The cleaning of pre-drawn and annealed wire is usually carried out with electrolyte pickling or in an ultrasonic bath. How cleaning with high-pressure steam and additional electrical charge performed in comparison is the subject of the 10th installment of the cleaning series.

Test description of external surfaces - dirt and stearate removal on wire with high-pressure steam on a running solid wire surface

Fig. 1: HP steam nozzle for aluminum wire Clean and scale-free surfaces are the basis for coating pre-drawn and annealed wire. The pre-drawn wire material is drawn to the required diameter in up to 13 stages using drawing soaps, usually stearates. The stearates become a chemically insoluble layer around the wire due to the heat generated during the drawing process.

Fig. 1: HP steam nozzle for aluminum wire Clean and scale-free surfaces are the basis for coating pre-drawn and annealed wire. The pre-drawn wire material is drawn to the required diameter in up to 13 stages using drawing soaps, usually stearates. The stearates become a chemically insoluble layer around the wire due to the heat generated during the drawing process.

The gas development of hydrogen and oxygen leads to the removal of the dirt coating from the wire surface. The electrolyte pickle, usually sulphuric acid plus direct current, removes the stearates from the wire surface. The hydrogen is produced on the wire surface and breaks open the shell. The pickled wire surface is electrically active, i.e. coatings adhere very well due to the electrical charge. Rinsing transports the blasted stearates into the rinsing bath. The hydrogen formed and released on the wire surface is essential for successful cleaning. Chemical processes only play a role in generating the hydrogen. It is known that electrolytically pickled wire rods can be drawn at three times the speed of mechanically brushed wires.

Another frequently used technology is cleaning in an ultrasonic bath. It can be assumed that free radicals are formed. Reactions limited to the smallest areas lead to an increase in temperature and pressure, resulting in the dissociation of the surrounding water molecules into H+ ions, OH ions and hydrogen peroxide.

The cavitation effect depends on the energy (amplitude) and (to a lesser extent) the frequency of the sound waves as well as the duration of the sonication. The intensity of ultrasonic waves is directly proportional to their amplitude.

Low frequencies around 20 kHz generate bubbles of larger diameter with powerful pressure surges compared to higher frequencies around 35 kHz, the amount of energy measured in watts/m². Here too, the hydrogen and the measurable electrical charge of the component surface are essential for the cleaning processes.

Based on these processes, which are known in practice, it made sense to try cleaning with high-pressure steam and an additional electrical charge. The number and thickness of the stearate layers were gradually increased. It was significant that the wire surfaces were cleaned with up to 2 % residual contamination. The use of electrolytically charged high-pressure steam was therefore tested in two test series together with a wire manufacturer.

To increase and control the cleaning effect, the outflowing steam is given a more positive electrical charge, i.e. the static DC voltage as an additional voltage increases the discharge effect of the steam molecules on the surface. Alternatively, the wire in the area of the HP nozzle is positively charged. The separation of the foreign particles from the surface takes place with a higher intensity. More hydrogen ions are released and blast off the stearate. The process is virtually dry, i.e. the small amount of moistening required before the HP nozzle evaporates immediately after the cleaning nozzle. Transporting the blasted off dirt particles from the wire surface thus becomes a technical challenge.

Here is an example equation for the amount of dirt produced:

Wire diameter 1.5 mm x 3.14 x 1000 mm

Wire length x 0.3 mm protective coating thickness from

Stearates → 1.4 cm3 of deposited dirt per meter of wire

meter of wire with layer thickness 0.3 mm <1>

Fig. 2: HP steam nozzle for surgical wiresMultiplyingthe feed rate of 1 m/sec results in dirt deposits of at least 84 cm3 per minute, at feed rates of 15 m/sec this is at least 1260 cm3, i.e. approx. 1.26 liters.

Fig. 2: HP steam nozzle for surgical wiresMultiplyingthe feed rate of 1 m/sec results in dirt deposits of at least 84 cm3 per minute, at feed rates of 15 m/sec this is at least 1260 cm3, i.e. approx. 1.26 liters.

