3 Investigations and results for online concentration monitoring and control of HNO3-HF stainless steel pickling plants

3.1 Characterization of the working ranges of mixed acid stainless steel pickling plants and definition of the requirements for the measurement technology

3.1.1 Characterization of the selected stainless steel pickling lines

In order to characterize the typical working areas of HNO3-HF mixed acid stainless steel pickling plants (pickling tanks, acid circuit systems, regenerate stack tanks), analyses of operational samples were carried out in the BFI laboratory and process data provided by the pickling plant operators (typical concentration and temperature data, setpoint ranges) were evaluated. At the BFI, the concentrations of free HF, free HNO3 and total metals were determined using wet chemical titration on a Metrohm analysis system. The proportion of the main metal salts (predominantly Fe, Cr and Ni) in the total metal content was determined using X-ray fluorescence analysis (XRF). Investigations were also carried out to determine typical solid concentrations (gravimetric method). An evaluation of the data obtained is summarized in Table 1.

While laboratory measurements using the advanced process refractometer technology (flange-mounted version, section 3.2) showed sufficient radiolucency values in the operational samples from the strip pickling lines examined, these were usually too low in the samples from the dip tanks of the wire pickling line to allow a plausible refractive index determination due to the typically high particle load concentrations. For the use of the BFI online measurement technology on the wire pickling line, a sample stream pre-treatment using suitable filtration technology (reduction of the solids concentration < approx. 9 g/L for refractometer use) was required in this case.

3.1.2 Definition of the requirements for the measurement technology

The following basic requirements are placed on the online concentration measurement technology for mixed acid pickling solutions that can be used for operational purposes

- Continuous and simultaneous determination of the concentrations of free HF, free HNO3 and total metals in g/L

- Concentration and temperature ranges: Values approx. according to data in Table 1

- Applicable for solid concentrations in the acid solution up to approx. 9 g/L

- Measurement uncertainty: < ± 5 g/L for free HF and total metals, < ± 8 g/L for free HNO3

- Modular, robust and low-maintenance measuring technology (e.g. automated system flushing)

- Display of concentration data and system status information on the device and interfaces for data transfer to the pickling line control system

- Switching to different measuring programs (manually on the device and via external control signal, e.g. from the pickling line control system) and

- Personnel costs for the supervision of the measurement technology, material consumption (chemicals) and wear and tear of the measurement technology should be significantly lower compared to existing analysis methods (e.g. manual wet chemical titration).

|

Wire immersion pickling |

Strip pickling |

Mixed acid regenerate |

|

| HF (free) in g/L | approx. 25-55 | approx. 3-60 | approx. 25-75 |

|

HNO3 (free) in g/L |

approx. 70-200 | approx. 70-200 | approx. 90-200 |

| Total metal (sum Fe, Cr, Ni) in g/L | approx. 10-70 | approx. 10-60 | approx. 1-8 |

|

Filterable substances (pickling sludge, particle size > 8 µm) in g/L |

Ø approx. 10-280 | Ø approx. 2-6 | Ø approx. < 1 |

| T in °C | approx. 20-43 | approx. 20-60 | approx. 20-45 |

3.2 Design and optimization of the prototype online concentration measurement technology

3.2.1 Optimization of the sensor-tube measuring section

Fig. 3: Sensor measuring section with separate refractometer rinsing connection In initial operational investigations with test measuring systems on mixed acid stainless steel strip pickling [4], limitations were identified that required further optimization of the online measuring technology for robust industrial applicability.

Fig. 3: Sensor measuring section with separate refractometer rinsing connection In initial operational investigations with test measuring systems on mixed acid stainless steel strip pickling [4], limitations were identified that required further optimization of the online measuring technology for robust industrial applicability.

A fundamental improvement in the long-term usability of the measurement technology and a reduction in maintenance costs was achieved by replacing the highly corrosion-resistant process refractometer with flow measuring cell [3, 4] (Fig. 1, left, see issue 7/2021, p. 872) with a newly developed flange-mounted version [5] (Fig. 1, right, see issue 7/2021, p. 872). Through further application-related device modifications, the usability for operational mixed acid pickling solutions could be increased from approx. 2-3 g/L to approx. 9 g/L solids content. In contrast to the flow cell version (flow opening << 8 mm), the risk of blocking with sediments (scale particles, crystalline precipitates) can be significantly reduced by installing the flange version (with larger measuring gap opening) in the DN80 pipe.

