Electroplating plastics without chromium(VI) - this is currently one of the biggest challenges facing the electroplating industry. For years, specialist companies have been working hard to find alternative ways to coat plastic components using Cr(VI)-free systems. In addition to numerous unsuccessful attempts to integrate new systems into existing plants, the industry is also faced with the current EU regulations, which must be complied with in a timely manner.

Fig. 2: Rackstar rack insulation systemNowadays,specialist companies can replace the familiar ABS stain made from a chromium-sulphuric acid mixture with manganese-containing or manganese-free stain systems. It is now known that the rack insulation and its processing have a major influence on the entire chrome-plating process, especially with regard to the rack coating. Since 2018, the author has consistently worked on various solutions to develop a new, modern rack insulation system. For example, the pre-treatment process can be integrated into existing systems without the use of swellers, rack protection and conditioners. Using the system developed, specialist companies and coaters can integrate the new Cr(VI)-free process into existing systems. Plastics and, in particular, multi-component plastics can still be electroplated without any problems for various branches of industry. Furthermore, the modern rack insulation system not only reduces or saves process and material costs, but also significantly reduces the burden on the environment.

Fig. 2: Rackstar rack insulation systemNowadays,specialist companies can replace the familiar ABS stain made from a chromium-sulphuric acid mixture with manganese-containing or manganese-free stain systems. It is now known that the rack insulation and its processing have a major influence on the entire chrome-plating process, especially with regard to the rack coating. Since 2018, the author has consistently worked on various solutions to develop a new, modern rack insulation system. For example, the pre-treatment process can be integrated into existing systems without the use of swellers, rack protection and conditioners. Using the system developed, specialist companies and coaters can integrate the new Cr(VI)-free process into existing systems. Plastics and, in particular, multi-component plastics can still be electroplated without any problems for various branches of industry. Furthermore, the modern rack insulation system not only reduces or saves process and material costs, but also significantly reduces the burden on the environment.

State of the art

Up to now, ABS, ABS/PC and PA made from Cr(VI)-containing mixtures have been pickled with chromic and sulphuric acid. ABS blanks are mounted on an electroplating frame that is coated with a PVC dip coating. The metal core of the frame is protected against acid attack. After successful pre-treatment, the ABS blank forms a perfect electrical contact. The components can be coated in various electrolytes under direct current.

