The bonding of CFRP components can be significantly improved with the help of appropriate pre-treatment processes; atmospheric plasmas and flames in particular represent alternatives to the use of environmentally hazardous chemicals. However, the choice of process is important.

Introduction

With regard to construction materials, lightweight construction materials play an important role. On the one hand, against the background of sustainable management (energy consumption during production, reduction of the mass of moving parts, reduction of transportation costs and exhaust gases), current work is focusing on reducing the weight of systems and machines and their components. Depending on the materials used, potential weight savings of between 10 % (lightweight steel construction) and up to 40 % (aluminum) have been identified compared to conventional steel construction, while CFRP materials offer further potential of up to 60 % compared to aluminum [1]. On the other hand, alternative transportation concepts, e.g. based on fuel cell technology, require new developments in the field of material development, with hydrogen storage technology being one example. Fiber-reinforced plastics are also of great interest here. The importance of fiber-reinforced plastics will certainly increase in the coming years in view of pressing issues such as climate change and energy policy. The latest market report from Composite United e.V. predicts growth of over 30% in the medium term (from 2022), with the figures based on production increases already announced by the major carbon fiber manufacturers [2].

There is currently no way around bonding technologies in the construction and especially in the joining of fiber-reinforced plastics. Pre-treatments such as the use of suitable chemicals, mechanical roughening or the use of peel ply are required to achieve stable bonds. The latter two processes in particular can lead to damage to the fiber-matrix structure, and the use of chemicals, most of which are harmful to the environment, is also problematic. In this respect, alternative, dry, gas-phase-based pre-treatment methods such as the use of atmospheric plasmas or the use of various flame treatment techniques are sensible alternatives. However, an overview of the efficiency of different pretreatment methods in the field of CFRP bonding has not been available to date.

This article takes a closer look at the influence of various atmospheric plasmas and flames on the surface conditions of CFRP and on the given potential for increasing the bond strength of CFRP bonds.

Materials and methods

Carbon fiber/epoxy test specimens DT120, cut, laid in 0°/90° fiber direction, with the dimensions 100 x 25 x 1.5 mm3 were used for the investigations (Rocholl GmbH). Before use, all samples were first pre-cleaned with kimwipes and isopropanol to remove any residues of release agents, release films or peel plies from the CFRP production, and then sufficiently ventilated. The pre-treatments carried out before bonding were carried out using different physical methods, which are listed in Table 1. For the methods that allow variation of the treatment parameters, the treatment parameters used in this study were determined on the basis of a short preliminary screening for wettability with water. In addition to pure pre-treatments, which only lead to surface activation, layer-forming processes using organosilicon precursors were also investigated, as it is known that thin silicate layers with their high number of integrated OH groups are used as adhesion-promoting coatings. It is also known that the use of primers has a further positive effect on the adhesion properties. A primer SuraLink21 (Sura Instruments GmbH) was used for this purpose.

|

Atmospheric pressure plasma-based pre-treatment methods |

|

|

T-Spot (TIGRES GmbH) |

P = 300 W, air, v = 150 mm/s, BA = 10 mm, RA = 3 mm, 1 DL |

|

CAT (TIGRES GmbH) |

P = 600 W, air, v = 200 mm/s, BA = 5 mm, RA = 6 mm, 1 DL |

|

PFW 10 (Plasmatreat GmbH) |

P = approx. 1000 W, air, v = 300 mm/s, BA = 13 mm, RA = 3 mm, 1 DL |

|

Piezobrush PZ3 (relyon plasma GmbH) |

P = 100%, air, v = 20 mm/s, BA = 1 mm, RA = 3 mm, 1 DL |

|

MSDBD (Roplass s.r.o.) |

P = 30 W, air, BA = approx. 0.3 mm, treatment time = approx. 10 s |

|

T-Spot SiOx |

P = 300 W, air, 2.0 ml/min HMDSO, v = 100 mm/s, BA = 10 mm, RA = 3 mm, 2 DL, plus 1 DL plasma postactivation |

