SCIP stands for "substances of concern in products" and is a new database that has been set up by the European Chemicals Agency (ECHA) and will be accessible in all member states. It is planned to feed it with a wealth of information on "substances of concern" in products. This information will be available to waste management companies, who will then know which waste contains substances of concern. The ultimate aim of the database is to remove such hazardous substances from the economic cycle once and for all and thus come a step closer to the EU Commission's "Tox-Free Environment" target. It will start in January 2021.

All manufacturing companies are well advised to get to grips with this as soon as possible, as data procurement will be the real challenge. For example, when a car or electronic device is placed on the market in the EU, there are highly complex supply chains in production. It is not unusual to find hundreds of suppliers in Asian countries or on other continents. However, the database can only be "fed" if all the necessary information from all suppliers is available. However, manufacturers of less complex products such as packaging, toys or textiles are also affected.

SCIP is intended to collect information on substances of concern or substances of very high concern in articles or complex products (such as lead stabilizers or plasticizers in plastic components, brominated flame retardants in electronic devices, polyaromatic hydrocarbons in tire granules, etc.). The database has its legal basis in EU law, in the Waste Framework Directive (AbfRRil). SCIP is based on Article 9 (1) (i) in conjunction with (2) of the recently amended Waste Framework Directive. This is another attempt to more closely integrate chemicals and waste legislation. Member States are required to set targets for waste prevention measures. The wording in the Waste Framework Directive as the legal basis for SCIP is as follows:

"... (i) without prejudice to harmonized legislation applicable at Union level to the materials and products concerned, to promote the reduction of the content of hazardous substances in materials and products and to ensure that the supplier of an article within the meaning of Article 3(33) of Regulation (EC) No 1907/2006 of the European Parliament and of the Council1) provides the European Chemicals Agency with the information referred to in Article 33(12) of that Regulation from 5 January 2021 ..."

The current AbfRRil is therefore the basis for waste management in the EU and contains extensive requirements for the proper disposal of waste. It must be transposed into the national law of the EU member states by July 2020. In Germany, the draft bill for the Closed Substance Cycle Waste Management Act (KrWG) addresses this with the new Section 62a. This gives the ECHA until January 5, 2021 to set up the database.

For suppliers of an article that may contain substances on the candidate list, Art. 9 para. 1 letter i) of the AbfRRil subsequently provides for corresponding notification obligations to the ECHA. The so-called candidate list (Annex XIV of the REACh Regulation) currently contains around 200 substances that must fulfill the criteria of Art. 57 of the REACh Regulation:

-

Substances to be classified as carcinogenic or mutagenic or toxic for reproduction of category 1A or 1B according to Regulation (EC) No. 1272/2008 (CMR substances)

-

Substances that are persistent and bioaccumulative and toxic according to the criteria of Annex XIII of the REACh Regulation (PBT substances)

-

Substances that are very persistent and very bioaccumulative (vPvB substances) according to the criteria of Annex XIII of the REACh Regulation

-

Substances which, according to scientific findings, are likely to have serious effects on human health or the environment, but which cannot be assigned to the above-mentioned groups - e.g. endocrine disruptors.

The EU Commission's request to provide recycling and disposal companies with more information on substances of concern is correct. In most cases, waste management companies today do not know which substances of concern are contained in the waste to be disposed of (e.g. electronic waste, batteries or packaging) when it arrives for recycling and, above all, whether these substances are present at all. If certain parts are to be sent for recycling, chemical analyses are then necessary. The EU Commission now wants to address the information deficit on the waste management side with SCIP. The aim is to create more transparency about the composition or presence of hazardous substances in complex products. This transparency is to be created by the manufacturers, who can still use harmful substances today - in some cases with legally regulated exceptions (e.g. lead in various compounds).

