3.4.2 Stainless steel wire pickling line with sample stream pre-filtration

Similar to the strip pickling line, the wire pickling line has an automated pre-dosing function for the mixed acid pickling tanks, which is used to compensate for process-related acid consumption. In addition, the pickling tank concentrations are checked at intervals of approx. 8 hours using offline analysis and, if necessary, the volumes of fresh acids and water determined by a calculation algorithm are added. After sample preparation, each analysis in the Metrohm titration system takes approx. 25 minutes, so that the result for the first basin is available after approx. 30 minutes and for the last basin after approx. 2.5 hours. Depending on the pickling process, the tank concentrations may have changed in the meantime until a corrective dosage can be carried out on the basis of the new analysis data. To improve concentration monitoring and control, it is necessary to increase the frequency of analysis.

The aim of these investigations was therefore to test and optimize the online prototype measurement technology under operational conditions for various steel grades and to improve concentration monitoring and control based on this. Due to the high concentration of solids (>> 10 g/L) typical of the plant and process in the immersion pickling tanks, a suitable filtration technology had to be installed upstream of the online measurement technology to ensure the measurement function of the transmitted light process refractometer in the sample stream in particular.

Sample stream filtration and online concentration monitoring

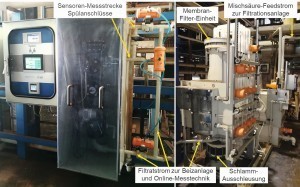

Fig. 10: Online measurement technology installed on DEW wire pickling plant (left) and upstream filtration system (right)The pickling plant consists of five mixed acid immersion pickling tanks in which approx. 10m3 of acid volume is circulated via circulation pump systems with a volume flow of approx. 20-30m3/h (see Fig. 9). The integrated heat exchangers are used to discharge energy generated by the pickling process (usual tank temperatures < 40 °C). The selected membrane-based mixed acid filtration system with feed tank from Scanacon AB (Sweden) was integrated into the circulation systems via feed and return lines in such a way that manual or automated switching between the five pickling tanks is possible. The feed volume flow is between approx. 2-4m3/h, depending on the solids concentration. The prototype online measuring system was connected to the filtrate sample flow via a controllable bypass circuit. This allows the sensor measuring section to be disconnected for cleaning purposes, e.g. by means of manually activated water rinsing of the refractometer optics. As soon as the particle layer on the filter cartridges with a membrane mesh size of approx. 0.8 µm has grown too much and the filtrate flow falls below a definable limit value (approx. 30-35 L/min.), the filtration process is stopped and the filter cartridges are cleaned in counterflow with water via a backwash process. The sludge falls through a bottom flap into a collecting tank with agitator for further processing. In contrast to the belt pickling plant mentioned above, the used acid is not regenerated but neutralized together with the rinsing water and pickling sludge produced.

Fig. 10: Online measurement technology installed on DEW wire pickling plant (left) and upstream filtration system (right)The pickling plant consists of five mixed acid immersion pickling tanks in which approx. 10m3 of acid volume is circulated via circulation pump systems with a volume flow of approx. 20-30m3/h (see Fig. 9). The integrated heat exchangers are used to discharge energy generated by the pickling process (usual tank temperatures < 40 °C). The selected membrane-based mixed acid filtration system with feed tank from Scanacon AB (Sweden) was integrated into the circulation systems via feed and return lines in such a way that manual or automated switching between the five pickling tanks is possible. The feed volume flow is between approx. 2-4m3/h, depending on the solids concentration. The prototype online measuring system was connected to the filtrate sample flow via a controllable bypass circuit. This allows the sensor measuring section to be disconnected for cleaning purposes, e.g. by means of manually activated water rinsing of the refractometer optics. As soon as the particle layer on the filter cartridges with a membrane mesh size of approx. 0.8 µm has grown too much and the filtrate flow falls below a definable limit value (approx. 30-35 L/min.), the filtration process is stopped and the filter cartridges are cleaned in counterflow with water via a backwash process. The sludge falls through a bottom flap into a collecting tank with agitator for further processing. In contrast to the belt pickling plant mentioned above, the used acid is not regenerated but neutralized together with the rinsing water and pickling sludge produced.

Figure 10 shows the filtration and measuring technology installations that have been implemented. Data is exchanged between the two systems and the pickling plant control system via the Profibus interface of the Scanacon system or the standard TCP/IP interface of the online measuring technology. In addition to the relevant system parameters, status information, valve switching states, input fields and operating elements, the values of the online analysis technology are displayed on the control station HMI in parallel to the results of the offline concentration analysis. After commissioning the filtration system, various tests were first carried out to determine suitable operating points and tank switching times.

