The measures in the economic stimulus package are intended to boost the economy, which has been badly hit by the coronavirus crisis, and also benefit the climate. A whopping 9 billion euros will be made available for the hydrogen program to promote the production, storage and use of hydrogen.

The most climate-friendly option would be to use only green hydrogen, which is produced by electrolyzing water with electricity from renewable sources. However, this is still far too expensive and energy-intensive. This is why hydrogen production using electricity generated in off-shore wind turbines is being promoted. As part of the national hydrogen strategy, funds are also being made available to set up an industrial photovoltaic plant in Morocco to supply electricity for electrolysis.

Nevertheless, the fossil energy source natural gas will still be needed in the future, especially to meet the growing demand for hydrogen. In order to meet the goal ofreducing CO2 emissions, theCO2 released during the steam reforming process is to be captured and stored. This still requires research in the field of CCS (Carbon Capture and Storage) technology.

Research projects funded by the German government in the past have shown that although hydrogen can be used in many sectors of the economy, it is very difficult to operate. However,CO2 emissions could be significantly reduced in steel and cement production in particular. Incentives are therefore needed to invest now in expensive butlower-CO2 technologies. Engineers at leading companies and research institutes were already working on fuel cell technology in the early 1990s. The first trains and buses are now running on fuel cells on a trial basis. Further research has focused on the production of so-called e-fuels from hydrogen andCO2 or methane. If e-fuels were used, the existing filling station network and tried-and-tested combustion engines could continue to be used. These examples show how versatile hydrogen can be.

The hydrogen strategy will hopefully help the automotive industry and suppliers to find answers to the question of the most cost-effective drive system - whether electric motor, hydrogen fuel cell and electric motor or combustion engine - that take environmental protection and profitability into account.

Breaking new ground with hydrogen Increasing energy efficiency in an electroplating company (Part 4)

3.2.3 Vacuum evaporator

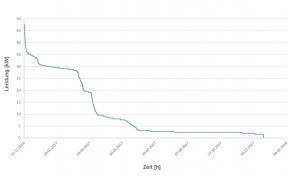

![Abb. 18: Leistungsbedarf des Vakuum-Verdampfers 2017 [IB Potthoff] Abb. 18: Leistungsbedarf des Vakuum-Verdampfers 2017 [IB Potthoff]](/images/stories/Abo-2020-07/thumbnails/thumb_ET_7-20_Giglia4_Abb18.jpg) Fig. 18: Power requirement of the vacuum evaporator 2017 [IB Potthoff]A vacuum evaporator is installed to reduce the wastewater flow (e.g. water containing chromium) and thus the disposal costs. The distillate and the concentrate (e.g. chromic acid) are fed back into the production process.

Fig. 18: Power requirement of the vacuum evaporator 2017 [IB Potthoff]A vacuum evaporator is installed to reduce the wastewater flow (e.g. water containing chromium) and thus the disposal costs. The distillate and the concentrate (e.g. chromic acid) are fed back into the production process.

The electrical drive of the vacuum evaporator is ageing and needs to be replaced.

The evaluation of the electrical power requirement of the vacuum evaporator in 2017 is shown in Figure 18.

Figure 18 shows that a base load of 2 kW is called up continuously. It also shows that the compressor has two stages. The first stage has an electrical output of between 15 kW and 20 kW.  Fig. 19: Ordered annual duration curve of the vacuum evaporatorThesecond stage has an electrical output of between 30 kW and 50 kW. Figure 18 also shows that the power consumption of the vacuum process is lower in the months of November and December. This could indicate changed production conditions.

Fig. 19: Ordered annual duration curve of the vacuum evaporatorThesecond stage has an electrical output of between 30 kW and 50 kW. Figure 18 also shows that the power consumption of the vacuum process is lower in the months of November and December. This could indicate changed production conditions.

Figure 19 shows the ordered annual duration curve of the electrical power

demand of the vacuum evaporator. It can be seen that the vacuum evaporator is operated in idle mode from 4200 h/a.