The availability of a larger process refractometer (here type PIOX R400, Flexim GmbH, Germany) made it possible to optimize the sensor-measuring section pipe structure. The refractometer could now be integrated into the DN80 PVDF measuring pipe section together with the other two sensors (Fig. 2, see issue 7/2021, p. 873), eliminating the need for a separate pipe bypass for the flow cell version. The flange connections at both ends of the measuring tube allow a more flexible connection to the acid circulation system with corresponding reduction segments (> DN32 recommended). A flange sensor type with ETFE protective coating (LiquiSonic pipe sensor V10 DN80, SensoTech GmbH, Germany) was used for continuous measurement of the ultrasonic velocity. Compared to the previously used ECTFE coating (approx. 0.8-1 mm coating thickness), the special ETFE polymer material and the higher coating thickness of approx. 2 mm should enable longer sensor service lives in mixed acid solutions. The higher coating thickness requires the use of an additional external temperature sensor (PTFE protective coating) to ensure rapid acquisition of the temperature signal for the concentration calculation model. The electrical conductivity is measured using a PFA-coated ring probe (type ISC40-TG/TFN, Yokogawa).

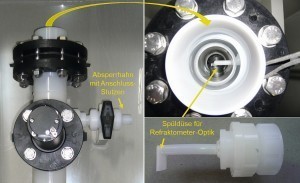

In order to reduce the maintenance effort and to carry out service work (e.g. removal of sensors for validation or repair), appropriate connections were installed at the measuring point for manual or automated flushing of the entire sensor measuring section pipe structure (including sensor surfaces) to remove deposits with water. Furthermore, an improved separate rinsing device (spray nozzle) was integrated, which enables targeted cleaning of the optical components (sapphire window) as required using a water jet via a manually or automatically activated water connection (Fig. 3).

The vertically aligned sensor/measuring section tubular structure (made by KTM GmbH, Montabaur, Germany) is enclosed by a plastic housing (PP material) with a removable transparent front panel to optimize the operating and measuring conditions (Fig. 2). This serves to extend the service life of the measuring technology by protecting it from the often harsh environmental conditions at mixed acid pickling plants (surface contamination from dirt, acid vapors and acid leaks) and to protect the operating personnel from mixed acid contamination in the event of leaks in the measuring system. The openings for the pipe connections and sensor cables can be variably attached to the pickling systems during installation on site.

3.2.2 Optimization of measurement technology control cabinet and model controller

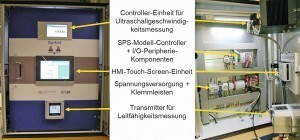

Fig. 4: Prototype measurement technology control cabinet with model controller and peripherals In comparison to initial test and prototype measurement technology developments [4, 5], the model controller (processing of physical online measurement data and concentration data calculation) and peripheral components (e.g. data interface connections for sensor and measurement transmitter connection as well as data communication with the pickling line control system, touch screen display) were implemented using standard PLC modules (Fig. 4). This makes it easier to carry out future system modifications and repair work by replacing individual components. In order to improve the configuration, operation and error handling of the measurement technology with regard to safer and more stable functionality, the measurement data processing and display as well as the system configuration have been programmed with PLC software. The monitoring of the physical measurement parameters has also been optimized, e.g. through application-related measurement signal range limitations and signal error filters. As an alternative to 4-20 mA analog signal data output connections (calculated concentrations, acid temperature) and digital I/O interface connections (information on system function and error status, model data set selection), convenient bidirectional data exchange via a standard Ethernet TCP/IP interface is now also possible. The control cabinet dimensions (height x width x depth) are currently 1.0 x 0.8 x 0.3 m.

