In the course of development work to solve a problem, it sometimes happens that a solution is created that not only achieves the original goal, but also offers unexpected new advantages: The genesis of the JEAN-151 solder paste platform, which now includes 8 different alloys and 3 powder types.

Fig. 1: Solder paste depotItstarted with a research project that was launched with the aim of minimizing solder ball formation that occurs during the reflow soldering process when the solder is squeezed out at the edge of a surface mount component and does not flow back under the component as the process progresses.

Fig. 1: Solder paste depotItstarted with a research project that was launched with the aim of minimizing solder ball formation that occurs during the reflow soldering process when the solder is squeezed out at the edge of a surface mount component and does not flow back under the component as the process progresses.

The project not only solved the problem, but also led to the development of a versatile new flux platform with one of the broadest application spectrums in the industry. Before the flux formulation was developed, a completely new production process was developed for it. This was the only way to meet the high demands placed on the new flux, which had to be robust, particle-free, low-reaction and, above all, versatile. The result is impressive: The new JEAN-151 flux can currently be combined with eight different alloys and three powder sizes (T3, T4 and T5) without any changes. This makes JEAN-151 one of the most versatile flux platforms with one of the broadest application spectrums in the industry.

The original aim of the project was to improve contour stability, i.e. the ability of the solder paste to maintain its extruded shape and stickiness on the circuit board even at rising temperatures over a longer period of time(Fig. 1). If a paste does not have sufficient contour stability, it can collapse as reflow temperatures rise. A condition known as 'hot slump' which increases the risk of mid-chip solder balling.

Fig. 2: Solder ball topography of different alloysAnotherproject goal has been to extend the lifetime of the printed paste and the overall lifetime to achieve an improvement in the printing process. The flux plays a decisive and important role in the solder paste. It forms a homogeneous suspension with the solder powder, protects the powder from oxidation and should not be chemically reactive. Only in this way can the rheological properties, dynamic viscosity, contour stability and thus the thixotropy of the solder paste be guaranteed. It should be noted that the use of different alloys and powder types has an enormous influence on the thixotropy(Fig. 2).

Fig. 2: Solder ball topography of different alloysAnotherproject goal has been to extend the lifetime of the printed paste and the overall lifetime to achieve an improvement in the printing process. The flux plays a decisive and important role in the solder paste. It forms a homogeneous suspension with the solder powder, protects the powder from oxidation and should not be chemically reactive. Only in this way can the rheological properties, dynamic viscosity, contour stability and thus the thixotropy of the solder paste be guaranteed. It should be noted that the use of different alloys and powder types has an enormous influence on the thixotropy(Fig. 2).

In addition, good adhesion and temperature stability of the flux is required to enable sufficient activation up to the peak zone at the higher temperatures in the lead-free reflow soldering process. The combination of high- and low-melting resins in conjunction with higher-boiling solvents improves the 'hot slump' properties and thus achieves greater temperature stability.

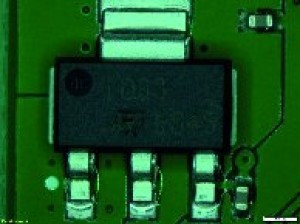

Fig. 3a: MELF with mid-chip solder ballsFirst, the silver-containing, lead-free standard alloy SAC305 (SnAg3.5Cu0.5) with a powder grain size of T4 (20 µm - 38 µm) was used. SAC305 has a melting range of 217 °C to 219 °C and is suitable for air, nitrogen and vapor phase applications. After passing all internal tests with SAC305 T4 by JEAN-151, which is classified as ROL0 according to J-STD-004, it has been shown that the decisive, desired research breakthrough has been achieved. Since then, extensive customer evaluations have been carried out at 19 different locations. The tests have resulted in more than 300 images, x-rays and reports, all of which confirm the effectiveness of the new system.

Fig. 3a: MELF with mid-chip solder ballsFirst, the silver-containing, lead-free standard alloy SAC305 (SnAg3.5Cu0.5) with a powder grain size of T4 (20 µm - 38 µm) was used. SAC305 has a melting range of 217 °C to 219 °C and is suitable for air, nitrogen and vapor phase applications. After passing all internal tests with SAC305 T4 by JEAN-151, which is classified as ROL0 according to J-STD-004, it has been shown that the decisive, desired research breakthrough has been achieved. Since then, extensive customer evaluations have been carried out at 19 different locations. The tests have resulted in more than 300 images, x-rays and reports, all of which confirm the effectiveness of the new system.