This was followed by the calibration of the online measurement technology to the concentration and temperature ranges of the five pickling tanks using BFI reference analysis. In comparison to the described application on the strip pickling line, the challenge here was that after switching a pickling tank to the filtration system, a certain amount of time is required until the acid solution present in the receiver tank, filter system and sensor measuring tube section has been sufficiently exchanged for the new solution. Studies have shown that time intervals of approx. 20-25 minutes after the tank changeover process are sufficient for the exchange of the acid solution and temperature stabilization. As the filtration process can result in a greater accumulation of gas bubbles in the filtrate flow, the measuring technology bypass is disconnected from the filtrate flow for approx. 4 minutes to stabilize the measuring conditions before the concentration values are taken over by the pickling plant control system. Based on the results and empirical values, intervals of 30 minutes were finally defined for the automated time-controlled tank switchover. In the case of filter cartridge cleaning, these intervals are extended by approx. 5 minutes. Compared to offline analysis, this results in a reduction of the tank analysis intervals to approx. 2.5 hours.

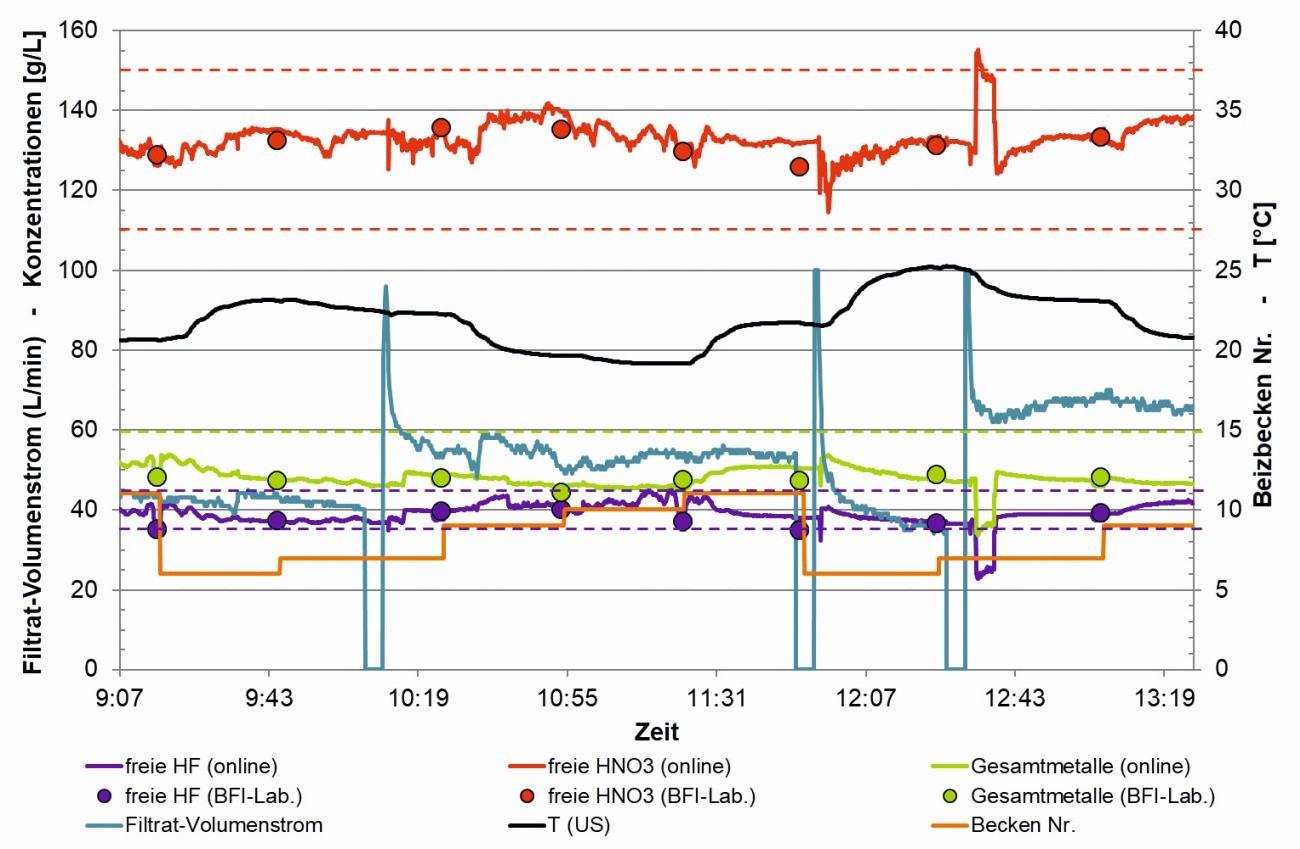

Under optimum measurement conditions, the deviations between the values of the BFI reference analysis and the model-based online measurement are predominantly in the range of approx. ± 5 g/L for the concentrations of free HF and total metals and in the range of approx. ± 8 g/L for the concentration of free HNO3. The investigations have shown that the increased analysis frequency enables improved corrective dosing in the five pickling tanks. Figure 11 shows an example of the concentration curves for a period in which a time-controlled switchover to the five mixed acid tanks was carried out. The trend values of the sample flow temperature and the filtrate flow are also shown. The concentration values relevant to the respective switchover points show good agreement with the BFI reference analysis values.

Fig. 11: Concentration and temperature curve of the online measurement technology sample flow at the wire pickling plant during the automated pickling tank switchover

Fig. 11: Concentration and temperature curve of the online measurement technology sample flow at the wire pickling plant during the automated pickling tank switchover

3.4.3 Investigations into sensor corrosion and service life

