Explosion protection in companies with explosive solvents and dusts is usually formal at best. Personal experience with explosions usually remains in the dark, especially in the absence of major damage. But even the causes of major explosion accidents are all too often not made public, to the detriment of the many companies that have suffered similar disasters later on.

For insurance reasons and for fear of legal consequences and reputational damage, the causes of explosions usually remain hidden despite extensive efforts. Explosion protection is more than just complying with legal and sub-legal regulations: it also involves learning from incidents, sharing relevant experience and extensive training, especially in the area of preventive explosion protection.

3 Statutory explosion protection regulations

In addition to European regulations and national laws, there are also a number of sub-legal regulations, such as international standards or European and German standards.

The explosion protection document, which used to be part of the Ordinance on Industrial Safety and Health, has been part of the Ordinance on Hazardous Substances since 2015. It must be taken into account when working with explosive substances, mixtures and products in hazardous areas as part of the risk assessment.

3.1 European regulations

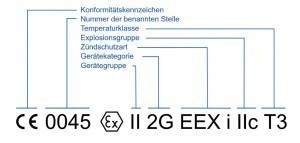

Fig. 10: Marking of devices for operation in potentially explosive atmospheres in accordance with the ATEX Product Directive 2014/34/EUTheEuropean Commission in Brussels has drawn up "ATEX Directives" for both plant manufacturers [19] and producers [20], which guarantee basic safety and health requirements in explosion protection in a harmonized and updated manner. ATEX is derived from the French abbreviation for "ATmosphères Explosibles" (explosive atmospheres).

Equipment for operation in potentially explosive atmospheres must be specially marked by equipment manufacturers (Fig. 10) [19].

The ATEX directive for system operators is the central element for the risk assessment.

Employers and their managers are obliged to assess potential hazards before using equipment, work equipment and protective systems in potentially explosive atmospheres and to derive necessary and suitable protective measures from this.

This is a very responsible task and not always easy to carry out in an appropriate form. The risk assessment may only be carried out by competent persons! If these persons are not available in the company, external support must be requested. The employers' liability insurance associations have competent safety engineers and can provide advice.

Decisions laid down in the catalog of protective measures must be implemented appropriately and regularly checked for effectiveness. Inspection content, inspection intervals and the qualifications of the inspectors must be defined in the risk assessment. The protective measures taken must at least correspond to the state of the art. Risk assessments must be reviewed regularly, especially in the event of significant changes.

The provisions of the European ATEX directives are limited to minimum requirements that must be implemented by the member states. The 27 EU member states that exist in 2017 are free to tighten the requirements.