Table 11 lists the electrical data of the vacuum evaporator.

listed.

|

Designation |

Unit |

Unit Value |

|

Power consumption |

kWh/a |

96 122 |

|

Maximum load |

kWh |

51 |

|

Full load hours |

h/a |

1885 |

4 Measures to save energy and costs and to reduce

CO2 emissions

Based on the previous analysis of the current situation, the following measures for saving energy and costs and reducingCO2 emissions in the electroplating company are presented.

4.1 Measures on the exhaust air systems

As already mentioned above, the following measures are described here

- Partial covering of the baths

- Heat recovery with a circulation system (KVS system)

- Increasing the efficiency of the electric fan drives

are evaluated.

4.1.1 Partial coverage of the baths

According to the electroplating company, it is possible to partially cover the baths. For this purpose, the pool surface is provided with a partial cover, which is removed before the bath is loaded. The lateral slot extraction system must be adapted to the baths for this purpose. The exhaust air volume flow can be reduced by approx. 40 percent by reducing the bath surface.

Due to the reduction in the exhaust air volume flow, the heat dissipation from the production hall and the electrical energy requirement of the exhaust air fans are reduced.

Table 12 shows the reduced air volume flow and the electrical power of the bathroom fans:

|

Designation |

Volume flow with partial cover |

Electrical power with partial cover |

Electrical work with partial cover |

|

Volume flow area 1 (bath 1) |

6000 |

2,7 |

13 300 |

|

Volume flow bath 2, 3, 4 |

7200 |

4,6 |

24 615 |

|

Bath volume flow 5 |

3600 |

1,0 |

3 861 |

|

Flow rate bath 6 and nickel plating |

3600 |

1,0 |

7956 |

|

Designation |

Differential volume flow |

Saved heat output |

Saved heat output |

|

Volume flow area 1 (bath 1) |

4000 |

18 |

88 668 |

|

Volume flow bath 2, 3, 4 |

4800 |

21,6 |

115 582 |

|

Bath volume flow 5 |

2400 |

10,8 |

41 699 |

|

Flow rate bath 6 and nickel plating |

2400 |

10,8 |

85 925 |

The electrical output "with partial cover" listed in Table 12 was determined using equation <2> .

Table 13 shows the reduction in heat loss during the heating period due to the reduction in the volume flow rate.

The following approaches were taken into account when calculating the saved heat output:

- Specific water vapor output: 2.5 l/h -m2

- Bath temperature: 50 °C

- Internal hall temperature: 20 °C

- Reduced heat loss: 4.5 W/m3 - h

The main components of the existing exhaust air systems are reinstalled in the new production hall. It should be noted that the permissible pressure loss of the fans is taken into account when designing the air ducts, so that the efficiency measures determined above can be considered realistic.

4.1.2 Heat recovery with a circulation system (KVS system)

As described above, there is no corresponding supply air system for the exhaust air systems. It is intended to install a supply air system in the new production hall.

The advantages are

- Utilization of waste heat (heat recovery)

- Supply of conditioned supply air to the workplaces and

- Avoidance of draughts.

The new supply air system and the reinstalled exhaust air systems are to be equipped with a heat recovery system (HRS). The installation of the heat exchanger in the exhaust air duct is planned after the respective central scrubber.

The energy recovered is fed to the supply air system, also with a heat exchanger. A water-glycol mixture is used as the circulation medium. Furthermore, the reduced volume flow with partial coverage of the exhaust air systems is taken into account when evaluating the energy saving potential.

Table 14 shows the savings potential of the heat recovery system over the year.

This results in a savings potential of approx. 293,925 kWh/a.