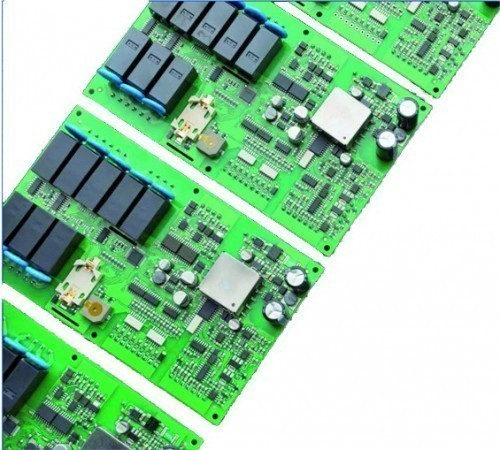

Companies that supply articles containing substances of very high concern (svhc) in a concentration of more than 0.1% (w/w) on the EU market must submit information on these articles to ECHA from January 5, 2021. An "article" is an object that contains a specific shape, surface or design during manufacture (e.g. cable or screw on a printed circuit board). This definition can be found in Art. 3 of the REACh Regulation; "complex objects" will soon also be affected by the reporting obligation. These are products consisting of more than one article (e.g. printed circuit board).

The SCIP database is only applicable if a large number of affected manufacturers participate. SCIP stipulates, for example, that information beyond the legal requirements must be entered. This means that not only information on substances of very high concern, but also "substances of concern" must be entered, i.e. substances that are restricted in products by regulations other than REACh (e.g. POP Regulation3)).

The information (consisting of article names, concentration ranges, localization of the svhc substance, information on the safe use of the substance) in the database will then be made available to waste disposal companies and consumers. Whether this ambitious project will be crowned with success, however, is more than questionable. Car manufacturers4) and manufacturers of electrical appliances5) (see examples below) have already announced that it will only be possible to provide billions of individual items of information per manufacturer at considerable expense. The database will result in high costs and very time-consuming information procurement. But recyclers6) have also already communicated that SCIP will not be helpful.

What examples illustrate the problems of SCIP?

Fig.1: IMDS article description (from presentation by Unger T., 2020)Example data supplier automotive industry: The automotive industry has relied on IMDS - International Material Data System7) as a database for materials and components since the first regulations on end-of-life vehicle recycling came into force. According to the European industry (T. Unger, 2020), it cost around 10 billion euros to establish the database. Access is available to anyone who asks the operator. The material and chemical compositions of components, semi-finished products and materials are declared in the IMDS material data. The main benefit of IMDS material data is the safeguarding and verification of legal substance regulations for complete vehicles and their spare parts. Furthermore, IMDS material data is used as a data source for calculating the recycling rate according to ISO 22628 in the system approval of the EU type approval. IMDS is currently accessed by around 130,000 active users and around 14,000 materials are reported. Apart from aircraft, passenger cars are certainly the most complex products affected by SCIP. The establishment of SCIP now means that for thousands of individual affected articles per vehicle, all the necessary information on svhc must be obtained from suppliers in the EU and outside the EU. Figure 1 uses an electronic component from a vehicle to illustrate that even the designation of an "article" or product is not easy because there are often no universally valid proper names. The European automotive industry expects to spend several billion euros on this complex data collection for hazardous substances because the current IMDS structure cannot be used.

Fig. 2: Printed circuit board with many hundreds of individual articlesExampledata supplier electrical and electronics industry: Electronic assemblies - e.g. printed circuit boards fitted with electronic components - typically have several hundred assembly positions with a large number of electronic components; these are "articles" according to REACh. The majority of the electronic components used are typically in a weight range of 2 mg to 5 g(Fig. 2). The amount of information to be provided to ECHA is further increased by the "multiple sourcing" common in the electronics industry (several suppliers per assembly item). In the case of assembled printed circuit boards, it is not possible to identify the electronic component to which the information entered in SCIP belongs, because such a component usually has no identification features that would allow it to be distinguished from other components. A member of the ZVEI recently calculated the effort involved. It identified 2651 end products containing brass components with low lead content (lead is a svhc substance on the REACh candidate list). This results in 426,370 combinations of parts uses of these components in end products, which would have to be entered in the database. For all parts and substances concerned, this company would have to employ a total of 23 people for one year in order to map each article variant once in the SCIP database.