In the tests, a wire speed of up to 35 m/sec was used. Up to 15 m/sec, the cleaning processes can be controlled for 3 hours. Then there are unresolved problems with the blasted stearates and their solutions in the condensation water of the collection tanks. Massive lumps form, the stearates precipitate and stick to the walls of pipes and baths. The pipe systems block. The first to block are the HP cleaner nozzles. We are working on a solution to these problems.

In all tests, the cleaning of the running wire from stearates or drawing oils was safe up to a running speed of 15 m/sec. If one calculates the dwell time of the wire surface in the direct HP nozzle area, clear nozzle gap is 0.05 mm with a following Venturi nozzle up to a length of 70 mm, it is fractions of a second. At 1 m/sec wire feed, 70 mm of wire to be cleaned is a maximum of 0.07 sec in the direct effective range of the HP nozzle. If the wire feed rate is increased to 15 m/sec, 70 mm of wire to be cleaned is in the direct effective range of the HP nozzle for a maximum of 0.005 sec. Tests with an extended Venturi nozzle using a cylindrical tube showed improvements in deposition. However, the deposited stearate cannot be sufficiently removed in the pipe extension. The tube clogs within a few minutes. The tests are described below and the findings on the processes are documented.

Tests with the addition of mordants and cleaners show no measurable or visible effects. The chemical processes cannot be set in motion during the very short reaction time. The electrical voltage on the component surface should be 2 to 3.5 volts DC. Higher voltages do not accelerate the process. Due to the contact resistances and the possible leakage currents in electrolytic pickling baths, a voltage of up to 20 volts is used. The test series in this work were carried out with voltages of 2 to 3.5 volts DC. Significant differences in the deposition results could not be demonstrated. Therefore, 2 to 2.5 volts were used in all test series.

Overview of the tests and test results

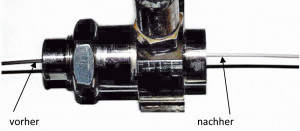

The first series of tests involved cleaning a solid aluminum wire with a wire diameter of 2.3 mm after rolling/drawing. The surface was heavily wetted with target oils. These had dried to a caked-on state on the surface as a result of the previous forming processes. The wire was surrounded by a layer of dirt. This dirt coating does not dissolve in plain water. As described, the dirt coating can only be removed by pickling. In the test with the HP steam nozzle, HP steam was directed onto the wire surface from 1 HP nozzle and from up to 3 HP nozzles in series. The double Venturi nozzle with pipe extension was used. Speeds of up to 1.5 m/sec were successfully tested. The cleaning results were sufficient (Fig. 1).

Fig. 3: HP steam nozzle for solid wire up to 1.5 mm wire diameter up to 5 m/sec wire feed speed, wire run from left to rightThesecond series of tests involved the cleaning of surgical wires, wire diameter 0.1 to 0.3 mm, as solid wire and as stranded wire. Wire speeds between 1 m/sec and 10 m/sec were tested. The nozzle from test series a was used for the tests. The clear diameter of the HP nozzle of 4 mm was not sufficiently small for this application in the clear nozzle diameter (up to 1.5 mm clear diameter required). Nevertheless, series of tests were carried out which showed a reliable trend in the cleaning results. The use of an HP nozzle with a clear diameter of 1.5 mm would be more meaningful, as the deposits would be much more intensive (Fig. 2).

Fig. 3: HP steam nozzle for solid wire up to 1.5 mm wire diameter up to 5 m/sec wire feed speed, wire run from left to rightThesecond series of tests involved the cleaning of surgical wires, wire diameter 0.1 to 0.3 mm, as solid wire and as stranded wire. Wire speeds between 1 m/sec and 10 m/sec were tested. The nozzle from test series a was used for the tests. The clear diameter of the HP nozzle of 4 mm was not sufficiently small for this application in the clear nozzle diameter (up to 1.5 mm clear diameter required). Nevertheless, series of tests were carried out which showed a reliable trend in the cleaning results. The use of an HP nozzle with a clear diameter of 1.5 mm would be more meaningful, as the deposits would be much more intensive (Fig. 2).

The third series of tests involved the cleaning of drawn welding wires with a diameter of 1.1 to 1.5 mm at running speeds of up to 35 m/sec (Fig. 3). This series of tests yielded the most evaluable results that enable the calculation of a cleaning system for wire. This test series is therefore used as the basis for calculations.