The solder paste exhibits stable and reproducible printing properties with excellent print definition and contour stability. In addition, it has 48 hours of adhesive strength, a guaranteed stencil life of 24 hours and a long, uncooled service life of 300 hours at 25 °C - 30 °C. In accordance with the IPC-A-610 standard, a void percentage of less than 30% and good wetting of all components, including edge QFNs, has been established in air, nitrogen and vapor phase soldering on numerous surfaces, such as ENIG, leaded and lead-free HASL, OSP, immersion Sn and immersion Ag.

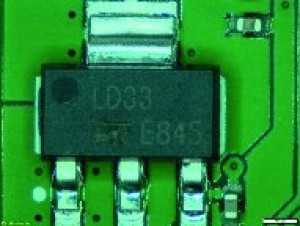

In a long-term test with 0402 components and smaller die openings, no solder balls were found in the center of the chip at one test location(Fig. 3a, 3b). In addition, the printed paste remained stable over a nine-hour working day and achieved a service life of one month. The flux residues are clear and can be covered or cleaned by conformal coating.

Even after the official market launch of JEAN-151 SAC305 T4, with a shelf life of six months, in 2019, both the Balver Zinn R&D team and the application engineers from technical support continued to work hard on the project. Since then, the 'baby' JEAN-151 SAC305 T4 has grown into a mature product portfolio with a shelf life of twelve months and eight different alloys.

Balver Zinn presented the complete portfolio at productronica 2021:

- JEAN-151 SAC305 T3, T4 and T5

- JEAN-151 SN100CV T4

- JEAN-151 SnIn6Ag3.5Bi0.5 T4

- JEAN-151 SCAN-Ge071 T3, T4

- JEAN-151 SN100C T3, T4

- JEAN-151 SAC0703 T4

- JEAN-151 SnPb36Ag2 T3, T4

- JEAN-151 SnPb37 T3, T4

Fig. 3b: MELF without mid-chip solder ballsThealloy SAC305 (SnAg3.0Cu0.5) has become the worldwide standard alloy for reflow soldering(Fig. 4a, 4b, 4c). It can be used for both high-tech and industrial applications. JEAN-151 is currently available in combination with SAC305 in powder sizes T3, T4 and T5. Work is already underway on T6.

Fig. 3b: MELF without mid-chip solder ballsThealloy SAC305 (SnAg3.0Cu0.5) has become the worldwide standard alloy for reflow soldering(Fig. 4a, 4b, 4c). It can be used for both high-tech and industrial applications. JEAN-151 is currently available in combination with SAC305 in powder sizes T3, T4 and T5. Work is already underway on T6.

SN100CV (SnBi1.5Cu0.7NiGe) is an alloy based on SN100C patented by Nihon Superior. In combination with JEAN-151, SN100CV is available with the powder T4. The addition of bismuth results in a 30% increase in strength. This makes SN100CV a high-strength, thermally stable alloy for high-tech and industrial applications.

SnIn6Ag3.5Bi0.5, also known as SABI alloy, is a highly reliable alloy for high-tech applications. The addition of 6 % indium gives the alloy excellent shear strength properties during the ageing of the solder joint and therefore better reliability compared to other alloys. In addition, SnIn6Ag3.5Bi0.5 is suitable for heat-sensitive components and substrates due to its low melting range between 202 °C - 210 °C.

SCAN-Ge071 (SnAg1 Cu0.7NiGe) is a nickel and germanium doped, silver-reduced alloy with a melting range of 217 °C to 225 °C. SCANGe071 is available with powder types T3 and T4 and produces matt solder joints with a fine-grained, homogeneous structure. The large melting range makes SCAN-Ge071 ideal for minimizing tombstone effects. SCAN-Ge071 is the ideal compromise between SAC305 and SAC0307 and can be used very well for industrial applications.

SN100C (SnCu0.7NiGe) is a nickel-stabilized, eutectic tin-copper alloy and is available with the powder types T3 and T4. The silver-free alloy is the most cost-effective, lead-free alloy that can be combined with JEAN-151. SN100C can be used for standard, industrial and high-tech applications.

SAC0307 (SnCu0.7Ag0.3), is a low-cost alloy with a low silver content and is available with type 4 powder for standard applications.

The tin-lead alloys SnPb37 and SnPb36Ag2 have been used in the electronics industry for decades. They have proven to be reliable and have excellent mechanical properties. Both alloys are available with powder type T3 and T4. Tin-lead solders continue to be used in aerospace and military applications.

