The investigations presented are an excerpt from a research project dealing with the use of atmospheric pressure plasma technology for primer application in the lamination of PVC window profiles. The project showed that it is possible to bond a plasma polymer coating to the PVC surface without swelling. The plasma pre-treatment prior to the actual plasma coating is a decisive process step here. If adhesion is optimized, it is possible to laminate plasma-coated PVC substrates that have the strength required by the industry after removal from storage. Replacing the wet-chemical primer application with the plasma process therefore appears possible in principle.

Introduction

PVC (polyvinyl chloride) window profiles are often laminated (wrapped) with film for visual design purposes. Compared to pure profile extrusion, film lamination offers a much wider range of decorative options. Colored or textured films are used to enhance the visual and tactile perception of vinyl windows. For example, windows can be produced that combine the value of a wooden window (feel, high surface quality, etc.) with the positive properties of a PVC window (price, weather resistance, low maintenance, etc.). However, the requirements for the adhesion of the cladding are very high with the required service life of the windows of approx. 50 years and permanent outdoor use [1]. The current state of the art in laminating window profiles is the use of primers on a wet-chemical basis. In 2016, the industry association Gütegemeinschaft Kunststoff-Fensterprofile (GKFP) drew up a guideline for industrial application [2]. However, this wet-chemical approach is associated with problems in the areas of occupational health and safety (exhaust air, labelling requirements for primers, etc.) and process control (reliability, complexity of the process, etc.).

As there is currently no practicable alternative to replacing primers, a research project at IFAM and SKZ investigated whether atmospheric pressure plasma can be used to deposit coatings that could be considered as an alternative to using primers. The coatings are deposited using plasma nozzles by means of plasma polymerization.

Plasma activation and coating

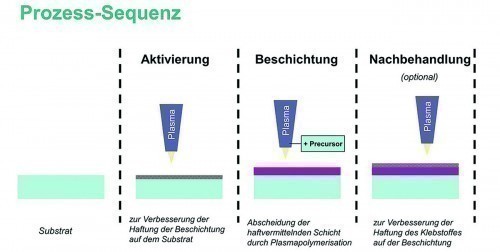

Plasma processes at atmospheric pressure are currently mainly used to activate surfaces in production, where they are widely used [3]. A typical application example is plasma activation prior to bonding in the automotive sector [4, 5]. Recently, plasma jet sources have also been used to deposit functional coatings by plasma polymerization at atmospheric pressure [6-9]. In plasma polymerization, a monomer (precursor) is fragmented in a plasma. For this purpose, the precursor is mixed into the plasma at the nozzle outlet. Some of the resulting fragments are then deposited on the substrate and re-crosslinked (see Fig. 1). By changing the process parameters (such as gas flow, type and quantity of precursor, plasma excitation conditions, etc.), coatings with different properties can be deposited [10].

Typically, the same or another plasma nozzle is used before the actual coating to activate the substrate surface first. This improves the adhesion of the coating to the substrate. For this process, the plasma nozzle is operated without precursor supply. Similarly, once the coating has been applied, the deposited coating can be (re-)activated in a further process step, e.g. to improve the adhesion of an adhesive to the coating (see Fig. 2).

Bonding PVC

Bonding to rigid PVC, which is used in typical window profile formulations, places high demands on pre-treatment due to the special characteristics of the material. The special material properties include the molecular structure and chemical composition as well as the high degree of additives added.

| Element | PVC window formulation (at.-%) |

Pure PVC (at.-%) |

| C | 78,4 | 66,6 |

| O | 9,2 | |

| Cl | 9,2 | 33,3 |

| N | 0,3 | |

| Si | 0,6 | |

| Zn | 0,3 | |

| Ca | 1,2 |

Tab. 1: Results of the XPS analysis of a typical surface of a PVS window profile compared to pure PVC

Table 1 shows the chemical analysis of the PVC surface using XPS (photoelectron spectroscopy). While chemically pure PVC theoretically has a chlorine content of 33.3 at.-%, the analysis of a commercial window profile formulation shows a significantly higher carbon content and a correspondingly lower chlorine content. This is due to the addition of carbon-containing substances (e.g. lubricants or impact modifiers). These additives are also present on the surface and can also accumulate there due to migration effects, which can have a considerable influence on the bond.

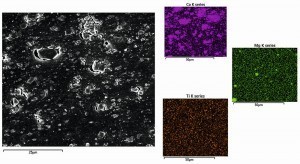

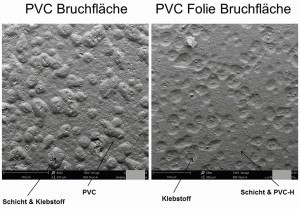

In addition to molecular additives, particulate additives are also observed. Figure 3 shows a scanning electron micrograph of a PVC surface. In an EDX analysis, particles containing titanium, calcium and magnesium of different sizes and distributions can be clearly seen, indicating the presence of other additives and fillers in the PVC formulation (chalk, UV stabilizers, etc.).