Technological parameters for successful wire cleaning of solid wire

The tests of the third test series were carried out in the wire production for welding wires of the company WDI. The welding wire is drawn in 13 stages, cleaned and then electrolytically copper-plated. The adhesion and the thickness of the copper coating on the cleaned wire surface are essential for the quality of the welding wires. This coating is only possible if the surface is free of surfactant grease. Less than 2 % foreign dirt is permitted. These values were achieved up to a wire speed of 15 m/sec.

Two different nozzle designs were used for the test series. The V2A nozzle was sufficient for removing the cleaned foreign matter up to a wire feed rate of 5 m/sec. The brass nozzle with additional nozzles for the removal of the cleaned foreign matter was used for all tests up to 15 m/sec wire feed.

The dry steam requirement for the cleaning tests is calculated from the following equations:

Clearance diameter 4 mm, annular gap of the

Venturi nozzle 0.05mm → 3.14 x 4 mm x 0.05 mm =

0.628 mm2 clear nozzle cross-section at

8 bar overpressure dry steam 200 °C <2>

Table 1 shows more details.

As the vapors are fed into the condensate collection tank by suction, fresh water requirements and heating energy are low. The bath temperature in the collection tank is kept at 80 to 90 °C. In intermittent operation, the steam generator heats with 11 kW heat output. In the tests, the average power requirement per hour was 4 kWh. As the design of the cleaning section only reduced heat losses to the environment to a limited extent, no loss calculations were carried out. The provision of the 80 to 90 °C hot condensate for refilling the steam generator was essential for the electrical output of the heating system. If the condensation conditions were optimal, the heating output was less than 4 kWh.

|

Property |

Value |

Unit |

|

Medium: |

Superheated water vapor |

|

|

Pressure: |

8 |

[ bar ] |

|

Temperature: |

200 |

[ Celsius ] |

|

Density: |

3.8333626692401 |

[ kg /m3 ] |

|

Dynamic viscosity: |

1.5957077607232E-5 |

[ Pa s ] |

|

Kinematic viscosity: |

4.162684041162 |

[10-6m2 / s] |

|

Specific internal energy: |

2631.0763359643 |

[ kJ / kg ] |

|

Specific enthalpy: |

2839.7703910349 |

[ kJ / kg ] |

|

Specific entropy: |

6.817616096585 |

[ kJ / kg K ] |

|

Specific isobaric heat capacity: Cp |

2.3030096903127 |

[ kJ / kg K ] |

|

Specific isochoric heat capacity: cv |

1.6837326907639 |

[ kJ / kg K ] |

|

Isentropic exponent: kappa |

1.3021 |

|

|

Thermal conductivity: |

0.036267364332136 |

[ W / m K ] |

|

Speed of sound: |

521.29272863866 |

[ m / s ] |

The tests were carried out without an additional voltage of 2.5 volts DC and with an additional voltage of 2.5 volts DC. The differences in deposition were visible. With additional voltage, the residual particles on the wire surface were less than 5 % by volume and almost free of carbon. Without additional voltage, the residual particles on the wire surface were less than 15 % by volume.

In all tests, the first traces of corrosion, flash rust, were visible on the steel wire within 5 minutes. The aluminum wire turned gray, like a layer of aluminum oxide.

In industrial plants, targeted passivation is therefore carried out immediately after high-pressure steam cleaning without an intermediate stop.

Designs for cleaning wire surfaces using superheated steam

Tests are underway to clean the wire surfaces of drawn steel wires up to drawing speeds of 35 m/s with integrated cleaning using galvanic high-pressure steam. The removal of the drawing soaps from the material surface takes place safely at these drawing speeds. Once the dissolved particles have left the wire surface, they float at their own speed towards the adjacent surfaces of the die and the chamber structure. Due to the quantity per time, high-pressure water is used as a rinsing agent. Due to the high impulse energy of the particles, experiments are carried out with water pressures of up to 1300 bar(atü). The tests for cleaning the wire surfaces of aluminum wire and medical wires, at thread speeds below 5 m/s, are successful. The parameters for these processes are subject to confidentiality.