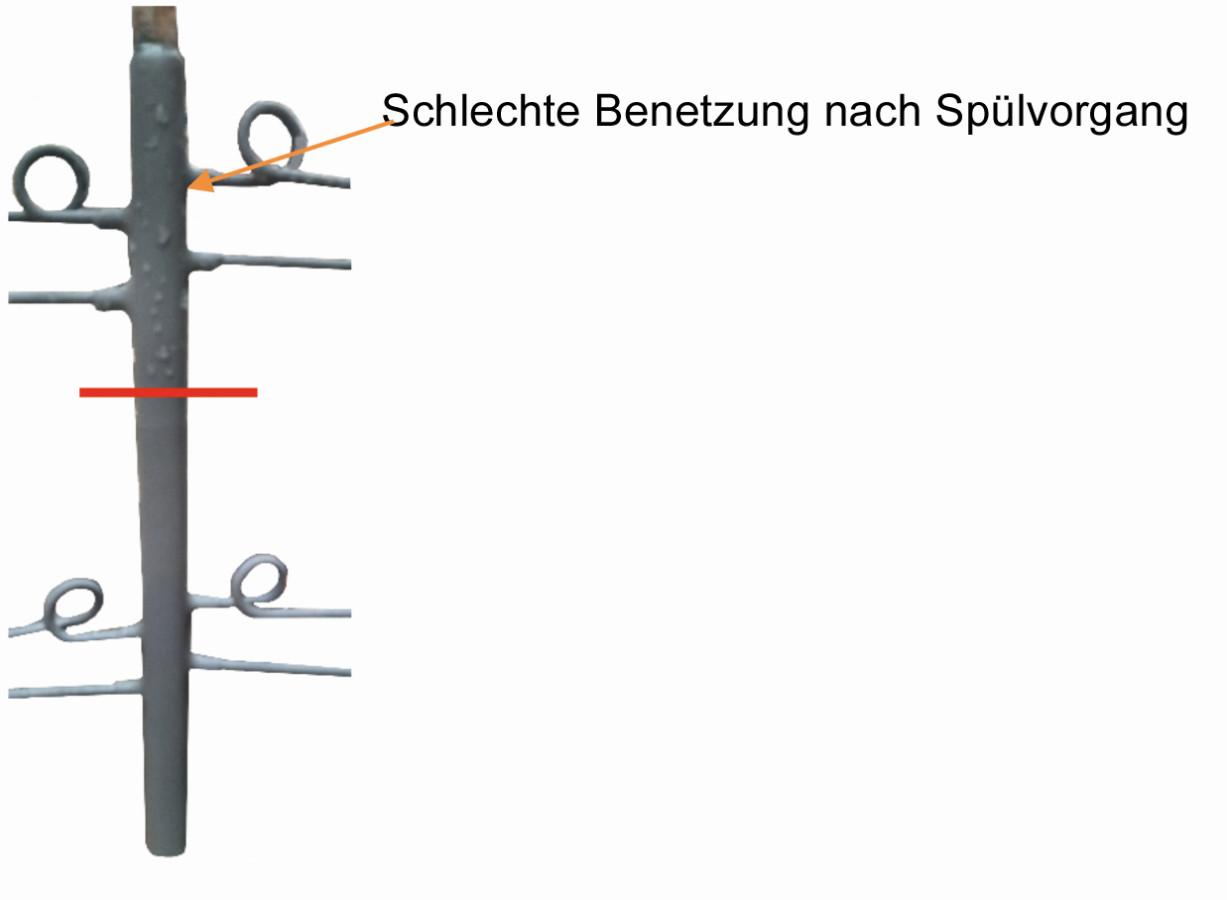

Fig. 3: Rackstar® after rinsing

Fig. 3: Rackstar® after rinsing

The PVC plastisol of the rack absorbs a lot of stain and allows the chrome compounds to penetrate. What causes this reaction? Subsequently after pickling - usually with palladium-tin colloids - the activation of the PVC plastisol is prevented under certain process conditions. The result: the prevention of frame metallization (Fig. 1).

What do current investigations show? The same reactions do not take place in the Cr(VI)-free pre-treatment process. Specialist companies have therefore developed rack protection to achieve the same effect. A negative side effect is that the pre-treatment process requires a conditioner so that the ABS blanks absorb the palladium-tin colloids and no open spots occur. These additional steps not only prolong the pre-treatment process, but also increase the consumption of palladium and the costs for the new batch plus disposal.

Structure of the rack insulation system

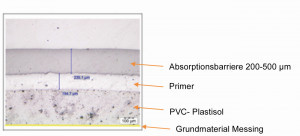

Fig. 4: Penetration colloid on the left and deposition colloid on the right The patented rack insulation system from the Rackstar series differs from conventional electroplating racks in the structure of the layer system. After successful pre-treatment, a special primer is applied to existing or new electroplating racks to ensure adhesion of the layers. In addition, an absorption barrier of 200-500 µm is applied, which consists of a fluoropolymer alloy in order to achieve specific properties. The composition of the frame insulation system is shown above in cross-section (Fig. 2).

Fig. 4: Penetration colloid on the left and deposition colloid on the right The patented rack insulation system from the Rackstar series differs from conventional electroplating racks in the structure of the layer system. After successful pre-treatment, a special primer is applied to existing or new electroplating racks to ensure adhesion of the layers. In addition, an absorption barrier of 200-500 µm is applied, which consists of a fluoropolymer alloy in order to achieve specific properties. The composition of the frame insulation system is shown above in cross-section (Fig. 2).

Layer hardness

The hardness of the layer in this system is greater than that of PVC plastisols in order to withstand expansion due to the high temperature of 70 °C in the chromium-free pickling process. The result is a higher thermal resistance in contrast to PVC plastisols, which minimize or even prevent the penetration of the stain. Table 1 and measurements show the results of the measured values.

|

Measurement |

Rackstar® Pro |

Rackstar® Premium |

PVC plastisol |

|

1 |

39,0 |

28,5 |

23,8 |

|

2 |

39,1 |

29,2 |

23,7 |

|

3 |

38,9 |

29,3 |

23,6 |

|

4 |

38,5 |

29,2 |

23,3 |

|

5 |

38,0 |

29,8 |

23,4 |

|

Average value |

38,8 |

29,2 |

23,4 |

Contact angle

In contrast to the ABS blank, the rack insulation should have poor or no wetting of the surface. The pickling attack and the adhesion of the palladium colloids are prevented or minimized and the carry-over of process chemicals is also avoided. This is achieved by a proportion of fluoropolymers.