|

T-Spot SiOx + primer |

as "T-Spot SiOx" plus spraying of a primer SuraLink21 |

|

T-Spot SiOx primer composite layer 1 |

P = 230 W, air, 3.0 ml/min HMDSO, 0.10 ml/min SuraLink21, v = 100 mm/s, BA = 10 mm, RA = 3 mm, 3 DL |

|

T-spot SiOx primer composite layer 2 |

P = 230 W, air, 3.0 ml/min HMDSO, 0.35 ml/min SuraLink21, v = 100 mm/s, BA = 10 mm, RA = 3 mm, 3 DL |

|

Flame-based pretreatment methods |

|

|

Flame F1 |

Propane/air ratio 1/25, v = 250 mm/s, BA = 25 mm, 1 DL, |

|

Flame F1 + primer |

as "Flame F1" plus spraying of a primer SuraLink21 |

|

Flame F3 |

Propane/air ratio 1/25, v = 250 mm/s, BA = 25 mm, 4 DL, |

|

Flame F3 + primer |

as "Flame F3" plus spraying of a primer SuraLink21 |

|

Pyrosil® Pyr1 |

Propane/air ratio 1/20, STS 0.4%, v = 250 mm/s, BA = 25 mm, 4 DL |

|

Pyrosil® Pyr1 + primer |

as Pyr1 plus spraying of a primer SuraLink21 |

|

Pyrosil® Pyr2 |

Propane/air ratio 1/20, STS 0.5%, v = 250 mm/s, BA = 25 mm, 6 DL |

|

Pyrosil® Pyr2 + primer |

as Pyr2 plus spraying of a primer SuraLink21 |

|

Pyrosil® Pyr3 |

Propane/air ratio 1/20, STS 0.4%, v = 250 mm/s, BA = 25 mm, 2 DL |

|

Pyrosil® Pyr3 + primer |

as Pyr3 plus spraying on a primer SuraLink21 |

The CFRP test specimens were bonded in accordance with DIN EN 1465 as tensile shear bonds with an overlap bond with a bonding area of 12.5 x 25 mm2, using a Scotch-Weld DP 460 two-component epoxy resin-based construction adhesive (3M Deutschland GmbH), whereby the bonds were cured for 2 h at 95 °C. Before the actual tensile shear test, the bond was subjected to additional stress by immersing it in water at 80 °C for 72 hours. For each set of parameters, ten bonds were produced for corresponding tear-off tests, with three samples reserved for analytical purposes. The ten tear-offs were carried out using an inspect table 50kN tensile testing machine (Hegewald & Peschke, Meß- und Prüftechnik GmbH). Contact angle measurements and the determination of the surface free energy were carried out using an OCA15+ contact angle measuring device and the associated SCA 20 software (dataphysics GmbH), whereby each contact angle measurement value was averaged from ten measurements. The surface roughness of the CFRP components was determined using an MFP 3D-Classic atomic force microscope (Asylum Research Oxford Instruments Inc.) over 10 x 10 µm2 measuring areas. The X-ray photoelectron spectroscopy (XPS) measurements for element-specific analysis of the CFRP surfaces were carried out with an Axis Ultra DLD (Kratos Analytical Ltd.) and using a monochromatic X-ray source (Al Kα: 1468.6 eV).

Results and discussion

Fig. 1: Wettability of the treated CFRP components with water Figure 1 shows wettability results using the example of the static contact angle of water droplets that were placed on the treated CFRP surfaces.

Fig. 1: Wettability of the treated CFRP components with water Figure 1 shows wettability results using the example of the static contact angle of water droplets that were placed on the treated CFRP surfaces.

All processes show a significant improvement in wettability with water in some cases. In particular, the coating processes (e.g. T-Spot SiOx and Pyrosil®) lead to contact angles of only ten degrees and less, which can be attributed to the increased density of OH groups in the coatings and the slightly increased roughness of the surfaces.