Fig. 4: Prototype measurement technology control cabinet with model controller and peripherals In comparison to initial test and prototype measurement technology developments [4, 5], the model controller (processing of physical online measurement data and concentration data calculation) and peripheral components (e.g. data interface connections for sensor and measurement transmitter connection as well as data communication with the pickling line control system, touch screen display) were implemented using standard PLC modules (Fig. 4). This makes it easier to carry out future system modifications and repair work by replacing individual components. In order to improve the configuration, operation and error handling of the measurement technology with regard to safer and more stable functionality, the measurement data processing and display as well as the system configuration have been programmed with PLC software. The monitoring of the physical measurement parameters has also been optimized, e.g. through application-related measurement signal range limitations and signal error filters. As an alternative to 4-20 mA analog signal data output connections (calculated concentrations, acid temperature) and digital I/O interface connections (information on system function and error status, model data set selection), convenient bidirectional data exchange via a standard Ethernet TCP/IP interface is now also possible. The control cabinet dimensions (height x width x depth) are currently 1.0 x 0.8 x 0.3 m.

3.3 Extension and optimization of the concentration calculation model

3.3.1 Investigations into the model extension

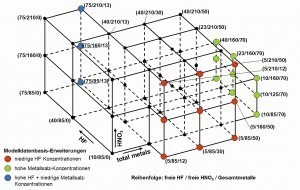

Fig. 5: Schematic 3D representation of the support points of the HNO3-HF total metal model database(free HF, free HNO3, total metals) The mathematical-physical concentration calculation model for HNO3-HF acid mixtures [3, 4] previously developed at the BFI had to be extended for the typical working range (concentration and temperature ranges) of the selected stainless steel pickling plant applications. The focus here was on expanding the model database for the following mixed acid measurement applications:

Fig. 5: Schematic 3D representation of the support points of the HNO3-HF total metal model database(free HF, free HNO3, total metals) The mathematical-physical concentration calculation model for HNO3-HF acid mixtures [3, 4] previously developed at the BFI had to be extended for the typical working range (concentration and temperature ranges) of the selected stainless steel pickling plant applications. The focus here was on expanding the model database for the following mixed acid measurement applications:

- Wire pickling: higher concentrations of total metal salts up to approx. 70 g/L

- Strip pickling for martensitic steel grades: low concentrations of free HF up to approx. 5 g/L and

- Regenerate (from Andritz PYROMARS plant): low concentrations of dissolved metal salts up to approx. 10 g/L (e.g. in the event of plant malfunctions) with high concentrations of free HF (approx. 40-75 g/L) and free HNO3 (approx. 85-210 g/L).

To expand the model database, additional measurements of the physical parameters vUS, λel. and nD between approx. 20 and 65 °C were carried out with synthetic acid solutions of defined concentration combinations in the multi-sensor laboratory system [1]. The physical measurement data and corresponding reference analysis data were integrated into the model database for the application-related expansion of the calculation models. With more than 48 support points, this comprises a range with higher acid and lower total metal concentrations (fresh pickling acid, regenerate) as well as a range with lower acid and higher total metal concentrations (spent pickling acid), see schematic model sketch in Figure 5.

3.3.2 Optimization of the concentration calculation model

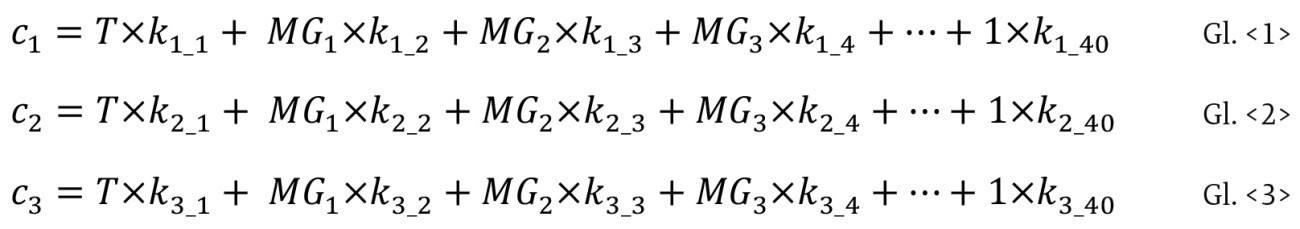

The focus of these investigations was on the further development of the concentration calculation models for carrying out operational measurement technology demonstrations in wire pickling and strip pickling for ferritic and martensitic steel grades including regenerate stack tanks and on further optimization with regard to measurement accuracy. Using the model base points, calculation models were developed in MatLab® for the concentrations of free HF, free HNO3 and total metals (Fe, Cr, Ni). These are based on multi-parameter polynomial functions according to equation <1> to <3>. The structure of the polynomial functions is identical for all three concentrations. The coefficients (k_x_y, x = 1-3, y = 1-40) are determined using multivariate polynomial regression analysis [26] based on the physical measured variables T, vUS, λel. and nD as well as the assigned reference concentrations c1, c2 and c3.

