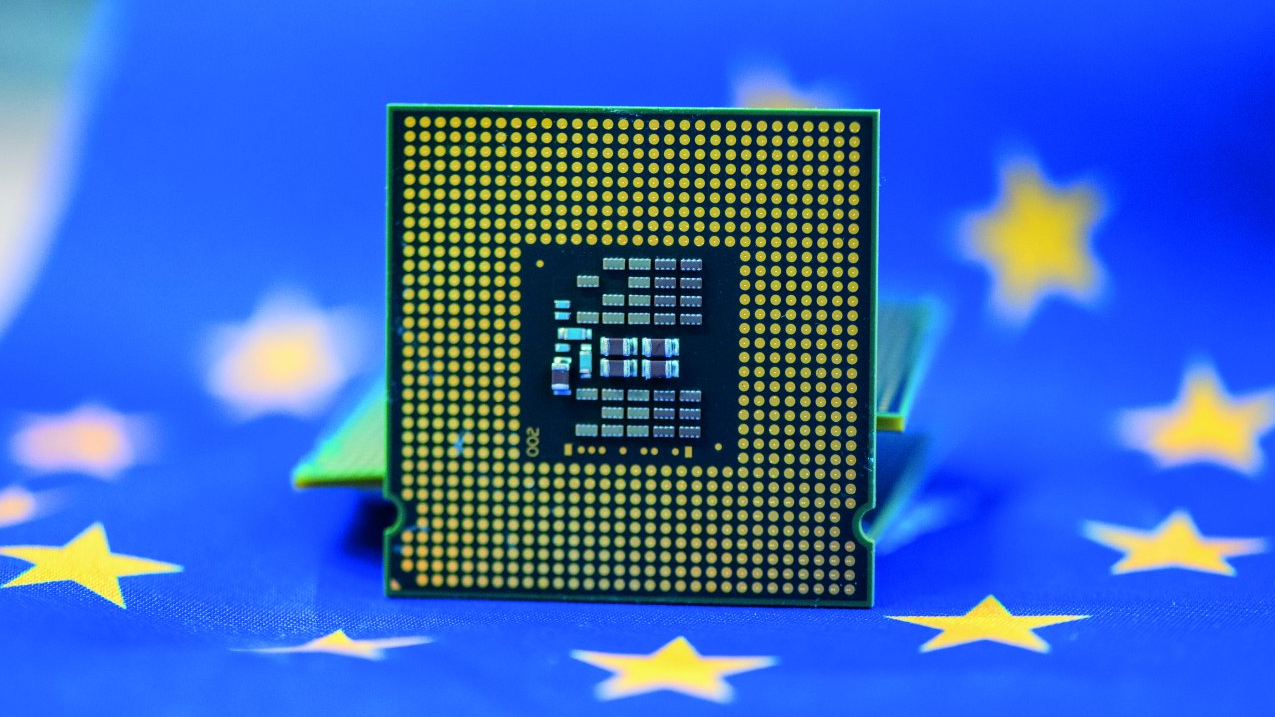

Long-awaited news from Brussels is fueling hopes of a stable upturn in the electronics industry in Saxony and throughout Germany.

Dirk Röhrborn, Silicon SaxonyEU Commission PresidentUrsula von der Leyen recently presented the draft for a separate European chip law that was announced months ago. This 'EU Chip Act' is based on its namesake from the USA. Like the latter, it is intended to significantly improve the competitiveness, market strength and resilience of the domestic - in this case EU-based - semiconductor industry. In return, he promises billions in aid.

Dirk Röhrborn, Silicon SaxonyEU Commission PresidentUrsula von der Leyen recently presented the draft for a separate European chip law that was announced months ago. This 'EU Chip Act' is based on its namesake from the USA. Like the latter, it is intended to significantly improve the competitiveness, market strength and resilience of the domestic - in this case EU-based - semiconductor industry. In return, he promises billions in aid.

Von der Leyern has one major goal in particular: To increase the share of European microelectronics in the global market to 20% by 2030. Back in 2013, the then Competition Commissioner Neelie Kroes had set exactly the same target for 2020. In reality, however, Europe's share had not increased by the end of this period, but had fallen from 10% to 6-7% according to independent market observers. In order to achieve the new milestone, von der Leyen has promised around €45 billion in investments by 2030, among other things. However, this is only partly in the form of additional subsidies. A significant part of the sum is to be paid for by the industry itself. In general, the Commission President also wants to better support the subsidization of new types of chip factories and the development of more branched supply chains.

