Whether smartphone, notebook or even electric car: many mobile devices are powered by lithium batteries. However, only the transportation of these batteries is regulated by law. In addition, the handling and storage instructions recommended by the manufacturer apply.

In lithium-ion batteries, flammable components and fire promoters are installed together in a "tank" - the battery cell. The positive and negative terminals are only separated from each other by wafer-thin separators, which is the source of the fire hazard. The thinner the separators, the more space-saving the housing can be and the higher the capacity of the cell. Conductivity is ensured by an electrolyte that must be completely free of water due to the reactive lithium components, but therefore consists of highly flammable chemicals. Research into the causes of damage to many commercially available energy storage systems has shown that the wafer-thin separators are very fragile and that puncturing them can inevitably lead to a short circuit with severe heating and even fire. Such short circuits can also be caused by mechanical damage due to falling or vibration etc.. It can take hours or days for a thermal runaway to occur, so a fire can still occur long after a hard impact (Fig. 1). If the battery then burns with an air supply, the rule of thumb is that the thermal energy released by the battery materials is around 10 times the electrical capacity of the battery. To prevent danger, a "calorific value" can be calculated for each lithium-ion battery, which can be converted into a certain amount of gasoline to illustrate the harmless appearance of these energy storage devices.

Battery care when charging

There are a few simple rules to follow to ensure trouble-free operation and a high level of safety:) Damaged batteries should not be charged; this also applies to batteries that have "only" crashed and appear undamaged on the outside. Never charge batteries below approx. 10 °C and above approx. 40 °C, as this can lead to internal damage. The same applies to cold and hot batteries during operation; here too, the specified temperature window should be adhered to as far as possible. Only the intended charger may be used for charging. Otherwise, the battery or individual cells can quickly become overcharged, as the balancing function of the battery management system (BMS), which brings all battery cells to the same state of charge, will not work.

Fault-tolerant charging

At first glance, a battery fire seems to be the exception rather than the rule with branded products, but as more and more batteries are being used, the number of fires caused by lithium batteries is also increasing. As faults can be invisible, fires cannot be 100% avoided, but there are good solutions to prevent consequential damage: The simplest method is charging in a fireproof environment with safety distances, which is almost impossible to implement in operational practice without further ado. Flame-retardant bags are available for hobbyists, e.g. for cell phone batteries or model making, but these quickly reach their limits and are not reliable enough for professional use. Special charging cabinets, on the other hand, are the first choice for professional charging activities. There are different variants depending on requirements. The fireproof charging cabinets with built-in sockets are ideal for companies that need to keep charged batteries on site at the workplace during pedelec production, for example (Fig. 2).

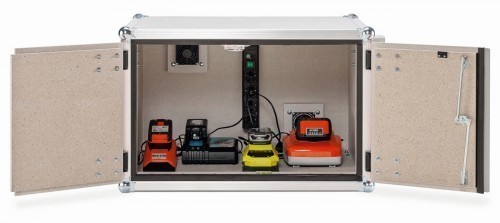

Figure 3: Compact battery charging cabinets for tool and other small batteries with alarm in case of fire

Figure 3: Compact battery charging cabinets for tool and other small batteries with alarm in case of fire

Smaller charging cabinets with a graduated safety concept are ideal for smaller battery quantities, e.g. for tools or pedelec rental. The range extends from simple models with smoke detectors and power cut-off in the event of fire due to heat development to versions with remote alarming via mobile radio (Fig. 3). This ensures constant monitoring even without employees on site, a significant increase in safety that is often reflected in a reduction in insurance premiums.

About Cemo

As a manufacturer of GRP products and a full-service provider of solutions in the areas of storage, distribution and safe handling, Cemo offers a wide range of products for many industries. Other services, such as consulting, complement the practical portfolio.

The pioneer in the field of modern transport and storage container technology and Germany's market leader for legally compliant complete systems for self-consumption filling stations and safe lithium battery charging cabinets also offers professional solutions for the storage of water-polluting substances. Another mainstay of the company is heating oil tanks with 72-hour delivery service to the customer, winter service equipment such as grit containers and spreaders as well as traditional transport and storage containers for construction and agriculture.