In a joint project, researchers from the King Abdullah University of Science and Technology KAUST and the Fraunhofer Institute for Solar Energy Systems ISE have replaced the rotational coating step in the production of perovskite silicon tandem solar cells with a combination of vapor deposition and blade coating. The perovskite solar cells are deposited on silicon bottom cells. In this way, the tandem solar cells achieve efficiencies close to 28%. At the same time, the development paves the way for industrial production of these solar cells.

Even though perovskite silicon solar cells with high efficiencies of over 33% in the laboratory are currently giving the PV industry cause for optimism, their production on a large scale remains a challenge. "The successful application of the perovskite top cell to the silicon bottom cell using scalable technologies was a breakthrough for us," says Oussama Erraji, PhD student and project manager at Fraunhofer ISE. "In a two-stage hybrid process, the inorganic perovskite materials are first vapor-deposited and then the organic perovskites are applied using blade coating. This makes the process suitable for production on an industrial scale."

The scientists demonstrated fully structured perovskite-silicon tandem solar cells with open-circuit voltages of over 1900 millivolts and efficiencies of 27.8%. Furthermore, they found that unlike single-stage coated perovskites, the coating speed in the hybrid evaporation/blade coating process has no influence on the perovskite thickness, but correlates with the perovskite conversion rate, which was crucial for optimizing the absorber.

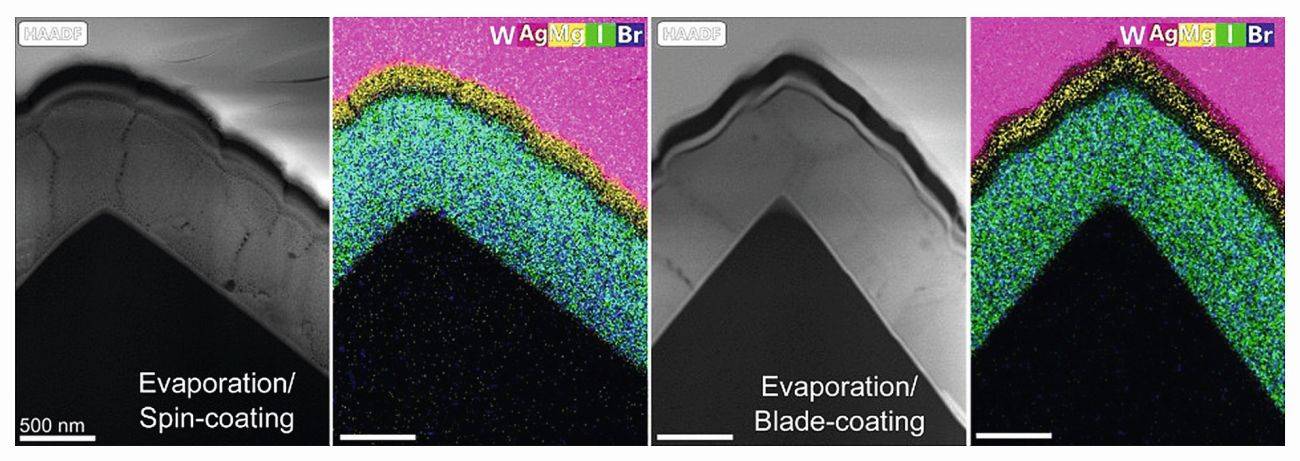

RTEM images of perovskite-silicon tandem solar cells produced by vapor deposition/spin coating or vapor deposition/blade coating - (Photos: Fraunhofer ISE)

RTEM images of perovskite-silicon tandem solar cells produced by vapor deposition/spin coating or vapor deposition/blade coating - (Photos: Fraunhofer ISE)

With this study, the researchers at Fraunhofer ISE are building on their extensive experience with the hybrid process, which combines evaporation with a wet-chemical process step. While the spin coating process was used for the wet chemical step in the past, they have now been able to transfer their experience to the more scalable blade coating for the second step.

Many perovskite research groups, including KAUST and Fraunhofer ISE, are investigating ways to bring perovskite silicon tandem solar cells into mass production. To date, perovskite silicon solar cells have mostly been produced using the spin-coating process. However, it is not suitable for large-scale production. "We also assume that the findings on the dynamics of blade coating can be transferred to slot die coating, which is even better suited for scaling," adds Dr. Juliane Borchert, Group Leader Perovskite Materials and Interfaces at Fraunhofer ISE.

Silicon solar cells can convert a maximum of 29.4 % of sunlight into electricity. The photovoltaic industry has almost reached this physical limit. In order to further increase the efficiency of solar cells, solar researchers around the world are turning to tandem photovoltaics, in particular perovskite silicon tandem solar cells. By combining two or more sub-cells made of different materials, a larger spectrum of sunlight can be utilized. While the silicon solar cell primarily converts the red portion of sunlight into electricity efficiently, the perovskite sub-cell above it can make better use of the blue portion of the light.