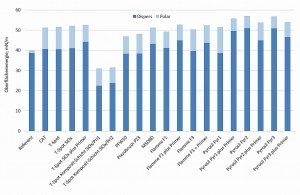

By using other liquids (ethylene glycol, thiodiglycol, diiodomethane) and analyzing their droplets, the free surface energy of the treated surfaces could be calculated using the method according to Owens, Wendt, Rabel and Kaelble. The surface free energy is split into a polar component and a disperse component.

Fig. 2: Surface energy of the treated CFRP components Figure 2 graphically shows the surface energies of the treated CFRP components determined on this basis. It can be seen from this figure that pre-treatment not only improves wettability with water, but also generally increases the polar component of the surface energy. Compared to water wettability, however, the coating processes no longer show such a clear difference compared to the non-coating processes. On the contrary: the two composite coatings deposited by means of T-spot lead to a reduction in the disperse portion of the surface energy to such an extent that the total free surface energy is even lower compared to the untreated reference samples. In the context of the high contact angles observed, this can be attributed to an overall higher organic content in the coatings compared to the two TIGRES-T spot coatings and the Pyrosil® coatings. Surface energy values of over 57 mN/m were achieved for some of the pre-treatment methods used.

Fig. 2: Surface energy of the treated CFRP components Figure 2 graphically shows the surface energies of the treated CFRP components determined on this basis. It can be seen from this figure that pre-treatment not only improves wettability with water, but also generally increases the polar component of the surface energy. Compared to water wettability, however, the coating processes no longer show such a clear difference compared to the non-coating processes. On the contrary: the two composite coatings deposited by means of T-spot lead to a reduction in the disperse portion of the surface energy to such an extent that the total free surface energy is even lower compared to the untreated reference samples. In the context of the high contact angles observed, this can be attributed to an overall higher organic content in the coatings compared to the two TIGRES-T spot coatings and the Pyrosil® coatings. Surface energy values of over 57 mN/m were achieved for some of the pre-treatment methods used.

As important as the assessment of surface properties with regard to wettability and surface energy is, investigations into adhesion strength are crucial for process control. With this in mind, the pre-treated, bonded (DP460) and artificially aged (72 h water storage at 80 °C) samples were examined using tensile shear strength testing in accordance with DIN EN 1465.

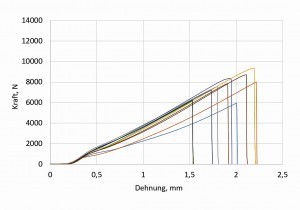

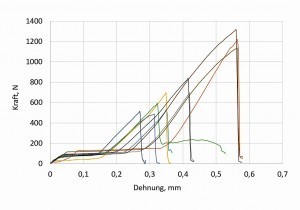

Figure 3 shows examples of force-strain curves for reference samples and for samples with uncoated (T-spot) and coated (T-spot SiOx + primer) pre-activation steps. The force-strain curves of the pure pre-activation (T-spot) show a significant reduction in the scatter of the measurement curves compared to the samples that had been bonded without pre-treatment. This tends to be the case for most pure pre-treatments and is also reflected in the standard deviations when determining the adhesion values. It can also be seen that the maximum achievable tensile forces for the coating process are around one order of magnitude lower.

Fig. 3: Force-strain curves for reference samples and for samples with uncoated (T-spot) and coated (T-spot SiOx + primer) pre-activation step. Note: In the latter representation, the force axis is shown one order of magnitude lower