Example data user recycling industry: The nature of today's recycling technologies (e.g. dismantling plant for end-of-life vehicles and shredder plant) will hardly allow individual substance information on substances of concern to be determined for each component of a vehicle in day-to-day business. Hundreds of different vehicle models of various compositions are usually disposed of in one plant, and what counts here is essentially a high throughput in tonnage in order to ensure economic recycling in view of the raw material price situation. If substances of concern have to be removed from individual "mini-products" (such as screws, soldering contacts) in the future, economic recycling is practically no longer possible, as testing for the presence of substances of concern alone will take far too long. This applies not only to vehicles, but also to many other complex products. The question also needs to be answered: is this even necessary to achieve the EU's "Tox-Free Environment" target? The svhc substance lead as an additive in steel alloys, for example, changes into the gaseous aggregate state during the recycling process and does not remain in the melt. This automatically separates individual alloy components. Electronic waste is treated separately by specialized recyclers in accordance with the WEEE Directive, and manufacturers already provide the information required by Article 15 of the WEEE Directive (e.g. via the I4R platform). In the recycling process, only very specific components (such as batteries) are removed manually before the remaining parts go through the sorting and treatment processes. In the case of complex electronic devices, the substance of very high concern is usually contained in very small quantities in small sub-particles of the product (see example of assembled printed circuit board in Fig. 2). Detailed information on these tiny sub-particles (article category, material category) is not helpful for recyclers, as knowledge of the presence of svhc substances would usually not change the final, often metallurgical, treatment process. Some svhc substances (such as organic hydrocarbon compounds) do not survive the recycling process at all; they are destroyed by the high process temperatures.

What happens next?

In February 2020, ECHA published a database prototype. This can be found at the following link:

https://echa.europa.eu/de/scip-prototype. The full version will then be set up in the course of the year. Manufacturers or suppliers of products containing svhc are obliged to submit information to the SCIP database from January 2021. This requires the IUCLID 6 software, which already had to be used for the registration of substances and can be obtained free of charge from the ECHA website (www.echa.europa.eu). ECHA has already announced that it will hold webinars on the use of the SCIP database for affected companies. The EU member states must now establish specific aspects of the legal enforcement of the SCIP database in national law by summer 2021.

What are the main points of criticism?

The application of the new database will pose enormous difficulties. First of all, it is of paramount importance to make all companies concerned aware of their obligations. From today's perspective, it is more than questionable whether this will succeed in the foreseeable future in view of the current economic crisis and the many years of experience with REACh. In the coming months, trade associations, chambers, ECHA and training institutes should offer numerous events to draw attention to SCIP and present the use of the prototype. At this point, it would be helpful to first familiarize oneself with the enforcement experience with REACh and the implementation of the existing information obligation for articles.

In a market surveillance program, for example, the obligation to apply Article 33, which has been in place since 2007 (!!) and already includes the obligation to provide information (notification) on substances of concern in the supply chain, was reviewed. In 15 countries, it was examined whether article manufacturers comply with their obligation to provide information on substances of very high concern (svhc). The result is alarming: there is a high non-compliance rate of over 80%. This means that more than three quarters of the companies investigated do not receive the necessary information on svhc from suppliers or do not pass it on to customers8). It is therefore doubtful at this point that data for SCIP is reported to a sufficient extent. The handling will also be considerably more complex and opaque than the current obligation to provide information in accordance with Art. 33 within the supply chain.

The use of the SCIP database by recyclers is also more than questionable. Even if the intention to bring more transparency to material flows is correct, SCIP will not be able to contribute to "shedding more light on the pollutants in waste" from today's perspective. Recycling companies work on a ton scale, the input into the processing plants is fed by many different models (see example above: thousands of models of vehicles and electrical appliances). Even with a somewhat simpler material flow such as packaging, the recyclers don't have it much easier. In addition, article designations are not communicated to the recycler; a sorting plant for packaging, for example, is not designed to sort by article number but by color, type of plastic, etc. The recycler is usually not informed of the article number. The recycler will generally not have time to take care of further information if they have to generate revenue in a short space of time.

A broad discussion with all market participants in the EU would therefore have been more than helpful prior to the adoption of SCIP, so that a well-intentioned proposal can be made a success. The overlap between waste and chemicals legislation is extremely complex, which is why a good sense of proportion is required if the well-intentioned goal of a "tox-free environment" in particular is to succeed in the long term. However, an impact assessment is urgently needed for SCIP, and the involvement of data owners and recyclers would be necessary in such a project in order to assess the effort, costs and benefits.

