Numerous technical and commercial advantages are driving the trend towards converting components from conventional soldering technology to press-fit technology. It is increasingly being used in the automotive industry, for example. IPTE has developed flexible solutions for press-fit processes.

Press-fit technology for printed circuit boards has its origins in space technology. The thermal requirements of satellites - especially high temperature differences, which have a detrimental effect on the solder joints - required new solutions for the connection technology in order to ensure the necessary high availability. The problem was solved by pressing the pins of the components into the circuit board. The new IPTE production cells in various sizes

The new IPTE production cells in various sizes

New solutions for connection technology

Press-fit technology also offers advantages in the automotive industry: Not only the thermal stresses on the PCBs in vehicles, but also the high mechanical stresses caused by vibrations are taken into account. In addition, the cost-intensive soldering process can be omitted (depending on the design, e.g. for flexible pins).

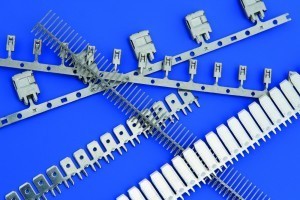

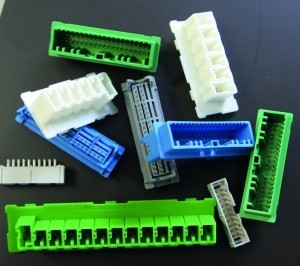

Components with press-fit contacts are typically multi-pin connectors as well as special electronic and electrical components. Until now, these had to be processed at manual workstations. This involved manually loading and unloading the PCBs and the components to be press-fitted. The manual press-fitting process itself was carried out using a servomotor-driven joining module.

Two standard products

IPTE has two standard machines in its range for the automation of such press-fit processes: IPTE FlexPresser and IPTE HSP II (HSP = High Speed Placer 2nd Generation). The FlexPresser is a machine for component press-fit technology. The HSP II is used to place press-fit contacts cut from contact strips into printed circuit boards with high precision and monitored placement force. Both machines are versatile and can be used for almost all customer applications.  Camera in the FlexPresser for pin check

Camera in the FlexPresser for pin check

When developing both machines, it was of fundamental importance to master the sometimes very high press-in forces. IPTE benefited from its many years of experience in the field of THT assembly and press-fit technology.

The FlexPresser is based on a cell with a rear feeder bench, which is extremely versatile when it comes to component feeding. A three-part belt segment for PCB transport, highly dynamic linear motors for moving the setting unit and a PCB support for absorbing the joining forces are just the most important highlights of this machine. The cell design has been adapted so that high press-in forces of up to 7000 newtons can be achieved.

New production cells

The FlexPresser and HSP II machines have been realized with the concept of the new IPTE production cell, the High Dynamic Cell. In addition to the focus on the requirements of Industry 4.0, a new visual appearance and the optimized arrangement of the machine components, the new generation of production cells also increases the standardization of the so-called standard machines. The High Dynamic Cell will also be used in IPTE depaneling machines. The expansion to the entire product range is being successively driven forward.

The High Dynamic Cell series with a height of two meters, three widths (1 m, 1.5 m and 2 m) and three depths (1.5 m, 1.7 m, 2 m) is scalable depending on the application and customer requirements. The cells have a modular design with high rigidity. In addition to standard processes, such as dispensing, milling or assembly, many additional processes can also be integrated into the production cells. Another feature is the optimized arrangement of the machine components for improved user-friendliness and accessibility. This significantly improves the handling of the machines during production changeover and servicing. The use of more transparent housing parts has resulted in cells that allow a much better view of the process sequence than the previous design. Last but not least, the transportability of the cells has also been significantly simplified. Sturdy eyelets on the top for cranes and defined holders for forklift trucks make handling easier.