A very important criterion for the industrial use of online measurement technology in mixed acid is the service life of the online sensors used under the extreme operating conditions with high HF and HNO3 acid concentrations at temperatures of up to approx. 60 °C. Due to the high procurement costs of up to approx. 25,000 € net per set, a minimum of five years is aimed for here. There is little long-term experience with regard to the suitability of the sensor materials that come into contact with the mixed acid solutions. Further contents of the pilot project were therefore investigations of the sensor corrosion behaviour under defined conditions in the laboratory as well as optimization possibilities that can be derived from this during use.

For the laboratory tests at the project partner RISE, test specimens of various sensor material sets with PFA, ETFE and E-CTFE powder-coated stainless steel rods with a layer thickness of approx. 1 and 2 mm, PTFE-carbon compound pieces, sapphire windows and sealing rings were used. These were stored for up to 2 years in highly concentrated mixed acid solutions with approx. 8 % w/w HF and 20 % w/w HNO3 at elevated temperatures of approx. 60 and 80 °C to accelerate ageing. To determine the acid diffusion over time and the resulting corrosion effects, the surfaces and layers of the specimen sets were examined at intervals of approx. 6 months using non-invasive measurement methods, e.g. LASER shearography [27] and invasive methods, e.g. FEG SEM, EDS and IRS. With regard to the ultrasonic sensor, the type of protective coating used appears to be of less importance than other coating factors. Compared to the E-CTFE and ETFE coated rods, the PFA coated specimens showed a greater number of delamination effects. This was attributed to the differences in the coating process rather than the suitability of the PFA material. As there were no clear differences between the corrosion resistance of the E-CTFE and ETFE coating materials and their coating thickness, it does not currently make sense to use the more expensive sensor flange ring design with the thicker ETFE coating for operational mixed acid measurement technology. The conclusion that the type of coating material and coating thickness are less important for the service life than the quality of the coating process is supported by the results from the investigations of the sensors used in operation.

With regard to the construction materials of the process refractometer, the FFKM O-rings tested for the sapphire window and housing seal showed good resistance but long-term weaknesses in compression set stability. Alternatives here would be FKM O-ring types with more stable sealing properties, provided they can be used for mixed acid solutions. A certain change in the transmission properties was observed in the sapphire window samples. However, no experience has yet been gained as to the extent to which this affects the service life of the sensors.