Is there an alternative to SCIP?

There is no alternative to more recycling and greater use of recycled raw materials in order to meet the EU Commission's climate protection and resource conservation targets. In order to solve the "pollutant problem" in waste, more trust in the economy is necessary. Today, there are a large number of restrictions on harmful substances that are already regulated in chemicals, materials and waste legislation. Here are just a few examples, all of which must be applied when placing new products on the market: Toys Directive, End-of-Life Vehicles Directive, Electronic Waste Directive and ROHS (EU Directive 2011/65/EU serves to restrict the use of certain hazardous substances in electrical and electronic equipment), Packaging Directive, substance restrictions in Annex XVII of the REACh Regulation, POP Regulation. The application of all the regulations already in place today will gradually - in conjunction with REACh - lead to fewer and fewer substances of concern reaching the waste management sector. Even today, there are hardly any cases in which recycled waste has led to a pollutant problem in production. Today, the much greater challenge is to bring more waste into high-quality recycling in order to save more resources, especially non-renewable resources. In the worst-case scenario, SCIP will lead to even more pollutant extraction being required in recycling, which will then lead to even more waste streams being disposed of. As a result, large quantities of valuable resources will be lost, which would also be necessary for successful climate protection.

The EU must therefore move away from a completely pollutant-free recycling economy and continue to pursue a "tox-free environment". Today, we already find ubiquitous pollutants in all environmental media, which represent the so-called background pollution. This pollution is the result of decades of water pollution, emissions from industry, traffic, agriculture, etc. However, we have already achieved a great deal through strict environmental and product legislation. Especially today, in times of a foreseeable massive economic and raw materials crisis and the threat of a climate catastrophe, it is not appropriate to invest billions of euros in a new database that is unlikely to work. Instead, we need to consider with a sense of proportion how climate gas reduction and resource conservation can be regulated within the EU. Additional burdens for the economy, which cause high costs and bring little benefit and are also not enforceable, are not needed at present.

The chances of changing or even dispensing with a SCIP database are currently extremely low, which is why manufacturing companies are well advised to look into this

(https://echa.europa.eu/de/scip-database) and, if necessary, seek external scientific advice.

Sources

1) REACh Regulation

2) Art. 33 para. 1 REACh Regulation: Art. 33 para. 1 of Regulation 1907/2006/EC (hereinafter also referred to as the "REACh Regulation") obliges suppliers of articles containing at least one SVHC substance in a concentration of more than 0.1% by weight to provide the recipient of the articles with sufficient information available to them for the safe use of the articles, but at least the name of the substance concerned

3) POP Regulation: Regulation (EU) 2019/1021 of June 20, 2019 on persistent organic pollutants

4) Unger, T. (Hyndai), presentation "The Substances of Concern in Products Database (SCIP)", Annual Conference on Product Safety in the Chemical Industry, January 20-21, 2020, Bonn, Germany

5) Statement on the SCIP database and its national implementation, ZVEI, bitkom and VDMA, January 20, 2020

6) EURIC - Statement at the Joint Workshop of the Chemicals Articles Waste Cross Industry Platform, June 17, 2019, Brussels; Risk to generate an enormous amount of unmanageable information. We work in tons, not in units

7) The IMDS (International Material Data System) is the material data system of the automotive industry. It is a joint development of Audi, BMW, Daimler, DXC, Ford, Opel, Porsche, VW and Volvo. Other manufacturers have since joined the network, making IMDS a global standard that is used by almost all globally active OEMs. Talks are also being held with other manufacturers about participating in IMDS. All materials used in the manufacture of cars are collected, maintained, analyzed and archived in IMDS. By using the IMDS, it is possible to fulfill the obligations placed on car manufacturers and their suppliers by national and international standards, laws and regulations