The following approaches were taken into account in the calculation:

Primary side of the exhaust air heat exchanger:

- Temperature/rel. Humidity air inlet: 18 °C/90 %

- Temperature air outlet: 15 °C/90 %

Primary side of the fresh air heat exchanger:

- Mean annual outdoor air temperature/rel. humidity air inlet: 9 °C/25 %

- Air outlet temperature: 17 °C/10 %

- Enthalpy difference: 8 KJ/kg

- ήWRG: 27 %

- Total pressure loss on the air side: 800 Pa

|

Designation |

Heat recovery volume flow (with partial cover) |

Heat recovery heat output |

Heat recovery heat work |

|

Volume flow area 1 (bathroom 1) |

6000 |

16 |

78 816 |

|

Volume flow bath 2, 3, 4 |

7200 |

19 |

101 669 |

|

Bathroom volume flow 5 |

3600 |

9,6 |

37 066 |

|

Volume flow rate bath 6 and nickel plating |

3600 |

9,6 |

76 374 |

Table 15 shows the additional electrical costs of the heat recovery system due to the additional air-side pressure losses over the year. The following approaches were taken into account in the calculation:

- Pressure loss on the air side: 800 Pa

- ήFan: 60 %

When determining the air-side pressure losses, components such as the heat exchangers, the droplet separator and the cleaning system, as well as the electrical requirement for the circulation pump of 50 W were taken into account.

This results in additional electrical costs of approx. 40,647 kWh/a.

According to an initial, rough cost estimate, the static capital payback period is approx. 6.5 years.

|

Designation |

Heat recovery volume flow (with partial cover) |

Heat recovery electr. output kW |

Heat recovery electr. work kWh/a |

|

Volume flow area 1 (bath 1) |

6000 |

2,2 |

10 837 |

|

Volume flow bath 2, 3, 4 |

7200 |

2,7 |

14 448 |

|

Bath volume flow 5 |

3600 |

1,3 |

5 019 |

|

Volume flow rate bath 6 and nickel plating |

3600 |

1,3 |

10 343 |

4.1.3 Increasing the efficiency of the electric fan drives

Another measure relating to the exhaust air systems is the replacement of the electric motors on the fans. As the supply air system is being newly installed, we assume that the electric fan drives comply with the current efficiency standard.

Internationally applicable efficiency classes are defined in DIN EN 60034-30-1. From January 1, 2017, electric motors that are put into operation and have a drive power of > 0.75 kW must have at least efficiency class IE3. The energy saving potential is determined from the difference between the electrical efficiency in the actual and target state in Table 16.

The efficiency of the electric drives was taken from the rating plates, whereby the electrical work with partial coverage is taken into account in accordance with Table 12.

The use of the efficient electric drive results in savings of approx. 7234 kWh/a.

According to a rough cost estimate, the static capital payback period is approx. 7 years on average.

4.2 Measures on the vacuum evaporator

The electroplating company also intends to install the existing vacuum evaporator system in the new production hall.

The existing vacuum evaporator system is suitable for future operation in terms of process technology, and consideration is being given to replacing the main electric drive with an efficient one of the same size.

|

Designation |

Hall 1 fan |

Bathroom fan 2,3,4 |

Bathroom fan 5 |

Bathroom fan 6 and nickel plating |

|

Actual efficiency [%] |

74 |

75,5 |

75,5 |

75,5 |

|

Efficiency target [%] |

91,2 |

89,1 |

89,1 |

89,1 |

|

Actual consumption [kWh/a] |

13 300 |

24 615 |

3861 |

7956 |

|

Consumption target [kWh/a] |

11 012 |

21 267 |

3336 |

6874 |

|

Difference consumption [kWh/a] |

2279 |

3.348 |

525 |

1082 |

The electrical efficiency and the electrical output of 55 kW were taken from the rating plate. The electrical output was confirmed with the data listed in Table 11. The calculation of the electrical savings potential is contained in Table 17.

| Designation | Main electric drive Vacuum evaporator |

| Actual efficiency [%] | 79,5 |

| Efficiency target [%] | 94,6 |

| Actual consumption [kWh/a] | 96122 |

| Consumption target [kWh/a] | 81607 |

| Difference in consumption [kWh/a] | 14514 |

The use of an efficient electric drive results in savings of 14,514 kWh/a.

The rough cost estimate results in a static capital payback period of approx. 4.5 years. -to be continued