The polynomial functions for calculating the three relevant mixed acid concentrations are stored in the model con troller of the online measurement technology. The coefficient matrix is transferred to the controller as a file as part of application-related model data sets. In addition to the laboratory model database, a MatLab® program has been developed to generate additional support points using interpolation and extrapolation algorithms. The higher data density serves to improve model training and validation studies. By making adjustments to the multivariate polynomial regression functions, e.g. by adding and modifying additional terms of parameter combinations, the accuracy of the concentration calculation models in relation to the model database could be further optimized.

There are certain limitations with regard to the applicability of this model type for the mathematical representation of the complete data matrix. Particularly with regard to the concentration variable free HF, the deviations increase with decreasing temperature < approx. 40 °C. An application-related range limitation of the model data matrix is currently the most suitable option for increasing model accuracy. Furthermore, the suitability of alternative regression model types, e.g. random forest regression or K-nearest neighbor regression [26], was investigated for this application. The results show that the training and validation effort of such models is significantly higher compared to the multivariate polynomial regression model and the performance with regard to unknown application data is lower. Further investigations must be carried out for a future metrological implementation.

Since the synthetic model mixed acid solutions used differ in their matrix from the operational acid solutions (e.g. particle load, metal salt variations) and there are also system-related differences between the BFI laboratory system and operational online measurement technology, calibration to the application-related conditions using sample reference analysis is required. The differences between the model and the reference value determined for the three concentration parameters can either be adjusted by applying calibration functions or referenced operational measurement data can be used directly when training the model. For this purpose, intensive investigations were carried out as part of the operational measurement technology demonstrations. In addition to simple linear calibration functions, more complex polynomial functions can also be activated in the model controller, which enable improved correction for different model areas.

3.4 Investigations into the optimization of concentration monitoring and control in stainless steel mixed acid pickling plants

3.4.1 Stainless steel strip pickling line and acid regeneration plant

The aim of the investigations was to test and optimize the online prototype measurement technology under operational conditions on an Outokumpu strip pickling line of Andritz Metals AG, Austria for martensitic and ferritic steel grades and to optimize the concentration monitoring and control.

Continuous concentration monitoring of mixed acid pickling solutions

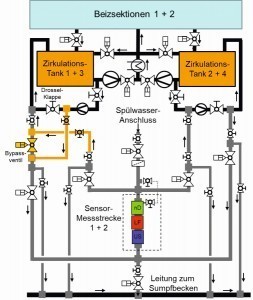

Fig. 6: Schematic representation of the online measurement technology integration in the acid circuit of the strip pickling line Two prototype online measurement systems were installed on the pickling line and one system on a regenerate stack tank. Among other things, the pickling line consists of two mixed acid pickling sections, whereby each pickling tank can be optionally supplied by two acid circulation tanks (Fig. 6). This enables fast and flexible pickling program switching between the process conditions for ferritic and martensitic steel grades. An online measuring system was installed for each pickling section (Fig. 7, left), which for the first time is switched over to the respective active acid circulation system via an automatically controlled valve circuit. Due to the simpler implementation combined with low costs, the circuit connection of the sensor pipe measuring section was made in a bypass configuration to the acid tank circulation pump (Fig. 6, tanks 2 and 4, right). This configuration proved to be disadvantageous in the course of the tests. The insufficient volume flow of < 3m3/h repeatedly led to heavy pickling sludge deposits on the sensors, which resulted in major malfunctions of the sensor functions and greater maintenance requirements. To eliminate these unfavorable measuring and operating conditions, a test modification of the measuring technology circuit connection was carried out on two tank systems. Here, the supply and return lines to the measurement technology were first branched off from the circuit in the pressure line after the pump (Fig. 6, tanks 1 and 3, left). A volume flow of approx. 10m3/h in the bypass circuit could be set manually via a throttle valve (approx. 50 % closed). In this configuration, the automatic switchover to the other tank circuit requires an additional automatic valve.