In initial reactions, politicians and industry representatives welcomed the draft legislation from Brussels. Saxony in particular, Germany's largest microelectronics location, is pleased that the EU is finally giving the semiconductor industry top priority in the midst of the chip supply crisis. However, there were also calls for more speed in the realization of earlier promises.

"The Chip Act is a very good basis for maintaining the economic commitment of the chip industry in Europe and in Silicon Saxony and for enabling new investments, such as those that Intel or TSMC have promised for Europe," explained Dirk Röhrborn, CEO of the Saxon high-tech industry association 'Silicon Saxony'. However, more speed is "urgently needed (...) in order not to fall even further behind in the global competition for investment in new production capacities".

Röhrborn pointed out, for example, that the semiconductor industry is still waiting for a "legally binding commitment" for the special billions for 'Important Projects of Common European Interest' (IPCEI) announced over a year ago. With a view to the new chip law, "the new federal government must present a budget by March that meets the formulated ambitions", demanded the association chairman.

Saxony's Minister President Michael Kretschmer (CDU) sees the EU Chip Act as an important decision "and a great opportunity for Saxony as the most important microelectronics location in Europe". This is because the Chip Act provides for "around 45 billion euros to be made available for the European microelectronics ecosystem by 2030. Research and pilot projects should benefit from this just as much as start-ups." And with a view to hoped-for investment decisions by Intel, TSMC or Samsung for the construction of large semiconductor factories in or near Dresden, Kretschmer emphasized: "The construction of so-called 'megafabs' for the production of microchips is also to be supported." As a reminder, the federal states of Saxony-Anhalt, Bavaria and Saxony in particular have high hopes that these projects by industry giants from the USA, Taiwan or South Korea will soon be built in or near Dresden, Munich or Magdeburg. And this will definitely only happen if the EU and the federal government or the respective federal state subsidize at least 30% of the investment.

Robots in the production environment

Robots in the production environment

The Dresden-based software company Dualis promotes women in IT and Industry 4.0. Here, Sophie Apelmeier (left) Heike Wilson and Evelin Dietrich (right) discuss a visualization In addition to the EU Chip Act and hopes for major investments, well-filled order books are also fuelling the mood in Saxony's high-tech economy: many market researchers and key companies in the sector, such as Infineon and Bosch, assume that the current semiconductor bottleneck in automotive manufacturing and other industries will continue at least until the end of 2022. This may be bad for the German economy as a whole, but it will also ensure full order books in microelectronics and in electronic and electrotechnical manufacturing companies for a long time to come.

The Dresden-based software company Dualis promotes women in IT and Industry 4.0. Here, Sophie Apelmeier (left) Heike Wilson and Evelin Dietrich (right) discuss a visualization In addition to the EU Chip Act and hopes for major investments, well-filled order books are also fuelling the mood in Saxony's high-tech economy: many market researchers and key companies in the sector, such as Infineon and Bosch, assume that the current semiconductor bottleneck in automotive manufacturing and other industries will continue at least until the end of 2022. This may be bad for the German economy as a whole, but it will also ensure full order books in microelectronics and in electronic and electrotechnical manufacturing companies for a long time to come.

However, they will only be able to take full advantage of the pent-up demand if they can solve their own capacity problems. And at the top of the list is the ongoing shortage of skilled workers. In Saxony's software industry alone, there will be a shortage of around 1,000 graduates per year over the next few years, and the semiconductor industry itself has long since exhausted its reserves of skilled workers from the GDR era.

Many companies are therefore currently responding with accelerated post-automation: they are trying to transfer more and more work steps to robots, use autonomous transport systems and find solutions for jobs for which there are simply not enough applicants along other technological paths.

More women in STEM professions

One approach is also to get more women interested in electronics and information technology. This effort has borne fruit over the years, and women's interest in STEM careers is growing - albeit slowly. However, they are still severely underrepresented in many relevant subjects: At TU Dresden, for example, the proportion of women on engineering courses is still below 20%. At Chemnitz University of Technology, the proportion of female students in this sector is similarly low. However, the upward trend is unmistakable: While the proportion of female students at the Chemnitz Faculty of Electrical Engineering, Electronics and IT was only 7.8% in the winter semester of 2008/09, ten years later it was 18.6%.

There are also promising initiatives with the same goal in the economy. In view of the demographic development in Saxony, it has a great interest in tapping into this potential skilled workforce. Entrepreneur Viola Klein is regarded as a pioneer of this trend: she founded the Saxonia Educational Institute in Dresden in the spring of 1990 during the political transition in East Germany, from which a high-performance software company, Saxonia Systems, emerged within a few years. Since then, she has also been campaigning for women in the high-tech industry and has even launched her own prize for talented young female academics in these sectors.