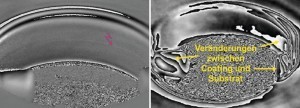

Fig. 12: Image comparison of US sensor flange rings with LASER shearography method (left - original unused, right - after approx. 2.3 years in mixed acid use) In addition to the laboratory tests, periodic checks of the corrosion behavior of the online sensors used operationally on the four measurement applications were carried out at intervals of approx. 6 months during the project. The visual surface inspection of the removed sensors showed no significant changes indicating corrosion damage after periods of use of up to approx. 26 months. The ETFE-coated ultrasonic velocity sensors (see Fig. 2, bottom left) were also examined using the non-invasive LASER shear graphy measurement method [27]. The new sensors were used as a reference in each case. Over the operational period of use, changes of varying degrees were observed, which are probably due to corrosion-related delamination effects between the coating and the base material. Figure 12 shows a comparison of LASER shearography images of a new ultrasonic sensor flange ring used in operation for approx. 2 years. The process refractometers were sent to the manufacturer Flexim to check the interior of the optical measuring cells for leaks and corrosion damage. Only one sensor showed slight changes on metallic surfaces, which were presumably caused by acid diffusion on a defective O-ring. The formation of fine bubbles was observed on the PFA surface of the conductivity sensors. According to the results of the periodic validation of the removed sensors, their measuring function was still given. Based on the results of this project and the experience gained from other mixed acid measurement applications, the conductivity sensors and process refractometers have a service life of > 5 years. With regard to the E-CTFE-coated ultrasonic sensors, there is experience of service lives of between approx. 3.2 and 5.5 years and of approx. 4 years for the ETFE variant. As the quality and design of the coating process has a major influence on the service life of these sensors, optimization measures should be discussed and implemented with the companies involved in the manufacturing process in order to ensure service lives of > 5 years in the future.

Fig. 12: Image comparison of US sensor flange rings with LASER shearography method (left - original unused, right - after approx. 2.3 years in mixed acid use) In addition to the laboratory tests, periodic checks of the corrosion behavior of the online sensors used operationally on the four measurement applications were carried out at intervals of approx. 6 months during the project. The visual surface inspection of the removed sensors showed no significant changes indicating corrosion damage after periods of use of up to approx. 26 months. The ETFE-coated ultrasonic velocity sensors (see Fig. 2, bottom left) were also examined using the non-invasive LASER shear graphy measurement method [27]. The new sensors were used as a reference in each case. Over the operational period of use, changes of varying degrees were observed, which are probably due to corrosion-related delamination effects between the coating and the base material. Figure 12 shows a comparison of LASER shearography images of a new ultrasonic sensor flange ring used in operation for approx. 2 years. The process refractometers were sent to the manufacturer Flexim to check the interior of the optical measuring cells for leaks and corrosion damage. Only one sensor showed slight changes on metallic surfaces, which were presumably caused by acid diffusion on a defective O-ring. The formation of fine bubbles was observed on the PFA surface of the conductivity sensors. According to the results of the periodic validation of the removed sensors, their measuring function was still given. Based on the results of this project and the experience gained from other mixed acid measurement applications, the conductivity sensors and process refractometers have a service life of > 5 years. With regard to the E-CTFE-coated ultrasonic sensors, there is experience of service lives of between approx. 3.2 and 5.5 years and of approx. 4 years for the ETFE variant. As the quality and design of the coating process has a major influence on the service life of these sensors, optimization measures should be discussed and implemented with the companies involved in the manufacturing process in order to ensure service lives of > 5 years in the future.

3.5 Development of a pickling program management model for mixed acid wire pickling lines

Compared to mixed acid strip pickling lines, the pickling of stainless steel wire in pickling lines with dip tanks poses special challenges for production planning and pickling process management. The wire coils are guided through the various treatment tanks of the pickling line in the sequence specified at the input end using a crane transport system on hooks. The selection of the individual process tanks and respective treatment times is largely automated via corresponding material-specific control programs. Monitoring and maintaining defined process conditions (concentrations, temperatures) is particularly important in the five mixed acid immersion pickling baths. As described above, the concentrations are monitored and readjusted at intervals of approx. 2.5 h (online analysis) or approx. 8 h (offline analysis). The tank temperatures are continuously monitored and the process-related energy input into the pickling acid is dissipated as required via heat exchangers.

The aim of these investigations was to develop a powerful model-based forecasting tool that enables the predictive development of pickling bath conditions and demand-based changes in pickling process management.

Understanding the sequences of pickling processes and their optimization requires the analysis of parameters that influence these processes. Most of these are already considered and controlled in the pickling operation, e.g. material pre-treatment, mixed acid concentrations and dissolved metal salts, hydraulic conditions and acid exchange during chemical reactions. Other parameters are variables that are already defined before the pickling process, such as steel grades and their alloy composition, material-related heat treatment processes of the wire coils, material-dependent holding times in the pickling tanks and the number of sequentially approached pickling tanks.

The project partner UniOvi used various analysis and modeling methods [16, 28-30] to carry out extensive evaluations of the production, plant and process data provided in conjunction with the established pickling programs for various steel grades. Important findings from this include

- Excessively long holding times can lead to "over-pickling" of the pickling material, causing the surface to be treated unevenly and become porous.

