Mercury, cadmium and lead: these heavy metals are actually severely limited in modern batteries, but they are repeatedly found in excessive doses in these practical energy sources. Official bodies therefore feel compelled to carry out more checks. The basis for this is provided by the Swiss Empa, which is developing a special control method.

Viewed neutrally, batteries have many disadvantages. They are expensive, they run out quickly, they only supply direct current (apart from a few special designs) and they also make a mess. Nevertheless, we can no longer imagine our lives without them as energy storage devices.

Whether in industry, in the military, in the mobility sector or in private households: in many areas they fulfill their tasks as starter batteries, as a backup in industry, in consumer goods such as toys, watches, radios, laptops, cell phones and flashlights. But they are also used in medical applications such as hearing aids, pacemakers and measuring devices.

The demand for batteries - which also include rechargeable batteries - is huge. Due to the extreme demand for the raw materials used to store electricity, these are already becoming scarce and correspondingly more expensive. Another raw material killer is the increasing number of electrically powered vehicles, boats and even airplanes. Intensive research is therefore being carried out to replace scarce or even rare materials with more common ones.

Ingredients of certain batteries such as cadmium or lead are harmful to health or even toxic

In addition, some ingredients of certain batteries, such as cadmium or lead, are harmful or even toxic to health. Here too, scientists are looking for unproblematic substitutes. And there are indeed promising research approaches to further improve the sustainability of batteries.

Although many widely used battery types - such as lithium-ion batteries - are already available on the market today without heavy metals, there are still old battery types with heavy metals. In Switzerland, for example, a wide variety of battery models are sold - mainly by large distributors. They differ, for example, in the materials used. Many are based on zinc-manganese or lithium-ion, both of which do not contain heavy metals. In the EU and countries close to the EU, such as Switzerland and Norway, the trade and sale of batteries containing mercury (Hg) or cadmium (Cd) is severely restricted. There is a limit value of 5 mg/kg for mercury in batteries and 20 mg/kg for cadmium. Lead must be declared on the battery or its packaging if it exceeds 40 mg/kg by mass.

But what use are regulations if it is not possible to check whether they are being complied with? Until recently, there was hardly any way to check compliance; there was simply no reliable and recognized method to precisely determine the elements mentioned in batteries.

Innovative analytics solves difficult chemical tasks

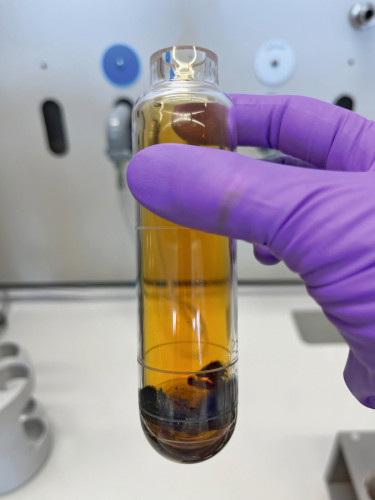

A team from Empa's "Advanced Analytical Technologies" research department led by chemist Renato Figi therefore set about developing a method for analyzing the heavy metals mercury, lead and cadmium in various types of batteries on behalf of the Swiss Federal Office for the Environment (FOEN). A task that turned out to be far from simple. Unlike many objects, which can simply be shredded to analyze their contents and then the chemical elements in a solution can be analyzed by various spectrometers, batteries cannot simply be shredded. Even the attempt to open a storage battery can be quite dangerous. Time and again, there have been accidents in which batteries have exploded as a result of such manipulations.

After discharging and forcibly opening the battery, the observer is presented with a very simple picture of the inner workings. However, the composition of the chemicals used is often complex

After discharging and forcibly opening the battery, the observer is presented with a very simple picture of the inner workings. However, the composition of the chemicals used is often complex

Claudia Schreiner was not allowed to expose herself to this danger in the Empa laboratory. She therefore turned to an Empa colleague, a specialist in the field of batteries and their dangers. Marcel Held from the "Transport at Nanoscale Interfaces" department advised her first and foremost to carefully discharge all the batteries to be examined. Only then should one dare to look inside a battery.

|

Sales |

Collection rate |

Collection rate |

Collection rate |

Recycling |

|

|

Portable batteries |

65 368 t |

26 434 t |

45,60% |

||

|

Lead-acid |

2815 t |

. /. |

. /. |

81,60% |

150 943 t |

|

Ni-Cd |

162 t |

. /. |

. /. |

79,50% |

1048 t |

|

Other |

62 391 |

. /. |

. /. |

76,20% |

29 620 t |

But not all batteries are the same. There are countless different designs. Even if one battery looks like a twin on the outside, the internal structure can differ significantly. And something else emerged during the work: Potentially hazardous substances are not always located where you would expect them to be. They may well be in the seemingly harmless casing.

Reliable analysis even at trace levels

But the painstaking work in the laboratory has paid off: Empa's innovative method can now reliably determine the ingredients of common batteries at trace levels. For analysis, the batteries must first be discharged and then separated. The various components of the different battery types are sorted and then dissolved by boiling an acid mixture under pressure. In this way, the heavy metals are dissolved and can be determined spectroscopically.

Only small button cells - due to their small size - can be dissolved as a whole for analysis in the spectrometer after discharging in acid. All other battery cells and large button cells must be carefully - i.e. laboriously - disassembled and crushed

Only small button cells - due to their small size - can be dissolved as a whole for analysis in the spectrometer after discharging in acid. All other battery cells and large button cells must be carefully - i.e. laboriously - disassembled and crushed

The method now makes it possible to monitor compliance with existing regulations. It is being used as part of a broad-based FOEN campaign. To ensure that the random samples of the different battery types provide as representative a picture as possible, around 80 different batteries will be selected over the course of this year and then analyzed at Empa. The Zurich cantonal laboratory is in charge of the campaign. The results are expected in 2024.

All photos: Empa