Fig. 6: Schematic representation of the online measurement technology integration in the acid circuit of the strip pickling line Two prototype online measurement systems were installed on the pickling line and one system on a regenerate stack tank. Among other things, the pickling line consists of two mixed acid pickling sections, whereby each pickling tank can be optionally supplied by two acid circulation tanks (Fig. 6). This enables fast and flexible pickling program switching between the process conditions for ferritic and martensitic steel grades. An online measuring system was installed for each pickling section (Fig. 7, left), which for the first time is switched over to the respective active acid circulation system via an automatically controlled valve circuit. Due to the simpler implementation combined with low costs, the circuit connection of the sensor pipe measuring section was made in a bypass configuration to the acid tank circulation pump (Fig. 6, tanks 2 and 4, right). This configuration proved to be disadvantageous in the course of the tests. The insufficient volume flow of < 3m3/h repeatedly led to heavy pickling sludge deposits on the sensors, which resulted in major malfunctions of the sensor functions and greater maintenance requirements. To eliminate these unfavorable measuring and operating conditions, a test modification of the measuring technology circuit connection was carried out on two tank systems. Here, the supply and return lines to the measurement technology were first branched off from the circuit in the pressure line after the pump (Fig. 6, tanks 1 and 3, left). A volume flow of approx. 10m3/h in the bypass circuit could be set manually via a throttle valve (approx. 50 % closed). In this configuration, the automatic switchover to the other tank circuit requires an additional automatic valve.

In addition to the automatic switchover between two acid circuits, a valve circuit was implemented to reduce the maintenance and servicing effort, which enables manual or automated flushing of the sensor measuring section triggered by the system control. The automated variant takes into account both triggering over a definable time interval (e.g. every 24 h) and limit value monitoring of the process refractometer signal amplitude, which is an indicator of the degree of deposit formation on the optical components of the sensor, among other things. A rinsing nozzle has also been integrated for targeted cleaning of the sapphire windows and the measuring gap of the process refractometer. This is supplied via a variable partial volume flow of the measuring section rinsing connection (Fig. 7, center).

Data communication between the three online measuring systems and the pickling line control system was implemented using TCP/IP Ethernet interfaces with technical support from the plant manufacturer Andritz AG. The concentration data and status information from the three systems are processed and recorded in the PLC system and displayed on the HMI in the line control station (Fig. 7, right). After the mechanical installation and electrical connection, tests were carried out to optimize the measuring systems for the operational measuring and operating conditions. This included the application-related calibration of the concentration calculation models using reference analysis, model, software and hardware optimizations to improve measurement accuracy and long-term functionality as well as functional tests in circuit switching and cleaning operation. Under optimum measurement conditions, the deviations between the values of the BFI reference analysis and the model-based online measurement are in the range of approx. ± 5 g/L for the concentrations of free HF and total metals and in the range of approx. ± 8 g/L for the concentration of free HNO3.

Continuous concentration control on mixed acid pickling lines

Fig. 7: Prototype of the online measurement technology on the mixed acid strip pickling line and measurement technology data display in the control station (right) To adjust the mixed acid concentrations, the plant manufacturer Andritz uses a combination of a recipe-based automated pre-dosing function for each coil and a correction dosing function based on the target/actual value deviations determined using offline/atline analysis. Depending on the steel grades to be pickled, the pickling process control and analysis frequency (approx. every 8 h), this control concept can result in larger target/actual value deviations.

Fig. 7: Prototype of the online measurement technology on the mixed acid strip pickling line and measurement technology data display in the control station (right) To adjust the mixed acid concentrations, the plant manufacturer Andritz uses a combination of a recipe-based automated pre-dosing function for each coil and a correction dosing function based on the target/actual value deviations determined using offline/atline analysis. Depending on the steel grades to be pickled, the pickling process control and analysis frequency (approx. every 8 h), this control concept can result in larger target/actual value deviations.