- It is difficult to derive a direct correlation between the pickling result and the acid volume flow or mixing in the tank. High mixing leads to good homogenization of the pickling acid and preservation of the reaction processes. Turbulent flow conditions significantly accelerate the pickling process.

- Higher acid concentrations increase the pickling bath efficiency primarily at lower temperatures. This effect decreases with increasing temperature. The use of higher acid concentrations is limited, among other things, by the higher acid consumption and higher emissions.

- Of all the parameters, however, the pickling bath temperature is a fundamental variable for the pickling process efficiency and the pickling result, as the pickling rate increases with increasing temperature [7]:

- The temperature dynamic effects in the pickling tanks are increased during the pickling process, according to the combination of exothermic chemical reactions and the performance of the cooling system.

- The monitoring and control of the mixed acid temperature is essential for the development of the pickling process:

- Temperatures that are too low reduce the effectiveness of the reactions taking place - temperatures above 25 °C are useful

- Temperatures that are too high can have a negative impact on the pickling result and the pickling process, there is an increased risk of "overpickling" and increased effort within the catalytic exhaust gas cleaning - upper temperature limit < 40-45 °C

Based on the results obtained, the partner UniOvi has developed a model-based management software tool that makes it possible to describe the temperature dynamics in the five mixed acid pickling tanks and predict their further development for several hours in advance. Information from the production and process databases on the material properties, the area to be pickled and the process bath dynamics was used to develop, train and validate the model. Thanks to the introduction of online analysis measurement technology, the target value ranges of the bath concentrations are reliably maintained. A positive effect of this process reliability is that the bath concentrations are only of minor relevance for the temperature prediction model.

Fig. 13: HMI screen on the pickling program management model computer system After extensive testing and optimization in simulation mode, the online version of the model software was installed on separate computer systems at the DEW pickling plant. The information relevant for the forecasting tool, e.g. the sequence of the wire coils to be treated, their material identifiers and planned pickling programs as well as the pickling process data, is transferred via the connection to the process database. There is an HMI display module for continuous monitoring of the process-relevant data from the database system. The current values and the predicted development of the temperatures and heat flow densities of the five pickling tanks based on the planned coil sequence are displayed graphically in separate diagrams (see Fig. 13). Another HMI serves as a supporting management tool for the plant personnel for the wire coil pickling sequence logistics.

Fig. 13: HMI screen on the pickling program management model computer system After extensive testing and optimization in simulation mode, the online version of the model software was installed on separate computer systems at the DEW pickling plant. The information relevant for the forecasting tool, e.g. the sequence of the wire coils to be treated, their material identifiers and planned pickling programs as well as the pickling process data, is transferred via the connection to the process database. There is an HMI display module for continuous monitoring of the process-relevant data from the database system. The current values and the predicted development of the temperatures and heat flow densities of the five pickling tanks based on the planned coil sequence are displayed graphically in separate diagrams (see Fig. 13). Another HMI serves as a supporting management tool for the plant personnel for the wire coil pickling sequence logistics.

The model-based forecast of the tank temperatures enables the plant personnel to better monitor the pickling process and, if necessary, make preventative changes to the pickling process sequence. These could be, for example, changing the sequence of the coils to be pickled at the entrance to the pickling line or using alternative pickling programs to suitably vary the holding times and pickling tank selection. The development and operational use of this model-based forecasting tool is an important step in the optimization of process sequences in mixed acid wire pickling plants.

4 Summary and outlook

As part of the pilot project, the innovative model-based online measurement technology for continuous concentration monitoring of HNO3-HF mixed acid pickling solutions was successfully optimized for industrial use in stainless steel pickling plants. The mathematical-physical calculation model for the three relevant concentration variables free HF, free HNO3 and total metals was supplemented and further improved with regard to the model database for the measurement application envisaged in the project. Furthermore, the measurement technology prototype setup was optimized with a focus on robustness in operational use on mixed acid pickling plants, increasing long-term functional stability and reducing maintenance costs.

The verification of the suitability for use and modifications of the prototype online measuring systems as required were installed on a modern stainless steel strip pickling line and a stainless steel wire pickling line and tested under operational conditions over a period of approx. 2-2.5 years.

A measuring system was installed on each of the two pickling sections of the strip pickling line. For the first time, automated switching between two acid circuits each for ferritic and martensitic steel grades and water rinsing for the sensor measuring section was carried out via the pickling line control system. Investigations with a developed advanced closed-loop control model showed that a significantly better stabilization of the pickling acid concentrations around the target values is possible on the basis of the continuously recorded online concentration data than using the offline analysis values (sampling at approx. 8-hour intervals).