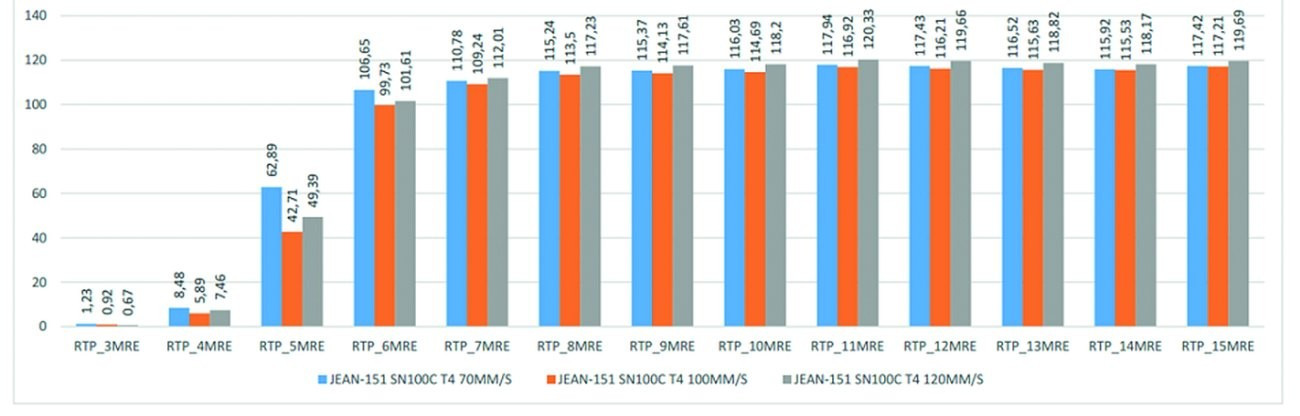

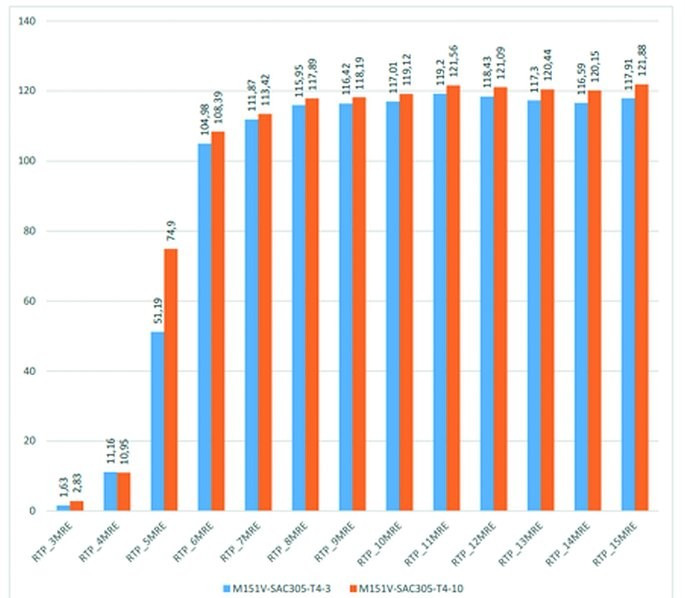

The sophisticated JEAN-151 flux formulation offers a wide process window in combination with the currently eight qualified alloys. Printing speeds from 30 mm/s to 120 mm/s are possible, regardless of the alloy or powder grain used. Higher speeds may require fine-tuning of the process. Even 6 mil (0.15 mm) stencil openings (6 MRE) are sufficiently filled with JEAN-151 SAC305 T4 solder paste at high printing speeds(Fig. 5).

Fig. 5: Solder deposit volumes: printing result on rectangular pads at different speeds

Fig. 5: Solder deposit volumes: printing result on rectangular pads at different speeds

During the shelf life extension tests of the JEAN-151 solder pastes, various batches were tested using SPI (solder paste inspection). The solder paste deposits of a 15-month-old JEAN-151 solder paste are shown below(Fig. 6). Even nine months after the expiry date, the JEAN-151 paste shows similar printing and soldering properties to those directly after production.

With this wide range of alloy variants available based on the unique, versatile JEAN-151 flux platform, users can rely on consistent, improved process performance in a variety of applications.

Fig. 6: Print properties with ageing

Fig. 6: Print properties with ageing

For the Balver Zinn Group, the development of a new flux, originally designed to solve the process problem of solder ball formation in the center of the chip, and its evolution to support the widest possible range of different alloys, illustrates the value of continuous research.

As new requirements are constantly being generated by the market, research continues in order to meet new challenges. As the processes for surface-mounted components evolve, so do the industries they support and supply.