and ball can merge into one another. A low

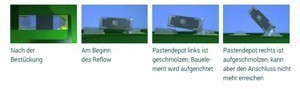

residual activity from the flux must still be present. Phases in the formation of a tombstone

Phases in the formation of a tombstone

Wetting disturbances:

The good wetting conditions under nitrogen generally lead to better spreading of the solder and prevent soldering defects due to wetting deficits of the soldering surfaces (IPC 610). This is well known, but the expected better soldering results are not always achieved. Chip soldering is characterized, among other things, by the shape of the realized meniscus. The height of the increased solder is a quality feature. Under a nitrogen atmosphere, the detected wetting height can be lower than under air. In other words, the non-wetted area (gap) increases. The reason for this is actually the better solder spreading under nitrogen. As the solder has to work against gravity to wet the component connection, the PCB pad to be wetted is favored; in addition, the sphere height is lower with greater spreading. This means that there is less solder available that can rise to the component connection.

Tombstones:

Tombstones are caused by differences in wetting times between the two sides of a two-pole component. If one of the solder joints melts before the other, the wetting forces and the surface tension of the liquid solder cause the component to rise. The second solder deposit, which melts with a time delay, then has no chance of wetting the second component connection. Under a nitrogen atmosphere, more tombstones are often observed after reflow soldering. This is again due to the improved wetting, which means that the wetting time difference between the two component connections is usually greater. However, the interactions with other influencing factors are also considerable in tombstoning.