What happens if the components required for assembly are not available on time due to economic crises? In addition to deadlines, costs are a decisive factor. For example, the production of a circuit board can become disproportionately expensive due to the use of a special alloy.

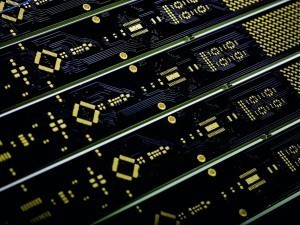

To ensure that no time is lost on the way from component procurement to assembly of the end product, wtronic - electronic production GmbH relies on an approach with coordinated supply chains and a close-knit network of material suppliers in Central Europe. The electronics expert accompanies the customer from material procurement to assembly and final assembly.  The choice of material influences the overall costs. For example, the circuit board is ten percent more expensive if it has a gold-plated instead of a tin-plated surfaceThisalso includes consulting services on cost-efficient design or material selection. Thanks to a special production and logistics structure, the company can work particularly flexibly and produce small to medium quantities of various types at short notice without delay. The high quality standards are ensured by automated multiple inspections and spot checks by employees.

The choice of material influences the overall costs. For example, the circuit board is ten percent more expensive if it has a gold-plated instead of a tin-plated surfaceThisalso includes consulting services on cost-efficient design or material selection. Thanks to a special production and logistics structure, the company can work particularly flexibly and produce small to medium quantities of various types at short notice without delay. The high quality standards are ensured by automated multiple inspections and spot checks by employees.

"For many manufacturers, the production chains for electronic products consist of a complex interplay between developers, buyers, suppliers and logistics providers," reports Christian Walchhofer, owner and managing director of the family business wtronic GmbH. "If there is a delay or error at one point, the success of the entire order is at risk." In particular, if the delivery date or quantity cannot be met due to a material shortage, subsequent costs or even the cancellation of an order are likely. In addition, the alloy, material and production process influence the price to varying degrees. For example, the use of a cheaper process is not necessarily detrimental to quality. However, in order to achieve the highest possible quality without driving up delivery times and costs, the company based in Völkermarkt, Austria, uses a particularly agile company structure that enables the PCB and assembly expert to process orders flexibly. In addition to an overarching customer service department, which has access to all aspects of the order from material procurement to assembly, the company relies on regional supply chains and a close-knit partner network of suppliers. This means that short-term market fluctuations or crises can be cushioned and dependence on overseas partners can be avoided. The know-how acquired over many years accompanies the entire value chain, from the selection of the right material in 'real-time' organized purchasing to precise assembly.

Competence Center advises from the specifications to series production

"At the heart of every order is a single contact person from the Competence Center, who has an overview of all the relevant stages. This person takes care of everything from order placement to delivery, including material procurement and production planning," explains Walchhofer. The employees of the Competence Center act as an interface and pool the know-how of the various company divisions in order to incorporate it into the respective order. In this way, wtronic is able to suggest an alternative manufacturer for the components after receiving the order parameters, for example, to adapt the layout or design of the circuit board or to use a different procedure for assembly. This can reduce the general component and process costs or ensure an advantageous choice of materials. This advice extends from the specification sheet and circuit design through to series production.

The profound relationship between circuit board properties and costs is reflected in a supporting app, which the customer can use to define their own circuit board and change individual components in order to check the impact on the calculation. For example, if the PCB has a gold-plated surface instead of a tin-plated one, the price is already 10% higher. "This service gives a better understanding of the scale and dimension of the finished PCB. There are specific selection options for the surface type, coating or base material, so that alternatives can be calculated in advance of an order," says Walchhofer.