Even if manufacturers say otherwise: Maintaining existing systems or equipment makes more ecological sense than purchasing new ones. This is also an option for coated components.

A basic idea of circular and sustainable management is to keep components or products in a functional condition for as long as possible. This can be achieved by remaking. This includes repairing defects, refurbishing, i.e. overhauling and reconditioning or remanufacturing.

Example of hot-dip galvanized components: If the zinc coating produced by hot-dip galvanizing no longer provides sufficient corrosion protection due to an extremely long service life or other influences, hot-dip galvanized steel components can be re-galvanized. The steel components are dezincified in the galvanizing plant and then re-galvanized. As the dezincification of steel parts is part of daily practice in galvanizing plants, repair by dezincification and re-galvanizing is possible in every galvanizing plant. Re-galvanizing gives the steel component another 50 years or more of corrosion protection without any loss of quality. This saves a great deal of resources, energy andCO2 and thus makes a further valuable contribution to sustainability. It is also possible to galvanize rusty, colour-coated components in many cases. This allows such components to benefit from permanent corrosion protection, albeit only at the second attempt.

Re-galvanizing hot-dip galvanized steel

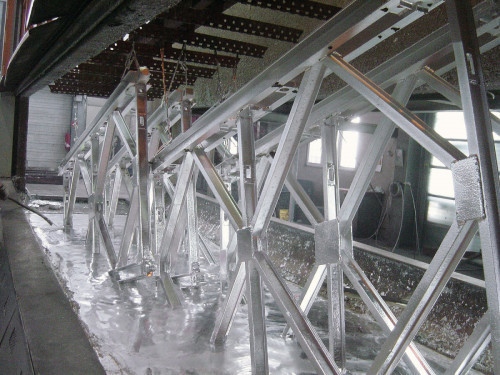

Bailey bridge elements in the zinc bath (Photo: Institut Feuerverzinken)A life cycle assessment (LCA) study by the Dutch research institute CE Delft shows the sustainability of re-galvanizing. The use of newly galvanized freeway crash barriers (including transport and dismantling and reassembly) has a five times lowerCO2 footprint and five times lower primary energy consumption than replacement with new crash barriers. This saves 112 kg ofCO2 and 1405 MJ of energy per meter of newly galvanized crash barrier. However, the newly galvanized crash barriers not only showed better results in terms of carbon dioxide and energy consumption, but also in all impact categories examined as part of the sustainability study. In terms of the Federal Republic of Germany, millions of tons ofCO2 could be saved on 13,000 kilometers of freeway and 38,000 kilometers of rural road by re-galvanizing crash barriers. And not only here, but also in many other areas of application, gigantic emissions and energy savings are possible by re-galvanizing.

Bailey bridge elements in the zinc bath (Photo: Institut Feuerverzinken)A life cycle assessment (LCA) study by the Dutch research institute CE Delft shows the sustainability of re-galvanizing. The use of newly galvanized freeway crash barriers (including transport and dismantling and reassembly) has a five times lowerCO2 footprint and five times lower primary energy consumption than replacement with new crash barriers. This saves 112 kg ofCO2 and 1405 MJ of energy per meter of newly galvanized crash barrier. However, the newly galvanized crash barriers not only showed better results in terms of carbon dioxide and energy consumption, but also in all impact categories examined as part of the sustainability study. In terms of the Federal Republic of Germany, millions of tons ofCO2 could be saved on 13,000 kilometers of freeway and 38,000 kilometers of rural road by re-galvanizing crash barriers. And not only here, but also in many other areas of application, gigantic emissions and energy savings are possible by re-galvanizing.

Galvanizing coated steel

Even for colour-coated steel, there may be an opportunity for a long-term and maintenance-free corrosion protection solution through hot-dip galvanizing. Not every, but many old paint-coated structures can be prepared for hot-dip galvanizing by means of minor modifications in accordance with the rules of hot-dip galvanizing-compatible design and thus escape the environmentally harmful maintenance cycles associated with paint coatings on ungalvanized steel. To achieve this, paint stripping of the structure is required. This can be done by thermal paint stripping and/or blasting. One example of this is old coated Bailey bridges, which can be hot-dip galvanized at a manageable cost and are thus permanently protected against corrosion.

Conclusion:

Hot-dip galvanized steel is not only durable, reusable and recyclable without any loss of quality. It can also be restored to a new condition again and again by re-galvanizing and thus made fit for one, two, three, many new lives. This saves energy andCO2. Galvanizing is also an option for repairing many coated steel structures.