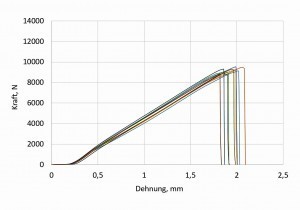

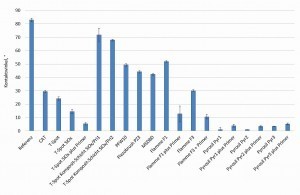

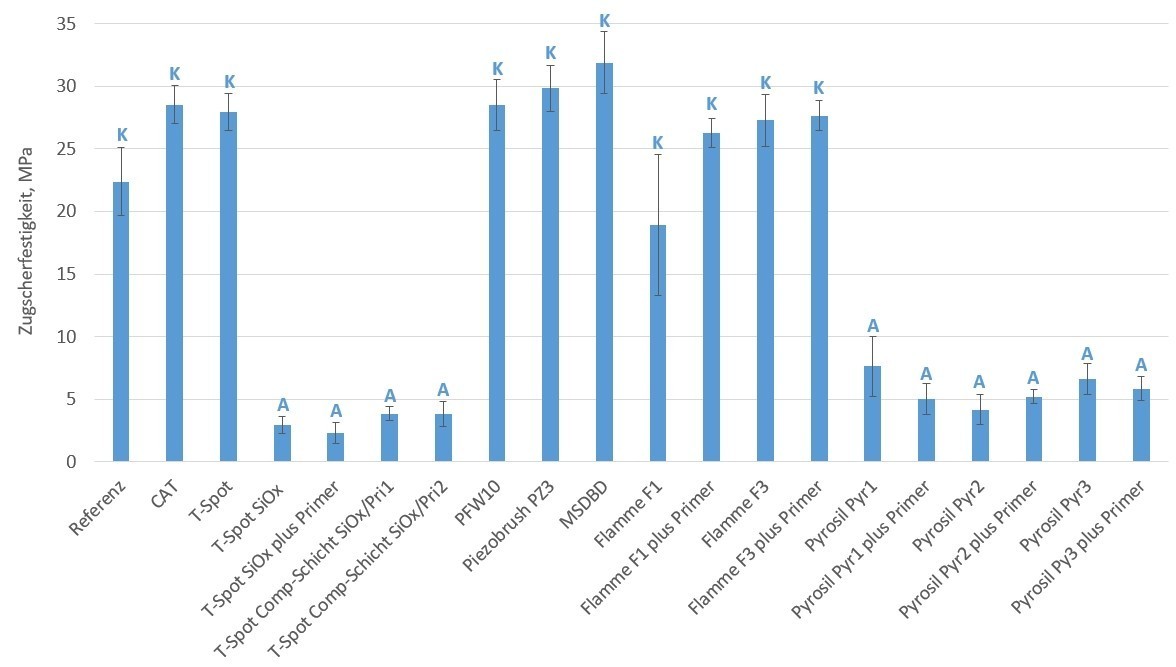

The adhesive strength values shown below were averaged from ten tensile strength tests each; Figure 4 shows the results of all tensile shear tests accordingly.

Even with the non-pretreated CFRP samples, very good adhesive strength values in the range of approx. 22 MPa were achieved. While pure flame treatments, depending on the selected treatment parameters, did not result in any major improvements in adhesive strength, these values were in some cases significantly exceeded by the atmospheric plasma pre-treatments. In particular, the pre-treatment processes based on a barrier discharge (Piezobrush PZ3, MSDBD) resulted in adhesion improvements of between around 20 and 45 % compared to the untreated reference samples. In all these samples, only cohesive fractures were observed in the adhesive used in accordance with DIN EN ISO 10365; there were no adhesion failures in the boundary layer between the CFRP component and the adhesive used.

Fig. 4: Tensile shear strength of bonded and then artificially aged CFRP test specimens, A - adhesive failure, K - cohesive failure, adhesive: ScotchWeld DP460, load: 72 h water storage at 80 °C

Fig. 4: Tensile shear strength of bonded and then artificially aged CFRP test specimens, A - adhesive failure, K - cohesive failure, adhesive: ScotchWeld DP460, load: 72 h water storage at 80 °C

The increase in adhesive strength can be explained by the incorporation of new functional groups in the areas near the surface of the CFRP material. Based on the results of the adhesion tests, an uncoated plasma and flame treatment (T-spot, flame F3) were selected for photoelectron spectroscopy studies (XPS) in addition to the untreated reference and corresponding samples were prepared. The evaluation of the measured overview spectra revealed a shift in the element-specific concentrations of carbon, oxygen and nitrogen in such a way that the proportion of oxygen on the CFRP surface increased from originally around 14.5 % to 18.6 % (T-spot) and 25.7 % (flame F3). In addition, the proportion of nitrogen-containing groups tripled to around 7.0 % as a result of plasma treatment with air as the reaction gas; as expected, the nitrogen content in the epoxy surface changed only slightly after flame treatment.