"Increasing digitalization brings with it an increased need for highly qualified specialists and offers a great opportunity for everyone involved to promote people of all genders accordingly," argues Heike Wilson, Managing Director of the Dresden-based software company Dualis GmbH IT Solution. "The shift towards working models that are characterized by mobility and flexibility, for example, makes it possible to achieve a good work-life balance." The proportion of women in the team is now 33% - almost twice as high as in the entire IT sector in Germany (18%). In order to attract more women, Wilson says it relies on an open management culture and flat hierarchies within the company, among other things. It is also important to give employees freedom and encourage creativity.

However, Heike Wilson emphasizes that there are still many hurdles to overcome before the industry can tap into further potential for skilled workers: "There are still too many outdated role models, especially in the IT sector," she says. "In order to achieve greater diversity, we need more 'role models' and education."

Successful female IT entrepreneurs as role models

Key visual of the NeurOSmart projectSuchrole models can be found in the high-tech start-up scene in Saxony: Just recently, for example, the young nanotech company Smartnanotubes Technologies, which is working on an 'artificial nose' based on a nanotube multi-mass sensor in Freital near Dresden, received a million-euro capital injection from the Cottonwood Technology Fund and other venture investors. One of the founders of this successful start-up was Dr. Birte Sönnichsen from the TU Dresden.

Key visual of the NeurOSmart projectSuchrole models can be found in the high-tech start-up scene in Saxony: Just recently, for example, the young nanotech company Smartnanotubes Technologies, which is working on an 'artificial nose' based on a nanotube multi-mass sensor in Freital near Dresden, received a million-euro capital injection from the Cottonwood Technology Fund and other venture investors. One of the founders of this successful start-up was Dr. Birte Sönnichsen from the TU Dresden.

Another example is Packwise: The Saxon IoT company specializes in the digital real-time tracking of packaging containers and has won several awards for its solutions. Here, too, a woman is responsible: founder and Managing Director Gesche Weger has put the company on course for growth.

The Dresden-based AI company Novum engineerING is also headed by a woman. Managing Director Mandy Schipke announced a new, prestigious project just a few days ago: Novum's artificial intelligence (AI) will deeply analyze batteries at Jungheinrich subsidiary JT Energy Systems in order to extend their service life.

The human brain as a model

RISC-V processor IP-Core EMSA5TheFraunhofer lead project NeurOSmart, which aims to develop analog neuromorphic accelerators for better sensors, is also based on artificial intelligence. The human brain serves as a model here, which can make very energy-efficient decisions despite its enormous computing power. Ultimately, NeurOSmart technologies should enable intelligent machines to cope with a complex environment in real time, for example in a factory populated by humans and robots. A total of five research institutes are involved in the project, including the Fraunhofer Institute for Photonic Microsystems in Dresden. Among other things, the IPMS will develop the circuit for the neuromorphic accelerator based on an EMSA5 RISC-V processor core. The Dresden Photonics Institute is also training the accelerator to evaluate data from lidar sensors as efficiently as possible.

RISC-V processor IP-Core EMSA5TheFraunhofer lead project NeurOSmart, which aims to develop analog neuromorphic accelerators for better sensors, is also based on artificial intelligence. The human brain serves as a model here, which can make very energy-efficient decisions despite its enormous computing power. Ultimately, NeurOSmart technologies should enable intelligent machines to cope with a complex environment in real time, for example in a factory populated by humans and robots. A total of five research institutes are involved in the project, including the Fraunhofer Institute for Photonic Microsystems in Dresden. Among other things, the IPMS will develop the circuit for the neuromorphic accelerator based on an EMSA5 RISC-V processor core. The Dresden Photonics Institute is also training the accelerator to evaluate data from lidar sensors as efficiently as possible.

Another topic that the Saxon Fraunhofer Institutes in Silicon Saxony are currently working on is the final wiring of power semiconductors - in line with the demand in the aforementioned Chip Act from Brussels to realize more back-end process steps in Europe again. One of the reasons for this is the increasing demand for power electronics: circuits and components that can withstand high currents and high voltages are needed for electric cars as well as for solar and wind energy systems or for fast-charging smartphone power supplies. In this power segment in particular, many components and circuits are manufactured and later installed in Europe, but in many cases they make a 'detour' to Asia for final assembly and contacting.