Due to the typically high solids concentration of such pickling solutions, a filtration system had to be installed upstream of the online measuring system operated at the wire pickling plant in order to ensure a stable measuring function of the online sensors for ultrasonic velocity, electrical conductivity and refractive index. By automatically switching to the five immersion pickling tanks, the time intervals for concentration monitoring could be reduced from approx. 8 h (offline analysis) to approx. 2.5 h.

After calibration of the concentration calculation models to the process conditions, the deviations between online measurement and BFI laboratory reference analysis were predominantly in the range of approx. ± 5 g/L for the concentrations of free HF and total metals and approx. ± 8 g/L for free HNO3 concentration.

Various tests with the online sensors used have shown that the target service life of at least five years can be achieved. This requires good manufacturing quality of the corrosion protection coatings as well as regular inspection and maintenance of the sensors.

An innovative pickling program management model was developed for stainless steel wire pickling, which makes an important contribution to optimized and safe pickling process operation. The model-based forecast of tank temperatures over several hours enables plant personnel to better monitor the pickling process and, if necessary, make preventive decisions regarding changes to the pickling program sequence.

Compared to currently available offline/atline analysis systems, the availability of continuously measuring, industrial-grade online analysis technology can lead to significant cost savings in pickling process monitoring through a corresponding reduction in manual sample analyses. In combination with powerful control concepts, online monitoring enables faster adjustment and improved stabilization of mixed acid concentrations to maintain optimal and safe pickling process conditions. The higher monitoring frequency enables a lowering of the acid concentration setpoints and thus a cost saving for the reduced use of fresh acids and the reduction of acid regeneration and disposal costs. According to current estimates, the amortization periods for the procurement, installation and operation of the online measurement technology are between approx. 1 and 4 years, depending on the pickling plant and installation concept.

5 Fields of activity of the project partners

The VDEh-Betriebsforschungsinstitut is a private research institute for applied research with a focus on the steel industry, the metalworking industry and electroplating technology. The Liquid Media Resource Technology department has extensive experience in measurement technology and the treatment of liquid media in these industries. The focus of the liquid media is on cooling water, aqueous emulsions in rolling processes, acids, process and cleaning solutions, steam, waste water and sludge. The objectives are to increase plant productivity, ensure product quality, purify process and waste water as well as recycle and avoid waste water in the production process. In addition to procedures for online concentration monitoring in pickling baths, innovative measurement methods have been developed, e.g. for microbiological activity in cooling water and emulsions, the determination of particle concentration in cooling water and thin sludge as well as polymer concentration in quenching tanks. The BFI focuses on the special needs of steel and metal processing companies. Outokumpu-Nirosta GmbH in Krefeld is part of the Outokumpu Group, a global leader in stainless steel flat products. Outokumpu Nirosta is part of the EMEA division, which comprises all steel coil operations and sales in Europe, the Middle East and Africa in the three business units Avesta, Nirosta and Tornio, with production facilities in Finland, Germany and Sweden. The German division, with rolling mills in Dahlerbrück, Dillenburg and Krefeld, specializes in the production of customized flat products in ferritic, martensitic and austenitic steel grades.

Deutsche Edelstahlwerke Specialty Steel GmbH & Co. KG is part of the Business Unit Deutsche Edelstahlwerke (DEW) of the Schmolz + Bickenbach Group and is the leading producer of stainless steel long products. The product range extends from 0.8 mm diameter drawn wire made from 100% recycled steel scrap to forged products with a diameter of 1100 mm. DEW products are used in both traditional and future-oriented industrial sectors, such as the automotive, aerospace and mechanical engineering industries, as well as in power generation and plant engineering.

Acerinox (ACX) is one of the most competitive companies in the world in the production of stainless steels and nickel alloys. It is the most global company in the industry, with a presence on the five continents, factories on four continents and supplying customers in 81 countries. Since its foundation 50 years ago, ACX has been carrying out a continuous investment program, developing its own technological innovations which, in some cases, represent a real milestone in stainless steel technology. ACX has three fully integrated production plants for flat products in Spain, the USA and South Africa. Acerinox Europa S.A.U. in Los Barrios (Cádiz, Spain) has four pickling lines for flat products. These are operated according to the production process of hot-rolled or cold-rolled steel, three of which are integrated into annealing and pickling lines.