3.2 National regulations

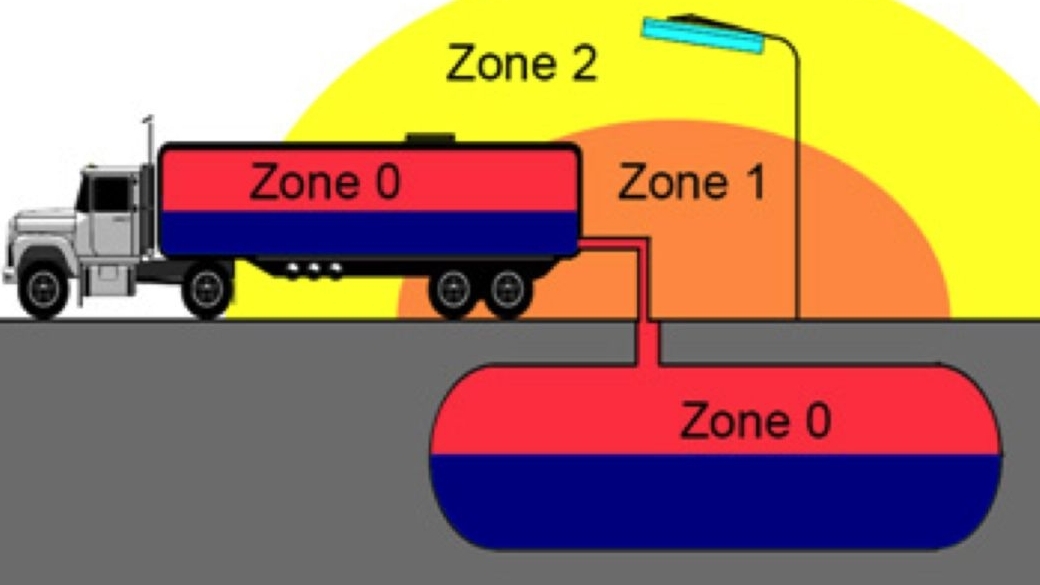

Fig. 11: Ex zone classification using the example of a tank being filled with flammable liquid from a tankerTheoperating regulations for explosion protection are laid down in the Industrial Safety Ordinance, which has been in force since January 2003 and in which the ATEX Directive 1999/92/EC was transposed into German national law. In systems with potentially explosive atmospheres, only devices in accordance with the ATEX product directive 94/9/EC may be used. This is then a system requiring monitoring within the meaning of Section 2 No. 30 of the Product Safety Act (ProdSG) and the Explosion Protection Products Ordinance, which replaced the Explosion Protection Ordinance in 2016.

The operating regulations for explosion protection are laid down in the Industrial Safety Ordinance, which has been in force since 2003 and in which the ATEX Operating Directive 1999/92/EC was also transposed into national German law. In systems with potentially explosive atmospheres, only devices in accordance with the ATEX product directive 94/9/EC may be used. It is then a system requiring monitoring within the meaning of § 2 No. 30 of the Product Safety Act (ProdSG).

The scope and type of operational inspections prior to initial commissioning and recurring inspections as well as the requirements for the "competent persons" for this purpose are described in the Industrial Safety Ordinance of 2015 and the associated Technical Regulations (TRBS).

The 2016 amendment to the Hazardous Substances Ordinance (GefStoffV [21]) deals primarily with the national requirements for risk assessment and protective measures against fire and explosion hazards in Germany. The explosion protection document with the zone classifications was also moved from the Ordinance on Industrial Safety and Health to the annex of the GefStoffV.

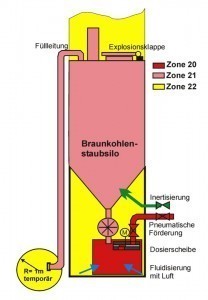

Fig. 12: Ex zone classification using the example of a powder tankEvenif the form of the explosion protection document [22] is not prescribed in detail, it must at least document the following in addition to the general requirements for the risk assessment:

- Determination and evaluation of the explosion hazards

- Development of an explosion protection concept

- Preparation of an explosion protection zone plan (Fig. 11, 12)

- List of areas for which explosion protection measures have been established

- Regulation of cooperation with various companies

- Type and manner of inspections of protective measures.

For explosive liquids, the hazard classifications apply with zones 0, 1 and 2, for explosive dusts accordingly 20, 21 and 22. The zones have the following meaning:

- Zone 0 or 20: permanent or frequent explosion hazard

- Zone 1 or 21: occasional explosion hazard

- Zone 2 or 22: rare or short-term explosion hazard.

Other relevant documents may be helpful in assessing an explosion hazard, such as the hazardous substance register and reaction matrix, list of explosion-protected devices or the relevant alarm and hazard prevention plans.

3.3 Standards and technical regulations

In addition to the statutory regulations, standards associations, employers' liability insurance associations, professional associations and the Federal Ministry of the Interior, among others, have created numerous implementation aids within the framework of sub-statutory regulations. As a result, a wide range of standards, technical regulations and information documents based on professional experience are available. These helpful documents are therefore constantly being adapted to the current state of the art.