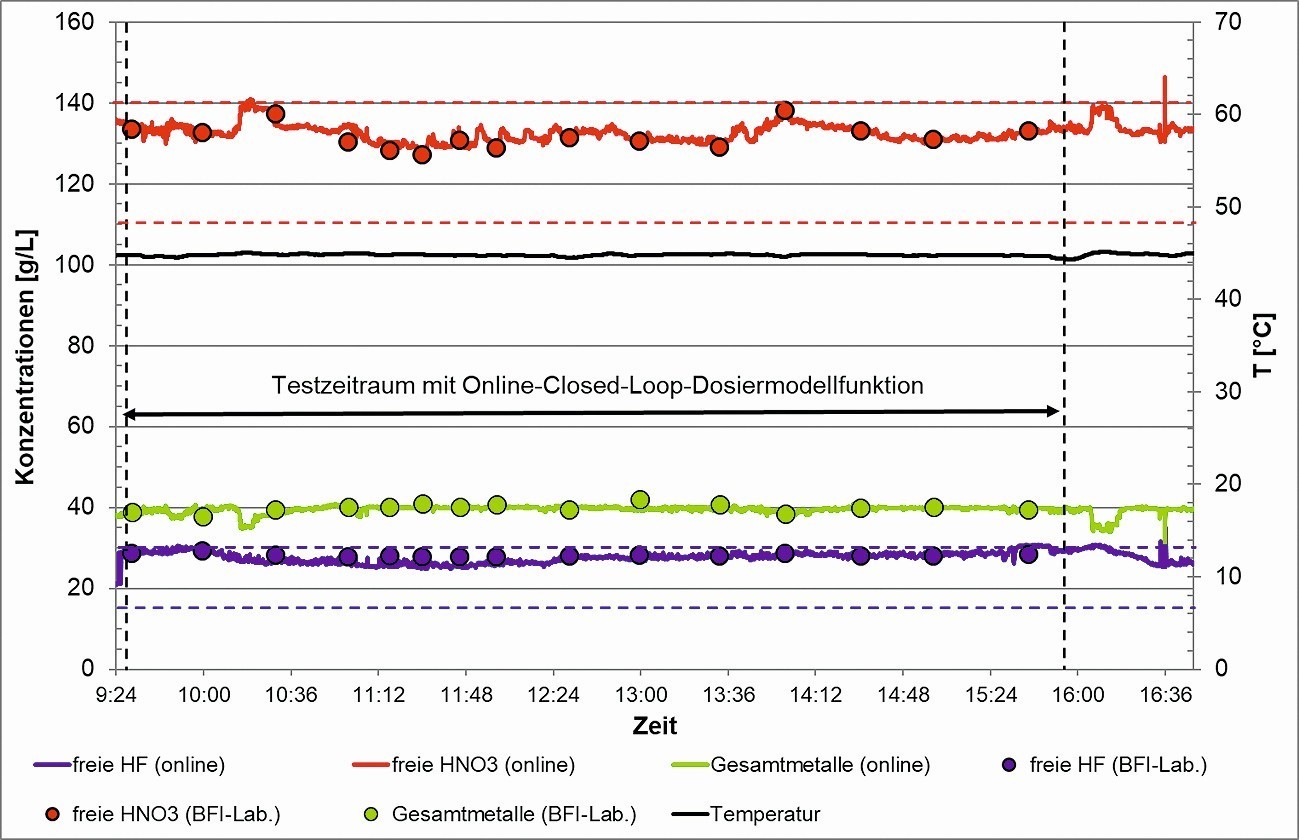

To stabilize the pickling bath concentrations in the defined target value ranges, a closed-loop control model based on the online analysis data was developed with the support of Andritz and integrated into the process control technology. The advanced control model is installed in addition to the Andritz standard model and can be activated manually. When active, status information and the online concentration data are checked at defined intervals. If the system status is OK and the plausibility of the concentration data is signaled by the measurement technology, Andritz's own model algorithm calculates the volumes of fresh HF and HNO3 as well as water and regenerate to be dosed based on the target/actual value deviations and other system and process parameters such as tank circulation volumes, fill levels and acid concentrations. Tests with the advanced concentration control model have shown that intervals of 10 minutes with smaller, quickly homogenizable dosing volumes enable good stabilization of the pickling acid concentrations. Figure 8 shows an example of a curve of the pickling acid concentration data during the activated closed-loop control model. The advanced control model enables good stabilization of the acid concentrations. There is good agreement between online analysis data and the BFI reference analysis values. To save fresh HF and HNO3, the dosing of mixed acid regenerate is preferred. If there are faults in the online measuring systems, the plant process technology switches to the Andritz standard dosing model after a defined period of time, or back to the closed-loop dosing model once the fault has been eliminated.

Fig. 8: Concentration curve in the pickling acid circulation system during activated closed-loop concentration control model

Fig. 8: Concentration curve in the pickling acid circulation system during activated closed-loop concentration control model

- is continued -

List of symbols and abbreviations

|

Symbol |

Symbol Description |

Unit |

|

Cx |

Acid or metal salt concentration |

g/L |

|

k_x_y |

Polynomial coefficients |

g/L |

|

MGx |

Measured variable (vUS, λel, nD) |

various |

|

nD |

Refractive index |

- |

|

T |