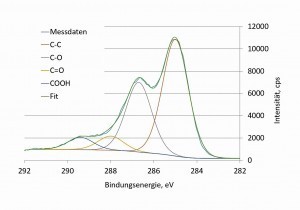

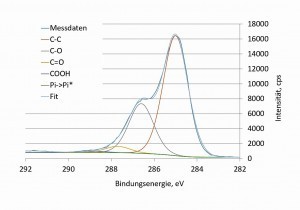

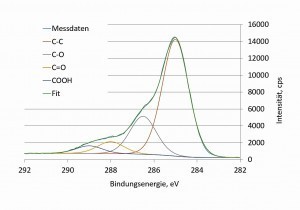

Figure 5 shows the XPS detail spectra of the carbon signal for an untreated reference sample as well as for T-spot and flame-treated samples, i.e. for two pre-treatments in which cohesive fractures with high adhesion values were observed. These detailed investigations allow conclusions to be drawn about the binding ratios of the carbon and thus about the type of functional groups that were formed on the surface as a reaction of the pre-treatment.

Fig. 5: Carbon XPS detail spectra for an untreated, a T-spot and a flame-treated CFRP sample (all processes non-coating)

The quantitative evaluation of the detail spectra for the plasma-pretreated CFRP surface showed that with an almost equal proportion of C-C bonds (approx. 67 %), the proportion of C=O double bonds doubled (approx. 7 %) to the detriment of the C-O single bonds. The significant increase in carboxyl groups to almost 5 % was also significant. For the flame-treated sample, on the other hand, a significant reduction in C-C single bonds to approx. 55 % was observed, while the proportion of C-O single bonds, C=O double bonds and carboxyl groups increased after flame treatment (corresponding to 32.8 %, 6.6 % and 5.7 %).

Fig. 6: Example of top: cohesive fracture failure (flame treatment F3, fracture in the adhesive) and bottom: adhesive fracture failure (T-spot SiOx, fracture in the adhesive/CFRP component interface) A second important result that emerges from the analysis of the bond strength tests (see Fig. 4) is the significantly reduced bond strength values for the samples that were coated using atmospheric plasmas or the flame treatment technique. As soon as a silicate intermediate layer was applied to the CFRP material prior to bonding, supposedly to improve adhesion, the bond strength values of the composites dropped dramatically in some cases! It did not matter whether a primer was used in addition to the SiOx intermediate layer or not. The reduction in the adhesive strength values is also accompanied by the occurrence of exclusively adhesive fracture failure in the adhesive/CFRP component interface (see Fig. 6)

Fig. 6: Example of top: cohesive fracture failure (flame treatment F3, fracture in the adhesive) and bottom: adhesive fracture failure (T-spot SiOx, fracture in the adhesive/CFRP component interface) A second important result that emerges from the analysis of the bond strength tests (see Fig. 4) is the significantly reduced bond strength values for the samples that were coated using atmospheric plasmas or the flame treatment technique. As soon as a silicate intermediate layer was applied to the CFRP material prior to bonding, supposedly to improve adhesion, the bond strength values of the composites dropped dramatically in some cases! It did not matter whether a primer was used in addition to the SiOx intermediate layer or not. The reduction in the adhesive strength values is also accompanied by the occurrence of exclusively adhesive fracture failure in the adhesive/CFRP component interface (see Fig. 6)

A quantitative XPS analysis of the silicon concentration at the interfaces allows conclusions to be drawn about the adhesion failure at the overlap point of the bond. For example, the Si concentration on a cured, pure DP460 adhesive surface was determined to be approximately 1.0 at%.

If the CFRP surface in the area of the bond after adhesion failure is considered, the Si concentration there is in a range between 1 and 4 at%, which is only slightly higher than on an untreated CFRP surface.