3.3.1 Explosion protection standards

The technical and scientific "Verband der Elektrotechnik, Elektronik und Informationstechnik, VDE" in Germany compiles the most frequently required safety standards for electrical engineering relevant to explosion protection. They are selected and updated in close cooperation with the Physikalisch-Technische Bundesanstalt, PTB, and the Explosion Protection Working Group of the German Electrical and Electronic Manufacturers' Association, ZVEI.

These standards are not only important for those bodies that are fundamentally concerned with technical safety requirements as well as testing and certification in explosion protection, but also for all those who manufacture, market or use equipment and components for their intended use in potentially explosive atmospheres [23].

Some examples are listed below:

- DIN EN 1127-1 Explosive atmospheres, explosion protection Part 1, principles and methodology

- EN 13237 Definitions for equipment and protective systems intended for use in potentially explosive atmospheres

- EN 13463-1 Non-electrical equipment for use in potentially explosive atmospheres, principles and requirements

- EN 13463-3 Non-electrical equipment for use in potentially explosive atmospheres, protection by flameproof enclosure "d"

- EN 13463-5 Non-electrical equipment for use in potentially explosive atmospheres, protection by constructional safety "c"

- EN 13463-6 Non-electrical equipment for use in potentially explosive atmospheres, protection by ignition source monitoring "b"

- EN 13463-8 Non-electrical equipment for use in potentially explosive atmospheres, protection by liquid containment "k"

-

EN 14491 Protective systems for pressure relief of dust explosions

-

EN 14797 Explosion venting devices.

-

DIN EN 13980:2003-02 Safety principles for potentially explosive atmospheres and the application of the quality management system, replaced by EN 80079-34

-

EN 80079-34: Potentially explosive atmospheres - Part 34: Application of quality management systems for the manufacture of equipment

-

EN 60079-0: Explosive atmospheres - Part 0: Equipment - General requirements

3.3.2 Technical rules for explosion protection

Fig. 13: Flow diagram as a methodical approach to explosion protection (Image: Rainer Sielker)Technical rules are recommendations and technical proposals, primarily in the field of occupational health and safety, which specify a way to comply with a law, a regulation or a technical procedure. Although they do not themselves have the character of legal regulations, they do describe the current "state of the art", as required by many laws.

If these recommendations are complied with, legislators and trade supervisory authorities generally assume that processes and systems are being operated correctly. In the event of an accident, the employer can prove that he cannot be accused of negligence [24].

Some relevant technical rules on operational safety, TRBS, and the handling of hazardous substances, TRGS, are cited below as examples:

- TRBS 2152 Part 4: Hazardous explosive atmospheres - Measures of constructive explosion protection which limit the effects of an explosion to a harmless level

- TRBS 1111: Risk assessment and safety-related evaluation

- TRBS 1112 Part 1: Explosion hazards during and caused by maintenance work - Assessments and protective measures

- TRBS 1201 Part 1: Inspection of installations in potentially explosive atmospheres and inspection of workplaces in potentially explosive atmospheres

- TRGS 2152/ TRGS 720: Hazardous explosive atmospheres, Part 1-4

- TRGS 721: Hazardous explosive atmospheres - Part 1: Assessment of explosion hazards

- TRGS 722: Hazardous explosive atmospheres - Part 2: Prevention or restriction of formation

- Explosion protection rules (EX-RL) DGUV Rule 113-001

In addition, protective measures must be taken against physical and chemical effects, in particular against fire and explosion hazards. Hazards from explosive substances, preparations and products also arise from explosive reaction systems, e.g. decomposition of acetylene, physical explosions, such as those caused by the introduction of high-melting-point molten metals into water, and incompatible systems, substances that must not come into contact with each other, such as copper and acetylene [25].

3.4 Explosion protection document

Chapter 3.2 "National regulations" already contains some basic considerations on the explosion protection document. The 2015 amendment to the Ordinance on Industrial Safety and Health is intended to simplify matters, create legal certainty and at the same time improve employee protection. To this end, duplicate regulations have been eliminated and specific inspection regulations have been formulated. The most important changes include [26]:

- the inclusion of installations requiring monitoring in the risk assessment

- specific inspection regulations in Annexes 2 and 3

- exclusive regulation of the material requirements for fire and explosion protection in the Hazardous Substances Ordinance.