ENAS bonds power semiconductors with induced eddy currents

Teams from the Fraunhofer Institute for Electronic Nano Systems (ENAS) in Chemnitz and Chemnitz University of Technology (TUC), together with the Japanese electronics company Shinko, have now developed a new method to 'wire' power electronics chips into complex assemblies much faster than before. They bond the power semiconductors with eddy currents, which they generate using special small induction coils. "This process is revolutionary, especially for manufacturers of power electronics assemblies, as it significantly reduces the duration of joining processes and the thermal influence on all joining components," the Enas specialists are convinced.

This is because the newly developed system can heat the materials that connect chips to circuit boards or to each other very quickly and precisely without heating and damaging the surrounding components. To do this, machines place the chips on base plates called 'direct bonded copper' (DBC) and place silver-containing pastes on the contact points of the circuits. The coils then induce eddy currents into the silver. They can heat the material to 300 °C within five seconds. After cooling down, the chips are permanently electrically connected in the desired circuit (see also the R&T section in the upcoming issue 4 of PLUS).

Transferring microlabs to large-scale production twice as fast

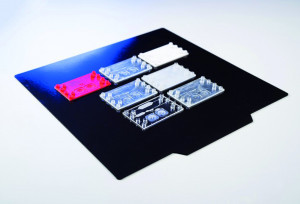

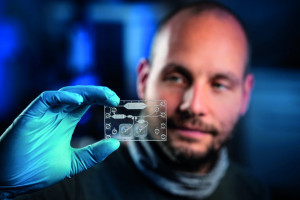

In the SIMPLE-IVD project, design rules are being developed and tested that make it possible to produce in-vitro diagnostics cartridges in a functionally equivalent way using different manufacturing processes In order to bring further value creation steps in electronics and related technology sectors back to Europe from Asia, a more flexible and faster transfer of innovations from local research institutions to commercial exploitation will probably also be necessary. The Fraunhofer Institute for Material and Beam Technology (IWS) in Dresden is currently practising this using a process chain that has become particularly important during the coronavirus pandemic. We are talking about so-called 'lab-on-chip' diagnostic systems, which have already become part of everyday life for blood analyses as well as blood sugar and pregnancy tests. In future, it should be possible to transfer such microlabs to mass production twice as quickly as before. New design rules developed by the IWS together with partners from the East German economy are helping to achieve this. With this new set of rules, it is possible to quickly convert prototype technologies such as mini-diagnostic systems developed in the laboratory using 3D printing to mass production in injection molding machines and similar industrial systems.

In the SIMPLE-IVD project, design rules are being developed and tested that make it possible to produce in-vitro diagnostics cartridges in a functionally equivalent way using different manufacturing processes In order to bring further value creation steps in electronics and related technology sectors back to Europe from Asia, a more flexible and faster transfer of innovations from local research institutions to commercial exploitation will probably also be necessary. The Fraunhofer Institute for Material and Beam Technology (IWS) in Dresden is currently practising this using a process chain that has become particularly important during the coronavirus pandemic. We are talking about so-called 'lab-on-chip' diagnostic systems, which have already become part of everyday life for blood analyses as well as blood sugar and pregnancy tests. In future, it should be possible to transfer such microlabs to mass production twice as quickly as before. New design rules developed by the IWS together with partners from the East German economy are helping to achieve this. With this new set of rules, it is possible to quickly convert prototype technologies such as mini-diagnostic systems developed in the laboratory using 3D printing to mass production in injection molding machines and similar industrial systems.

The teams from research and industry have focused on systems that can be used to evaluate small blood or saliva samples from people who may be ill on the spot. They usually consist of a plastic carrier in which channels for the body fluids are engraved and the highly miniaturized analysis laboratory technology is integrated. They are not only suitable for rapid antigen tests, but also for many other quick analyses in doctors' surgeries, nursing homes and at home: "They will play an important role in the future, especially in personalized medicine," biosystems technology expert Dr. Frank Sonntag from the IWS is convinced. What used to take a lot of time and require large, expensive laboratory equipment can now be analyzed automatically in chip laboratories with tiny patient samples, often within a few minutes.

Florian Schmieder from the Fraunhofer IWS checks the prototype of a complex in-vitro diagnostics cartridge for blood separation. In the SIMPLE-IVD project, the Fraunhofer IWS is working with industrial partners to develop new methods for the cost-efficient production of such cartridgesInrecent years, many research institutes and companies have developed such chip-sized laboratories - but only a few of them have reached market maturity. The major problem has always been the leap from manufacturing in the laboratory to mass production in industrial companies with their typical equipment - for example, injection molding machines instead of 3D printers or roll-to-roll laminating machines instead of manual polymer film layering. "Until now, manufacturers had to start from scratch to scale up to a different process," emphasized Florian Schmieder from the IWS, who coordinated the 'Scalable Microfabrication of Polymeric In-Vitro Diagnostic Systems' (Simple-IVD) project.