On the adhesive film itself, which is adhesively detached from the CFRP, there are Si concentrations in the range of 18 to 27 at% compared to the 1 at% mentioned for the pure DP460 adhesive. In this respect, the data suggest that, firstly, the applied SiOx layer can only be detected on the adhesive film and, secondly, the fracture must have occurred intrinsically in the SiOx layer, whereby the adhesion of the SiOx intermediate layer to the CFRP material is the actual problem and not the adhesion of the SiOx intermediate layer to the selected adhesive.

Correlations between wetting, surface energy, oxygen content and adhesion values

The question of the extent to which there are correlations between the wetting of a surface with an adhesive and the observed adhesion values of corresponding bonds is the subject of intensive discussion. For example, [3] points out that it has not yet been possible to calculate the strength of an adhesive bond from the interfacial energy values and that the wetting angle is not a measure of the level of bonding forces present at the interface. It is also explicitly emphasized in [4] that good wettability does not guarantee sufficient adhesion. This is also impressively reflected in the data shown above. However, [4] also points out that the increase in oxygen-containing functional groups resulting from plasma treatment correlates with an improvement in the adhesive strength of bonds. This is also shown by measurements on the temporal trend of the adhesive strength of PA6 composites and the surface tension, where these two properties correlate directly with the concentration of oxygen near the surface. This indicates a crucial role of the oxygen concentration for the bond strength [5]. Previous work has already pointed out the efficiency of various pretreatment processes with regard to the adhesion of coatings on various plastics; in addition to the actual pretreatment, the focus was also on investigations into the long-term stability of the pretreatments [6, 7].

Specifically addressing the bonding of CFRP components, it was shown that atmospheric plasma pretreatments are suitable for bringing about a significant improvement in adhesion. However, no quantitative correlation was shown here between the water wetting angle or the surface energy on the one hand and the measured bond strength on the other as a function of the specific pre-treatment parameters (plasma power, treatment time, distance) [8].