The University of Oviedo (Asturias, Spain) is a non-profit organization and has been included in the Academic Ranking World Universities list of the 500 best universities in the world. As the driving force behind R&D and innovation activities in Asturias, it cooperates with around 500 companies and has made efforts in recent years to raise the standards of technology transfer. The sub-department involved in this project (Ingeniera de Sistemas y Automética) has developed several research prototypes for maintenance, process control, automated control and measurement in collaboration with the steel industry, e.g. [15, 16]. It belongs to the Department of Electrical, Electronic, Computer and Systems Engineering, which is one of the largest departments of the university with the largest volume of funding for research work. In addition, the group specializes in the application of analytical techniques and data visualization to solve specific industrial problems.

RISE - Research Institutes of Sweden - is Sweden's research institute and innovation partner involved in international cooperation programs with industry, academia and the public sector. RISE is an independent, state-owned research institute that offers unique expertise and over 100 test beds and demonstration environments for future-proof technologies, products and services. In the field of materials and production, RISE KIMAB AB works closely with companies in the steel, process and manufacturing industries. The research focus is on the evaluation of material performance including corrosion and corrosion protection methods.

Acknowledgements

The research project "MACO Pilot" has received funding from the EU budget under the RFCS, Research Fund for Coal and Steel. Many thanks. We would also like to thank all the companies involved in the project, in particular Deutsche Edelstahlwerke, Outokumpu Nirosta, Acerinox S.A.P. (Spain), University of Oviedo (Spain) and RISE KIMAB (Sweden) for their active support and cooperation.

List of symbols and abbreviations

|

Symbol |

Symbol Description |

Unit |

|

Cx |

Acid or metal salt concentration |

g/L |

|

k_x_y |

Polynomial coefficients |

g/L |

|

MGx |

Measured variable (vUS, λel, nD) |

various |

|

nD |

Refractive index |

- |

|

T |

temperature |

°C |

|

vUS |

Ultrasonic velocity |

m/s |

|

λel. |

Electrical conductivity |

mS/cm |

|

Abbreviation |

Abbreviation Description |

|

CPN |

Causal-Probabilistic-Networks |

|

Cx |

Concentration |

|

Cr |

chromium |

|

E-CTFE |

Ethylene-chlorotrifluoroethylene |

|

EDS |

Energy Dispersive Spectroscopy |

|

FFKM / FKM |

Perfluoro rubber / Fluoro rubber |

|

Fe |

iron |

|

FEG-SEM |

Field Emission Gun-Scanning Electron Microscopy |

|

GUI |

Graphical User Interface |

|

H+ |

Hydrogen ions |

|

H2SO4 |

Sulphuric acid |

|

HCl |

Hydrochloric acid |

|

HF HYDROFLUORIC ACID |

Hydrofluoric acid |

|

HNO3 |

Nitric acid |

|

IRS |

Infrared spectroscopy |

|

kx_y |

Polynomial coefficients |

|

Ni |

nickel |

|

PFA |

Perfluoroalkoxylalkane |

|

PTFE |

Polytetrafluoroethylene |

|

PVDF |

Polyvinylidene fluoride |

|

XRF |

X-ray fluorescence analysis |

|

SOM-(NG) |

Self-Organizing-Map-(Neural Gas) |

Literature

[1] Kessler, R.W.: Process analytics - strategies and case studies from industrial practice, Wiley-VHC Verlag (2012)

[2] Industry 4.0: http://www.bfi.de/de/themen/industrie-4-0-und-messtechnik/

[3] Werner, M.; Wolters, R.; Titze, K.; Kozariszczuk, M.: New measuring method for continuous concentration measurement in HNO3-HF mixed acid etchings, Jahrbuch Oberflächentechnik Volume 69, 2013, 304-322

[4] EU-RFCS project Flexible production by multi sensor process control of pickling lines (FLEXPROMUS, RFSR-CT-2010-00017, 7/2010-12/2013)

[5] Werner, M.; Wolters, R.; Kozariszczuk, M.; Hoheisel, G.; Ludwig, J.; Bange, S.: Industrietaugliche Online-Messtechnik zur Konzentrationsüberwachung von HCl-Fe(II)-Fe(III)-Beizbädern, Jahrbuch Oberflächentechnik Volume 72, 2016, 231-254 and Galvanotechnik, Volume 108, 2017, Issues 9 and 10

[6] Rituper, R.: Pickling of metals, Eugen G. Leuze Verlag, Bad Saulgau (1993)

[7] Giordani, P.; Rigamonti, M.; Gasparetto, V.: Stainless steel pickling processes with non-toxic Cleanox (Registered trademark) solutions, Wire Journal International, 39 (2006) 8, 62-66