Table 2 compares the respective contact angles. This shows that the Rackstar Premium rack insulation system has the highest contact angle and therefore the worst wetting properties of all the systems (Fig. 3).

|

Sample |

Contact angle in ° |

|||

|

Measurement |

1 |

2 |

3 |

Mean value |

|

PVC Plastisol |

80,2 |

81,1 |

80,7 |

80,7 |

|

Rackstar® Pro |

94,4 |

94,1 |

95,6 |

94,7 |

|

Rackstar® Premium |

114,5 |

109,0 |

113,6 |

112,4 |

Ultrasound (2 k blanks ABS/PC)

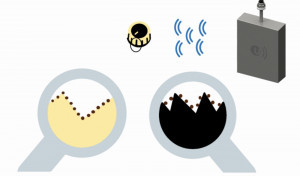

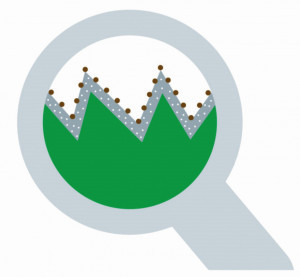

Fig. 5: Attachment colloid on Rackstar® Premium Based on the above-mentioned properties of the rack insulation system, further details now follow. The use of ultrasonic technology with a frequency of 40 Hz has a positive effect, provided that the pre-treatment is carried out using chromium-free systems. Firstly, the manganese dioxide produced is better rinsed out of the cavities of the blank after the chrome-free pickling process and allows a higher tolerance for 2 K electroplating. The PC component is more resistant in the pickling process than the ABS. A different cavern structure is achieved on the surface, which also has an effect on the subsequent activation of the plastic. A penetration colloid is formed on the ABS component during the germination process. Result: higher adhesion forces between ABS/palladium/tin. On the PC component, colloids are formed during the germination process, resulting in lower adhesion forces, which can easily be blown off by the cavitation forces generated by the ultrasound. As deposition colloids are also formed on the new rack insulation system and the high contact angle also produces a better rinsing effect, this opens up new opportunities for electroplating multi-component plastics from chrome-free pre-treatment systems. Figures 4 and 5 schematically illustrate this physical process on the 2 K component and the new rack insulation system.

Fig. 5: Attachment colloid on Rackstar® Premium Based on the above-mentioned properties of the rack insulation system, further details now follow. The use of ultrasonic technology with a frequency of 40 Hz has a positive effect, provided that the pre-treatment is carried out using chromium-free systems. Firstly, the manganese dioxide produced is better rinsed out of the cavities of the blank after the chrome-free pickling process and allows a higher tolerance for 2 K electroplating. The PC component is more resistant in the pickling process than the ABS. A different cavern structure is achieved on the surface, which also has an effect on the subsequent activation of the plastic. A penetration colloid is formed on the ABS component during the germination process. Result: higher adhesion forces between ABS/palladium/tin. On the PC component, colloids are formed during the germination process, resulting in lower adhesion forces, which can easily be blown off by the cavitation forces generated by the ultrasound. As deposition colloids are also formed on the new rack insulation system and the high contact angle also produces a better rinsing effect, this opens up new opportunities for electroplating multi-component plastics from chrome-free pre-treatment systems. Figures 4 and 5 schematically illustrate this physical process on the 2 K component and the new rack insulation system.

Early warning system

The absorption barrier can be checked simply and easily by specialist personnel at the plant without great effort in order to ensure the stability of the pickling process. The focus here is also on the amount of MnO2 produced, which must be oxidized back into MnO-7 by the oxomat. This is controlled by the use of fluorescence chemistry. The closed absorption barrier can be controlled between a wavelength of 460-500 nm. It is important to know that the absorption barrier minimizes the reduction to MnO2. Oxidation fluctuations can also be absorbed in the oxomat. The pickling process can be stabilized (Tab. 3 and Fig. 6).