temperature |

°C |

|

vUS |

Ultrasonic velocity |

m/s |

|

λel. |

Electrical conductivity |

mS/cm |

|

Abbreviation |

Abbreviation Description |

|

CPN |

Causal-Probabilistic-Networks |

|

Cx |

Concentration |

|

Cr |

chromium |

|

E-CTFE |

Ethylene-chlorotrifluoroethylene |

|

EDS |

Energy Dispersive Spectroscopy |

|

FFKM / FKM |

Perfluoro rubber / Fluoro rubber |

|

Fe |

iron |

|

FEG-SEM |

Field Emission Gun-Scanning Electron Microscopy |

|

GUI |

Graphical User Interface |

|

H+ |

Hydrogen ions |

|

H2SO4 |

Sulphuric acid |

|

HCl |

Hydrochloric acid |

|

HF HYDROFLUORIC ACID |

Hydrofluoric acid |

|

HNO3 |

Nitric acid |

|

IRS |

Infrared spectroscopy |

|

kx_y |

Polynomial coefficients |

|

Ni |

nickel |

|

PFA |

Perfluoroalkoxylalkane |

|

PTFE |

Polytetrafluoroethylene |

|

PVDF |

Polyvinylidene fluoride |

|

XRF |

X-ray fluorescence analysis |

|

SOM-(NG) |

Self-Organizing-Map-(Neural Gas) |

Literature

[1] Kessler, R.W.: Process analytics - strategies and case studies from industrial practice, Wiley-VHC Verlag (2012)

[2] Industry 4.0: http://www.bfi.de/de/themen/industrie-4-0-und-messtechnik/

[3] Werner, M.; Wolters, R.; Titze, K.; Kozariszczuk, M.: New measuring method for continuous concentration measurement in HNO3-HF mixed acid etchings, Jahrbuch Oberflächentechnik Volume 69, 2013, 304-322

[4] EU-RFCS project Flexible production by multi sensor process control of pickling lines (FLEXPROMUS, RFSR-CT-2010-00017, 7/2010-12/2013)

[5] Werner, M.; Wolters, R.; Kozariszczuk, M.; Hoheisel, G.; Ludwig, J.; Bange, S.: Industrietaugliche Online-Messtechnik zur Konzentrationsüberwachung von HCl-Fe(II)-Fe(III)-Beizbädern, Jahrbuch Oberflächentechnik Volume 72, 2016, 231-254 and Galvanotechnik, Volume 108, 2017, Issues 9 and 10

[6] Rituper, R.: Pickling of metals, Eugen G. Leuze Verlag, Bad Saulgau (1993)

[7] Giordani, P.; Rigamonti, M.; Gasparetto, V.: Stainless steel pickling processes with non-toxic Cleanox (Registered trademark) solutions, Wire Journal International, 39 (2006) 8, 62-66

[8] EU-RFCS project Optimization of the mixed-acid online monitoring and control in stainless steel pickling plants (MACO Pilot, Grant Agreement Nr. 709694, 7/2016-12/2019