Explosion protection documents must be prepared and kept up to date by the employers concerned, regardless of the number of employees.

To create the explosion protection document, the explosion hazard is determined and subjected to an expert assessment. The assessment team determines the measures and precautions required to achieve the explosion protection objectives. The potentially explosive areas are divided into appropriate zones, and the division is recorded and documented in an Ex zone plan. The risk assessment of the areas is an essential part of the explosion protection document. The explosion protection document must be drawn up before work commences and kept up to date [27].

A systematic aid for the necessity of explosion protection is the flow chart [28] according to Rainer Sielker (Fig. 13).

Fig. 10: Marking of devices for operation in potentially explosive atmospheres in accordance with the ATEX Product Directive 2014/34/EUTheEuropean Commission in Brussels has drawn up "ATEX Directives" for both plant manufacturers [19] and producers [20], which guarantee basic safety and health requirements in explosion protection in a harmonized and updated manner. ATEX is derived from the French abbreviation for "ATmosphères Explosibles" (explosive atmospheres).

Fig. 10: Marking of devices for operation in potentially explosive atmospheres in accordance with the ATEX Product Directive 2014/34/EUTheEuropean Commission in Brussels has drawn up "ATEX Directives" for both plant manufacturers [19] and producers [20], which guarantee basic safety and health requirements in explosion protection in a harmonized and updated manner. ATEX is derived from the French abbreviation for "ATmosphères Explosibles" (explosive atmospheres). Fig. 11: Ex zone classification using the example of a tank being filled with flammable liquid from a tankerTheoperating regulations for explosion protection are laid down in the Industrial Safety Ordinance, which has been in force since January 2003 and in which the ATEX Directive 1999/92/EC was transposed into German national law. In systems with potentially explosive atmospheres, only devices in accordance with the ATEX product directive 94/9/EC may be used. This is then a system requiring monitoring within the meaning of Section 2 No. 30 of the Product Safety Act (ProdSG) and the Explosion Protection Products Ordinance, which replaced the Explosion Protection Ordinance in 2016.

Fig. 11: Ex zone classification using the example of a tank being filled with flammable liquid from a tankerTheoperating regulations for explosion protection are laid down in the Industrial Safety Ordinance, which has been in force since January 2003 and in which the ATEX Directive 1999/92/EC was transposed into German national law. In systems with potentially explosive atmospheres, only devices in accordance with the ATEX product directive 94/9/EC may be used. This is then a system requiring monitoring within the meaning of Section 2 No. 30 of the Product Safety Act (ProdSG) and the Explosion Protection Products Ordinance, which replaced the Explosion Protection Ordinance in 2016. Fig. 12: Ex zone classification using the example of a powder tankEvenif the form of the explosion protection document [22] is not prescribed in detail, it must at least document the following in addition to the general requirements for the risk assessment:

Fig. 12: Ex zone classification using the example of a powder tankEvenif the form of the explosion protection document [22] is not prescribed in detail, it must at least document the following in addition to the general requirements for the risk assessment: Fig. 13: Flow diagram as a methodical approach to explosion protection (Image: Rainer Sielker)Technical rules are recommendations and technical proposals, primarily in the field of occupational health and safety, which specify a way to comply with a law, a regulation or a technical procedure. Although they do not themselves have the character of legal regulations, they do describe the current "state of the art", as required by many laws.

Fig. 13: Flow diagram as a methodical approach to explosion protection (Image: Rainer Sielker)Technical rules are recommendations and technical proposals, primarily in the field of occupational health and safety, which specify a way to comply with a law, a regulation or a technical procedure. Although they do not themselves have the character of legal regulations, they do describe the current "state of the art", as required by many laws.