Fig.1: IMDS article description (from presentation by Unger T., 2020)Example data supplier automotive industry: The automotive industry has relied on IMDS - International Material Data System7) as a database for materials and components since the first regulations on end-of-life vehicle recycling came into force. According to the European industry (T. Unger, 2020), it cost around 10 billion euros to establish the database. Access is available to anyone who asks the operator. The material and chemical compositions of components, semi-finished products and materials are declared in the IMDS material data. The main benefit of IMDS material data is the safeguarding and verification of legal substance regulations for complete vehicles and their spare parts. Furthermore, IMDS material data is used as a data source for calculating the recycling rate according to ISO 22628 in the system approval of the EU type approval. IMDS is currently accessed by around 130,000 active users and around 14,000 materials are reported. Apart from aircraft, passenger cars are certainly the most complex products affected by SCIP. The establishment of SCIP now means that for thousands of individual affected articles per vehicle, all the necessary information on svhc must be obtained from suppliers in the EU and outside the EU. Figure 1 uses an electronic component from a vehicle to illustrate that even the designation of an "article" or product is not easy because there are often no universally valid proper names. The European automotive industry expects to spend several billion euros on this complex data collection for hazardous substances because the current IMDS structure cannot be used.

Fig.1: IMDS article description (from presentation by Unger T., 2020)Example data supplier automotive industry: The automotive industry has relied on IMDS - International Material Data System7) as a database for materials and components since the first regulations on end-of-life vehicle recycling came into force. According to the European industry (T. Unger, 2020), it cost around 10 billion euros to establish the database. Access is available to anyone who asks the operator. The material and chemical compositions of components, semi-finished products and materials are declared in the IMDS material data. The main benefit of IMDS material data is the safeguarding and verification of legal substance regulations for complete vehicles and their spare parts. Furthermore, IMDS material data is used as a data source for calculating the recycling rate according to ISO 22628 in the system approval of the EU type approval. IMDS is currently accessed by around 130,000 active users and around 14,000 materials are reported. Apart from aircraft, passenger cars are certainly the most complex products affected by SCIP. The establishment of SCIP now means that for thousands of individual affected articles per vehicle, all the necessary information on svhc must be obtained from suppliers in the EU and outside the EU. Figure 1 uses an electronic component from a vehicle to illustrate that even the designation of an "article" or product is not easy because there are often no universally valid proper names. The European automotive industry expects to spend several billion euros on this complex data collection for hazardous substances because the current IMDS structure cannot be used. Fig. 2: Printed circuit board with many hundreds of individual articlesExampledata supplier electrical and electronics industry: Electronic assemblies - e.g. printed circuit boards fitted with electronic components - typically have several hundred assembly positions with a large number of electronic components; these are "articles" according to REACh. The majority of the electronic components used are typically in a weight range of 2 mg to 5 g(Fig. 2). The amount of information to be provided to ECHA is further increased by the "multiple sourcing" common in the electronics industry (several suppliers per assembly item). In the case of assembled printed circuit boards, it is not possible to identify the electronic component to which the information entered in SCIP belongs, because such a component usually has no identification features that would allow it to be distinguished from other components. A member of the ZVEI recently calculated the effort involved. It identified 2651 end products containing brass components with low lead content (lead is a svhc substance on the REACh candidate list). This results in 426,370 combinations of parts uses of these components in end products, which would have to be entered in the database. For all parts and substances concerned, this company would have to employ a total of 23 people for one year in order to map each article variant once in the SCIP database.

Fig. 2: Printed circuit board with many hundreds of individual articlesExampledata supplier electrical and electronics industry: Electronic assemblies - e.g. printed circuit boards fitted with electronic components - typically have several hundred assembly positions with a large number of electronic components; these are "articles" according to REACh. The majority of the electronic components used are typically in a weight range of 2 mg to 5 g(Fig. 2). The amount of information to be provided to ECHA is further increased by the "multiple sourcing" common in the electronics industry (several suppliers per assembly item). In the case of assembled printed circuit boards, it is not possible to identify the electronic component to which the information entered in SCIP belongs, because such a component usually has no identification features that would allow it to be distinguished from other components. A member of the ZVEI recently calculated the effort involved. It identified 2651 end products containing brass components with low lead content (lead is a svhc substance on the REACh candidate list). This results in 426,370 combinations of parts uses of these components in end products, which would have to be entered in the database. For all parts and substances concerned, this company would have to employ a total of 23 people for one year in order to map each article variant once in the SCIP database.