[9] Kang, G.; Lee, K.; Park, H.; Lee, J.; Jung, Y.; Kim, K.; Son, B.: Quantitative analysis of mixed hydrofluoric and nitric acids using Raman spectroscopy with partial least squares regression, Talanta, Volume 81, Issues 4-5, June 15, 2010, 1413-1417

[10] Dinger, F.: Indirekt zum Ziel - Inline process analysis with integral measurement methods, Chemietechnik 3 (2006), 22-30

[11] SIROLLCIS FAPLAC technology package for SIROLLCIS pickling lines, company publication, Siemens VAI, Metals Technologies GmbH & Co, Linz, Austria

[12] Monitoring of pickling baths, company publication Anton Paar GmbH (Graz, Austria, www.anton-paar.com)

[13] German patent 10 2004 023 734: Method and device for determining the concentration of at least one metal salt and at least one acid of a pickling acid containing at least one metal salt

[14] Wolters, R.; Schmidt, B.: Improvement of the pickling process by continuous and simple online monitoring of the pickling bath quality, final report on the AiF research project FKZ 14062 N, August 2007, BFI report no. 4.48.129

[15] EU-RFCS project Sensor-based online control of pickling lines (SensorControl, EUR 23872 EN, 07/2004-12/2007)

[16] EU-RFCS project Implementation of sensor based online control of pickling lines (SensorControlPilot, EUR 25320-EN, 07/2007-06/2010)

[17] Process analytics in steel and rolling mills, SensoTech GmbH, stahl und eisen 132 (2012) 5, 94

[18] Park, H.K.; Lee, J.H.; Noh, I.-H.: Development of a concentration measurement system for pickling line control, Journal of Institute of Control, Robotics and Systems, Volume 19, (10) 2013, 891-895

[19] Radiometric measuring systems / Acid management in pickling lines, Company publications, Berthold Technologies GmbH & Co, KG, Bad Wildbad

[20] Critchley, S.; Voges, K.; Mueth, A.; Lehane, B.: Eco pickled surface: an enviromentally advantageous alternative to conventional acid pickling, AISTech 2007, Iron and Steel Techn. Conference, AIST, Proceedings, Vol. 2, Indianapolis, US, May (2007) 7-10, 1-18

[21] Rögener, F.; Buchloh, D.; Schmidt, B.: Sustainable process control in the pickling of stainless steels, Galvanotechnik 98 (2007) 12, 2921-2928

[22] Marx, Th.; Quirmbach, O.; Rituper, R.; Wohnig, I.: New process increases pickling speed and reduces length of pickling lines, MPT International, 3/2015, 132-135

[23] New developments for efficient pickling, SMS group, stahl und eisen 135 (2015) No. 6/7, 135

[24] Process refractometer for concentration measurement in chemically aggressive media, K-Patents AG (Vantaa, Finland, www.buehler-technologies.com)

[25] Process analysis by inline refractometry, company publication FLEXIM GmbH (Berlin, Germany, www.flexim.com/de)

[26] Géron, A.: Practical introduction - Machine Learning with Scikit-Learn & TensorFlow, O'REILLY-Verlag (2017)

[27] https://www.dantecdynamics.com/solutions-applications/solutions/laser-shearography-ndt/

[28] Machón-González, I.; López-García, H.; Bocos-Barranco, I.: Dynamics identification and control of nonlinear MIMO coupled plant using supervised neural gas and comparison with recurrent neural controller, Neural Computing and Applications, 2019, available in: <https://doi.org/10.1007/s00521-019-04195-9> full-text view-only version https://rdcu.be/bEdgbUniOvi 1

[29] Machón-González, I.; López-García, H.: Feedforward Nonlinear Control using Neural Gas Network, Complexity, John Wiley & Sons - Hindawi Publishing Corporation, 2017, available in: https://doi.org/10.1155/2017/3125073

[30] Eduardo-Espitia, H.; Machón-González, I.; López-García, H.; Díaz-González, G.: Proposal of an Adaptive Neurofuzzy System to Control Flow Power in Distributed Generation Systems, Complexity, 2019, ISSN 1076-2787, available in: https://doi.org/10.1155/2019/1610898