|

Plastisol system |

Consumption of oxidizing agent |

|

Co-provider 1 PVC |

0,4-0,5 |

|

Co-provider 2 PVC with inhibitor |

0,05-0,07 |

|

Innovative system PVC/ F-CH |

0,005-0,007 |

Metal savings

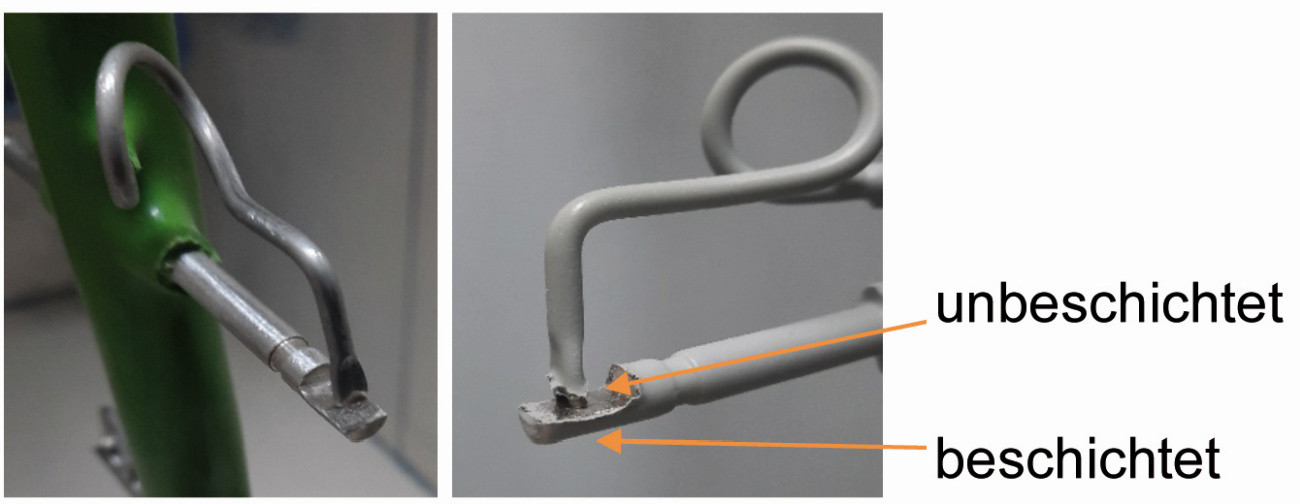

Fig. 6: Integrated early warning system in the rack insulation system at approx. 460-500 nm visualized with the Rackstar UV Lamp In today's world, it is more important than ever to save resources. Reducing metal consumption in the electroplating process is an enormous challenge, as raw materials are becoming increasingly scarce and expensive. The solution: adapting the plating process. In other words, only insulate the contact surface actually used in order to prevent metal deposition on the entire rack contact (Fig. 7).

Fig. 6: Integrated early warning system in the rack insulation system at approx. 460-500 nm visualized with the Rackstar UV Lamp In today's world, it is more important than ever to save resources. Reducing metal consumption in the electroplating process is an enormous challenge, as raw materials are becoming increasingly scarce and expensive. The solution: adapting the plating process. In other words, only insulate the contact surface actually used in order to prevent metal deposition on the entire rack contact (Fig. 7).

The result: Savings of several tons of copper and nickel anodes. No additional precipitation of unnecessarily deposited metal in the wastewater plant due to demetallization, which ultimately causes the expensive disposal of metal sludge and the consumption of wastewater chemicals.