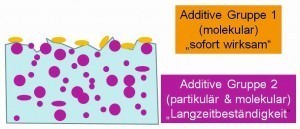

While the molecular additives have a direct influence on adhesion, the particulate additives are often important for the long-term stability of the bond, as migration effects driven by time and temperature play a role here (Fig. 4).

Typical primers create a reliable adhesion on such PVC surfaces by cleaning the surface and also swelling it. With plasma coatings, however, other effects are to be expected due to a different active principle and a different chemical composition, which are discussed below.

Plasma coating on PVC

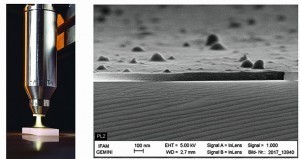

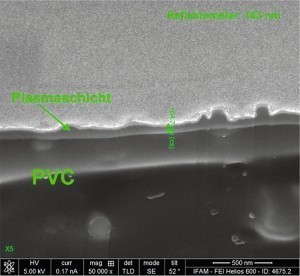

Figure 5 shows a plasma nozzle used in the project and a plasma layer deposited with it with a thickness of approx. 100 nm. An organosilicon precursor was used to deposit the layer.

Pretreatment is a decisive step for the adhesion of the plasma layer to the PVC. Therefore, both the chemical and topological changes of the PVC surface after pretreatment with different plasma intensities were analyzed. A typical way to vary the plasma intensity is to vary the treatment distance between the plasma nozzle and the substrate.

| Element | Pre-treatment 1 (at.-%) |

Pre-treatment 2 (at.-%) |

| C | 56,1 | 55,4 |

| O | 30,4 | 30,7 |

| Cl | 7,4 | 7,2 |

| N | 4,6 | 4,1 |

| Ca | 1,0 | 1,2 |

Tab. 2: Results of the XPS analysis of a PVC surface after pretreatment with two different parameter sets

Table 2 shows the result of the XPS analysis of a PVC surface after the pre-treatment step. There are considerable changes in the element composition on the surface as a result of the pre-treatment (see Table 1). In particular, the incorporation of oxygen and a decrease in the carbon concentration are observed, regardless of the degree of pre-treatment selected here. This is due to the removal and modification of molecular additives on the surface.

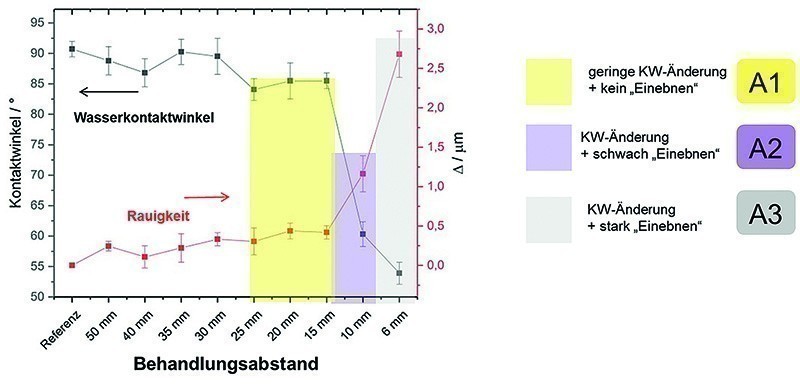

Fig. 6: Influence of the pre-treatment on the water contact angle and the roughness of the PVC

Fig. 6: Influence of the pre-treatment on the water contact angle and the roughness of the PVC

Figure 6 also shows the water contact angle and the change in roughness as a function of the treatment distance. In order to determine the change in roughness, an artificial trench was created on the PVC surface in advance and measured using profilometry. Figure 6 shows the decrease in trench depth ∆ after the respective pre-treatment. Depending on the pre-treatment intensity, which was set here by varying the treatment distance, three different regimes can be identified. In range A1 (less intensive pre-treatment), there are slight changes in the contact angle and surface roughness is not leveled, while in range A3 (intensive pre-treatment), strong changes can be observed for both variables. A2 represents a transition area. The associated process parameters for these three areas are labeled A1, A2 and A3. They represent three different regimes of activation intensity, which lead to different surface modifications.

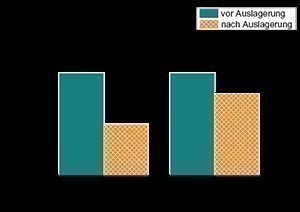

Based on this, the influence of the pre-treatment on the adhesive strength was investigated in extensive studies using the peel resistance of the adhesive bond. For this purpose, roll peel samples were produced by bonding the PVC substrates with laminating film using a typical 1-component PU hotmelt adhesive. Furthermore, ageing tests were carried out on the samples in order to evaluate their resistance to the effects of moisture and temperature. The aging tests were carried out for 42 d at 70 °C and 95 % RH.