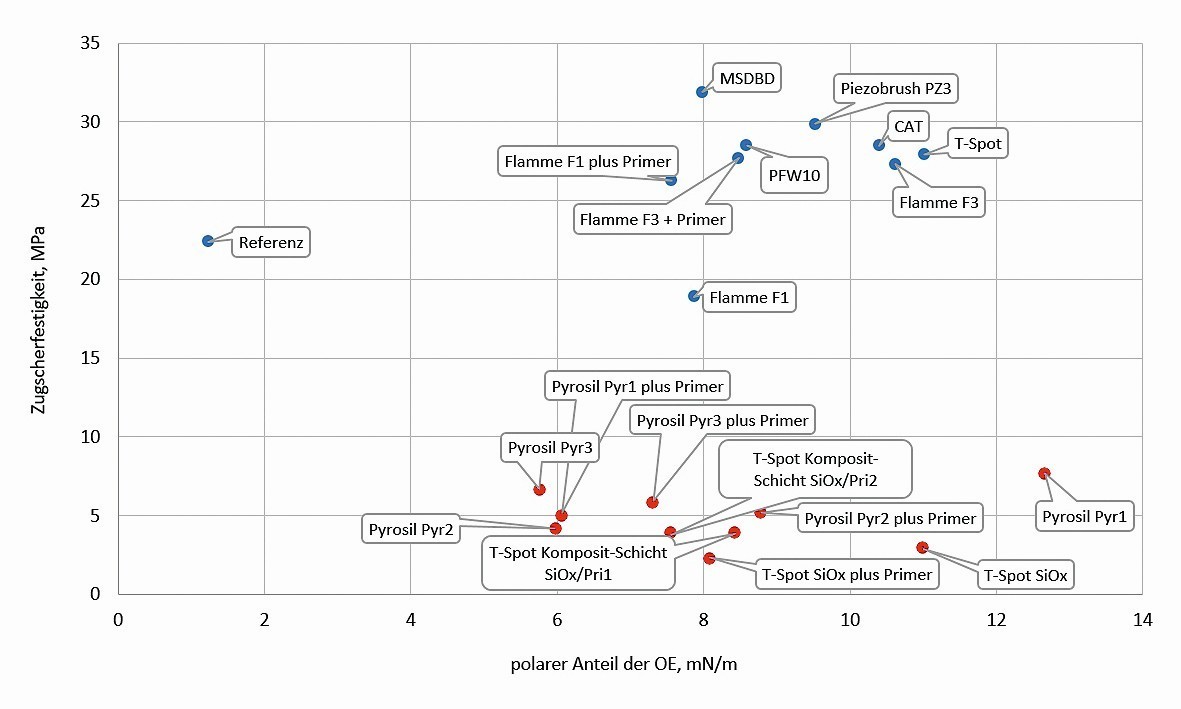

From the data available here for determining the wettability and surface energy (see Figs. 1 and 2), it can be seen that all pretreatment methods led to an increase in the polar component of the surface energy, and this in a relatively limited range between approx. 6 mN/m and 12 mN/m. At the same time, however, the values for water wettability scatter over a wide range between less than 5° and more than 70°! For example, the pretreatments using MSDBD and T-Spot SiOx + Primer result in an equally large increase in the polar component of the surface energy of around 8 mN/m, but the plasma-treated surface is significantly more hydrophobic!

Figure 7 allows a comparison of the pretreatments by showing the polar part of the surface energy and the observed adhesive forces. In the graph, the pairs of values for the non-coating pretreatment methods are shown in blue, for the coating methods in red. Although the polar components of the surface energy for the individual methods are in similar value ranges, the adhesion values for the two groups differ significantly. Moreover, if we only look at the blue pairs of values, there is no direct correlation between the polar component of the surface energy and the adhesion values, even for the pure pre-treatment methods.

Fig. 7: Comparison of the pre-treatments by displaying the polar component of the surface energy and the tensile shear strength (blue: pure activations, red: layer-forming processes)

Fig. 7: Comparison of the pre-treatments by displaying the polar component of the surface energy and the tensile shear strength (blue: pure activations, red: layer-forming processes)

Additional XPS investigations were carried out on the treated surfaces for the non-coating pre-treatment processes, i.e. for the pure plasma activations and flame treatments. The aim was to determine the oxygen content on the one hand and the binding states of the carbon in the surfaces on the other, and then to view these in the context of the observed adhesion values.

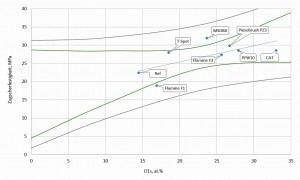

Figure 8 compares the oxygen concentrations in the CFRP surfaces determined from the XPS overview spectra with the averaged adhesion values of the corresponding bondings. While a correlation of the adhesion values with the polar components of the surface energy could not be observed, a more or less pronounced direct correlation can be seen with regard to the oxygen content in the CFRP surfaces: the higher the oxygen content in the surface generated by the pre-treatment, the better the adhesion of the composites. The analysis of variance (ANOVA) can be used to identify more precise information about the correlations behind the measurement data. The statgraphics Centurion XVII software was used for the calculation. In the analysis of variance performed, the significance value (p-value) exceeds 0.05, so there is no statistically significant relationship between the oxygen content at the surface and the tensile shear strength at a confidence level of 95% or higher. However, the correlation coefficient of theR2 statistic shows a moderate (linear) dependence between tensile shear strength and oxygen content. The majority of the values are within the confidence limits (green).

Summary and outlook

Fig. 8: Comparison of the oxygen content in the surface of the pre-treated CFRP material with the average tensile shear strength of the corresponding composites. The green lines correspond to the confidence limits, the gray lines correspond to the confidence limits The key message from these (and previous) studies is certainly that sufficient wetting of the surface is important for bonding, and corresponding contact angle tests are therefore very useful. However, the user should bear in mind that process development and control should always be supported by adhesion tests!