[8] EU-RFCS project Optimization of the mixed-acid online monitoring and control in stainless steel pickling plants (MACO Pilot, Grant Agreement Nr. 709694, 7/2016-12/2019

[9] Kang, G.; Lee, K.; Park, H.; Lee, J.; Jung, Y.; Kim, K.; Son, B.: Quantitative analysis of mixed hydrofluoric and nitric acids using Raman spectroscopy with partial least squares regression, Talanta, Volume 81, Issues 4-5, June 15, 2010, 1413-1417

[10] Dinger, F.: Indirekt zum Ziel - Inline process analysis with integral measurement methods, Chemietechnik 3 (2006), 22-30

[11] SIROLLCIS FAPLAC technology package for SIROLLCIS pickling lines, company publication, Siemens VAI, Metals Technologies GmbH & Co, Linz, Austria

[12] Monitoring of pickling baths, company publication Anton Paar GmbH (Graz, Austria, www.anton-paar.com)

[13] German patent 10 2004 023 734: Method and device for determining the concentration of at least one metal salt and at least one acid of a pickling acid containing at least one metal salt

[14] Wolters, R.; Schmidt, B.: Improvement of the pickling process by continuous and simple online monitoring of the pickling bath quality, final report on the AiF research project FKZ 14062 N, August 2007, BFI report no. 4.48.129

[15] EU-RFCS project Sensor-based online control of pickling lines (SensorControl, EUR 23872 EN, 07/2004-12/2007)

[16] EU-RFCS project Implementation of sensor based online control of pickling lines (SensorControlPilot, EUR 25320-EN, 07/2007-06/2010)

[17] Process analytics in steel and rolling mills, SensoTech GmbH, stahl und eisen 132 (2012) 5, 94

[18] Park, H.K.; Lee, J.H.; Noh, I.-H.: Development of a concentration measurement system for pickling line control, Journal of Institute of Control, Robotics and Systems, Volume 19, (10) 2013, 891-895

[19] Radiometric measuring systems / Acid management in pickling lines, Company publications, Berthold Technologies GmbH & Co, KG, Bad Wildbad

[20] Critchley, S.; Voges, K.; Mueth, A.; Lehane, B.: Eco pickled surface: an enviromentally advantageous alternative to conventional acid pickling, AISTech 2007, Iron and Steel Techn. Conference, AIST, Proceedings, Vol. 2, Indianapolis, US, May (2007) 7-10, 1-18

[21] Rögener, F.; Buchloh, D.; Schmidt, B.: Sustainable process control in the pickling of stainless steels, Galvanotechnik 98 (2007) 12, 2921-2928

[22] Marx, Th.; Quirmbach, O.; Rituper, R.; Wohnig, I.: New process increases pickling speed and reduces length of pickling lines, MPT International, 3/2015, 132-135

[23] New developments for efficient pickling, SMS group, stahl und eisen 135 (2015) No. 6/7, 135

[24] Process refractometer for concentration measurement in chemically aggressive media, K-Patents AG (Vantaa, Finland, www.buehler-technologies.com)

[25] Process analysis by inline refractometry, company publication FLEXIM GmbH (Berlin, Germany, www.flexim.com/de)

[26] Géron, A.: Practical introduction - Machine Learning with Scikit-Learn & TensorFlow, O'REILLY-Verlag (2017)

[27] https://www.dantecdynamics.com/solutions-applications/solutions/laser-shearography-ndt/

[28] Machón-González, I.; López-García, H.; Bocos-Barranco, I.: Dynamics identification and control of nonlinear MIMO coupled plant using supervised neural gas and comparison with recurrent neural controller, Neural Computing and Applications, 2019, available in:<https://doi.org/10.1007/s00521-019-04195-9> full-text view-only version https://rdcu.be/bEdgbUniOvi 1

[29] Machón-González, I.; López-García, H.: Feedforward Nonlinear Control using Neural Gas Network, Complexity, John Wiley & Sons - Hindawi Publishing Corporation, 2017, available in:<https://doi.org/10.1155/2017/3125073> ISSN 1076-2787

[30] Eduardo-Espitia, H.; Machón-González, I.; López-García, H.; Díaz-González, G.: Proposal of an Adaptive Neurofuzzy System to Control Flow Power in Distributed Generation Systems, Complexity, 2019, ISSN 1076-2787, available in:<https://doi.org/10.1155/2019/1610898>