Fig. 7: Peel resistance before and after aging as a function of pre-treatment intensity for the same coating. The type of fracture is also indicated (see Fig. 8)

Fig. 7: Peel resistance before and after aging as a function of pre-treatment intensity for the same coating. The type of fracture is also indicated (see Fig. 8)

Figure 7 shows an example of the peel resistance as a function of the pre-treatment intensity. As this figure shows, intensive pre-treatment in parameter range A3 is best suited for high peel resistance, especially after ageing.

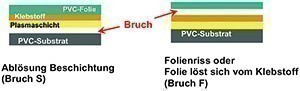

Fig. 8: Schematic representation of possible fracture patterns when testing coated PVC samples with laminated film

Fig. 8: Schematic representation of possible fracture patterns when testing coated PVC samples with laminated film

The fracture pattern is always important for evaluating the adhesive results. As shown schematically in Figure 8, different failure patterns can occur during the test. The fracture pattern "F", in which failure occurs in the area of the laminated film, is desirable for the application. This is the case here with more intensive pre-treatment.

Breakage failure with poor pre-treatment

Insufficient pre-treatment, on the other hand, results in an uneven and therefore more complex fracture failure. Figure 9 shows the fracture surfaces in a low-intensity pre-treatment step. In this case, an inhomogeneous fracture failure can be observed in the interfaces. Instead of a film tear or detachment of the film from the laminating adhesive, there is alternating failure near the interface in the PVC and in the adhesive. The plasma coating is partially present on both fracture surfaces. This complex behavior clearly shows the role that the additives and their distribution as well as the intensity of the pre-treatment can play in adhesion to PVC.

In this context, it is also interesting to see how the plasma coating is bonded to the PVC surface with optimum pre-treatment. Figure 10 shows a cross-sectional scanning electron micrograph of the coated PVC surface. There are no signs of adhesion of the coating due to swelling. The adhesion of the coating therefore appears to be based predominantly on inter- and intramolecular interactions (e.g. Lewis acid-base interactions).

Conclusion:

As the excerpted project results show, it is possible to bond the plasma-polymer coating to the PVC surfaces without swelling. The decisive process step is the plasma pre-treatment before the actual plasma coating. In the case of optimum adhesion, it is then possible to laminate plasma-coated PVC substrates that have sufficient strength after the ageing process required by the industry. Replacing wet-chemical primer application with the plasma process therefore appears possible in principle. However, further investigations are required before this technology can be used commercially, particularly with regard to the pre-treatment step and the influence of different additives.

Plasma-based application at atmospheric pressure can represent a considerable improvement on conventional process technology. In particular, it is an alternative to minimize the use of hazardous chemicals in industrial production and to increase the degree of automation in production, for example by eliminating the need to change primer-impregnated application felts.

Acknowledgments

The project 19347 N of the research association "Dechema: Gesellschaft für Chemische Technik und Biotechnologie", Frankfurt, was funded by the Federal Ministry for Economic Affairs and Energy (BMWi) via the German Federation of Industrial Research Associations (AiF) as part of the program for the promotion of joint industrial research and development (IGF) on the basis of a resolution of the German Bundestag.

Literature

[1] Glas+Rahmen, Boost for energy efficiency, 01/2016, p. 39

[2] RAL-Gütegemeinschaft Kunststoff-Fensterprofilsysteme e.V., Process-safe lamination of window profiles - A technical guide, 2016

[3] C. Tendero; C. Tixier; P. Tristant;, J. Desmaison; P. Leprince: Atmospheric pressure plasmas: a review, Spectrochim. Acta Part B, 61, 2006, 2-30

[4] M. Noeske; J. Degenhardt; S. Strudthoff; U. Lommatzsch: Plasma jet treatment of five polymers at atmospheric pressure: surface modifications and the relevance for adhesion, International Journal of Adhesion and Adhesives, 24, 2004, 171-177

[5] Plasma coating integrated into the process, JOT Spezial Korrosionsschutz, 36, 2008

[6] U. Lommatzsch; J. Ihde: Plasma polymerization of HMDSO with an atmospheric pressure plasma jet for corrosion protection of aluminium and low-adhesion surfaces, Plasma Proc. Polymers, 6, 2009, 642

[7] P. Bringmann; O. Rohr; F.J. Gammel; I. Jansen: Atmospheric pressure plasma deposition of adhesion promotion layers on aluminum, Plasma Process. Polym., 6, 2009, 496

[8] J. Pulpytel; V. Kumar; P. Peng; V. Micheli; N. Laidani; F. Arefi-Khonsari: Deposition of organosilicon coatings by a non-equilibrium atmospheric pressure plasma jet: design, analysis and macroscopic scaling law of the process, DOI: 10.1002/ppap.201000121

[9] Y. Sawada; S. Ogawa; M. Kogoma: Synthesis of plasma-polymerized tetraethoxysilane and hexamethyldisiloxane films prepared by atmospheric pressure glow discharge, Journal of Physics D: Applied Physics, 28, 1995, 1661

[10] H. Yasuda: Plasma polymerization, Orlando, 1985