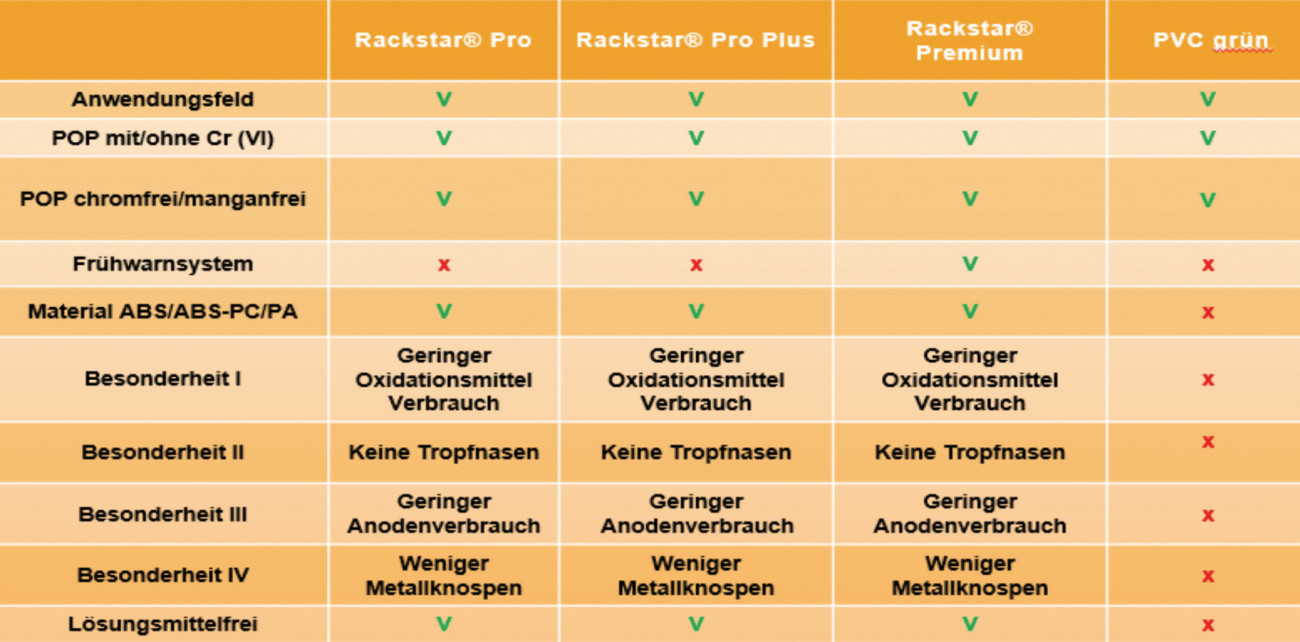

Drip nose bubble metal buds

PVC plastisols are highly viscous mixtures in the manufacturing process that also contain solvents. Due to this high viscosity, care must be taken when insulating that the speed at which the electroplating points are extended is not too high, so that no air pockets or drip bubbles are formed. The surface tension of the plastisol must be set as low as possible. The air inclusions can then be pickled and form metal buds on the rack contacts at an early stage, which impair the service life of the electroplating racks. To avoid this, the patented Rackstar coating process does not use any solvents. Figure 8 shows the fault patterns, Table 4 the properties of the Rackstar variants.

Fig. 7: Contacting left before and right after coating

Fig. 7: Contacting left before and right after coating

Tab. 4: Properties of Rackstar variants

Tab. 4: Properties of Rackstar variants

Summary

Fig. 8: Top left: Drip noses; top right: Rackstar Premium in comparison; bottom left: Metal buds; bottom right: Air entrapment in the Plastisol The innovative Rackstar rack insulation systems meet the current requirements of the EU regulation. Specialist companies and coaters still have the option of coating plastics, but in future with the help of Cr(VI)-free processes that can be easily and simply integrated into existing systems. Various pre-treatment processes are no longer required. The different Rackstar variants offer optimum properties and thus provide a real alternative with PVC plastisols, which also enables the electroplating of 2K blanks. Ultrasonic technology supports the coating of multi-component plastics by blasting off build-up colloids on the PC component and on innovative rack insulation systems in the nucleation process. The use of fluoropolymers extends the service life of the frames. They not only offer high thermal and chemical resistance, but also additional aspects such as the integration of an early warning system. This helps the specialist personnel at the electroplating plant to check the absorption barrier. Thanks to the intact absorption barrier, significantly less manganese is consumed and it stabilizes the Cr(VI)-free pickling process. Metal savings on the rack contact reduce resources, while at the same time less metal sludge is produced in the waste water system and the consumption of waste water chemicals is reduced. This also reduces the burden on the environment. We can be confident that fluoropolymer alloys will become increasingly important for future key technologies.

Fig. 8: Top left: Drip noses; top right: Rackstar Premium in comparison; bottom left: Metal buds; bottom right: Air entrapment in the Plastisol The innovative Rackstar rack insulation systems meet the current requirements of the EU regulation. Specialist companies and coaters still have the option of coating plastics, but in future with the help of Cr(VI)-free processes that can be easily and simply integrated into existing systems. Various pre-treatment processes are no longer required. The different Rackstar variants offer optimum properties and thus provide a real alternative with PVC plastisols, which also enables the electroplating of 2K blanks. Ultrasonic technology supports the coating of multi-component plastics by blasting off build-up colloids on the PC component and on innovative rack insulation systems in the nucleation process. The use of fluoropolymers extends the service life of the frames. They not only offer high thermal and chemical resistance, but also additional aspects such as the integration of an early warning system. This helps the specialist personnel at the electroplating plant to check the absorption barrier. Thanks to the intact absorption barrier, significantly less manganese is consumed and it stabilizes the Cr(VI)-free pickling process. Metal savings on the rack contact reduce resources, while at the same time less metal sludge is produced in the waste water system and the consumption of waste water chemicals is reduced. This also reduces the burden on the environment. We can be confident that fluoropolymer alloys will become increasingly important for future key technologies.