Fig. 8: Comparison of the oxygen content in the surface of the pre-treated CFRP material with the average tensile shear strength of the corresponding composites. The green lines correspond to the confidence limits, the gray lines correspond to the confidence limits The key message from these (and previous) studies is certainly that sufficient wetting of the surface is important for bonding, and corresponding contact angle tests are therefore very useful. However, the user should bear in mind that process development and control should always be supported by adhesion tests!

Specifically for the bonding of CFRP components, it has been shown that atmospheric pressure plasma or flame pre-treatment increases the wettability of the CFRP surface with water (even significantly in the case of coatings); in all cases, the polar component of the surface energy of the treated CFRP component also increases significantly.

A pure atmospheric pressure plasma or flame treatment leads to an improvement in the adhesion of bonded CFRP components, by a maximum of around 45%. Only cohesive fractures in the adhesive were observed. The pre-treatments also result in an improved uniformity of the bond, the standard deviations in the determination of the adhesive strength values decrease. The Piezobrush PZ3 system and the MSDBD show very good effects with relatively low plasma power input into the workpiece. In view of the low air throughput and the associated low emission of pollutants (ozone, nitrogen oxides), these processes are also advantageous. There is no correlation between increased surface energy and improved adhesion; on the other hand, it has been shown that the tensile shear strength is directly related to the oxygen content in the pre-treated CFRP surface. In the case of pure flame pre-treatment, the use of a primer only has a limited influence on improving adhesion, depending on the specific treatment parameters.

The use of an actual adhesion-promoting intermediate layer, deposited by flame or atmospheric pressure plasma, dramatically reduces the adhesion of the bonded CFRP components, although high polar proportions of the surface energy were also determined for these coating pre-treatments. Only adhesion fractures were observed in these bonds. Failure occurred in the SiOx interlayer and primarily near the CFRP surface; the silicon was detected both on the adhesive side (18 to 27 at%) and on the CFRP side (1 to 4 at%). Due to the limited adhesion of the SiOx interlayer to the CFRP material, the use of a primer in addition to the SiOx does not bring any further improvement.

Acknowledgments

The authors would like to thank K. Höse and S. Hartmann for their technical support in the realization of this study. The authors would also like to thank TIGRES GmbH for the loan of the T-Spot and the CAT system.

Literature

[1] N. Stephan: Lightweight construction in the commercial vehicle industry, study by the Chair of Mechanical and Apparatus Engineering at the Technical University of Kaiserslautern, 2014, https://www.cvc-suedwest.com/wp-content/uploads/2020/02/Publikation_Leichtbau-in-der-NFZ-Industrie_2014-1.pdf (accessed on 19.10.2021)

[2] M. Sauer: Composites United e.V., Composites Market Report 2020 Global CF - Production Capacities, January 2021, https://composites-united.com/wp-content/uploads/2020/01/GER_CUeV_Marktbericht_2020_CFCap.pdf (accessed on 19.10.2021)

[3] G. Habenicht: Adhesive bonding - basics, technology, applications. 6th updated edition. Springer Verlag Berlin Heidelberg, 2008, 348

[4] M. Lake: Surface technology in plastics processing - pre-treatment, coating, printing, functionalization, testing, 2nd edition. Munich: Carl Hanser Verlag, 2016, 57

[5] R. Wilken et al.: Pretreatment of plastics, In: Doobe M. (eds) Kunststoffe erfolgreich kleben, Springer Vieweg, Wiesbaden, 2018, 75, https://doi.org/10.1007/978-3-658-18445-2_2

[6] A. Pfuch; S. Schiemann; I. Erler; A. Heft; A. Schimanski: Tear test for the paint, Kunststoffe 3/2007, 30-34

[7] A. Pfuch; S. Schiemann; I. Erler; A. Schimanski: Between pretreatment and coating, Kunststoffe 06/2008, 82-86

[8] O. Reichelt: Plasma surface treatment of CFRP to improve the adhesive bonding properties, Master's thesis, Hamburg University of Applied Sciences, 2017