Florian Schmieder from the Fraunhofer IWS checks the prototype of a complex in-vitro diagnostics cartridge for blood separation. In the SIMPLE-IVD project, the Fraunhofer IWS is working with industrial partners to develop new methods for the cost-efficient production of such cartridgesInrecent years, many research institutes and companies have developed such chip-sized laboratories - but only a few of them have reached market maturity. The major problem has always been the leap from manufacturing in the laboratory to mass production in industrial companies with their typical equipment - for example, injection molding machines instead of 3D printers or roll-to-roll laminating machines instead of manual polymer film layering. "Until now, manufacturers had to start from scratch to scale up to a different process," emphasized Florian Schmieder from the IWS, who coordinated the 'Scalable Microfabrication of Polymeric In-Vitro Diagnostic Systems' (Simple-IVD) project.

To change this, the project partners developed a computer-based set of rules for new rapid tests and other lab-on-chip systems. These rules ensure that the subsequent transition to mass production processes is already taken into account during development. Conversely, this also makes it easier to switch back to small-series technologies if demand falls. These new design rules already allow the switch between processes such as injection and vacuum molding, multilayer lamination, deep drawing and several additive processes such as plastic 3D printers. "In the future, we will continuously expand the range," announced Schmieder.

OpenRAN targets 5G campus networks

In addition, many projects relating to the 'Industrial Internet of Things' (IIoT) and Industry 4.0 continue to determine the activities in the Dresden-Freiberg-Chemnitz microelectronics triangle. For example, radio technology specialists from Dresden are currently working with other partners to develop special Franco-German campus networks based on 5th generation mobile communications (5G) and manufacturer-independent network architectures based on the OpenRAN principle. According to the Federal Ministry for Economic Affairs and Energy, this involves "open and/or virtualized hardware and software solutions based on an open architecture". The TU Dresden, the Smart Systems Hub Dresden and the Fraunhofer Institute for Integrated Circuits (IIS) in Erlangen are among those involved in this '5G-Opera' project.

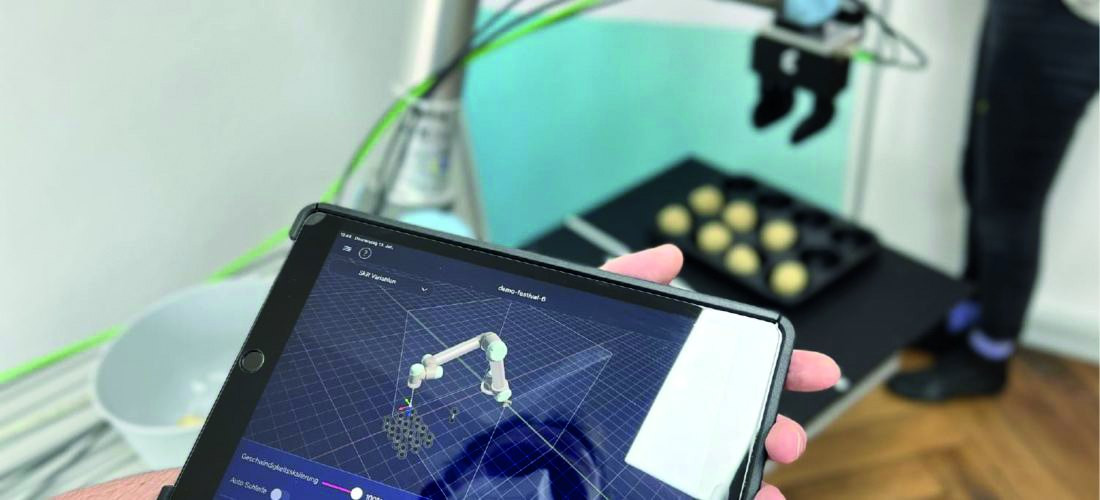

The cobot in the IoT lab can be taught and controlled via tablet

The cobot in the IoT lab can be taught and controlled via tablet

The idea behind the project is to create private radio networks for highly automated Industry 4.0 factories, municipalities, hospitals and other players in Europe that are sealed off from the outside world, thereby making them less dependent on special technology supplies from China and Scandinavia.

The Saxon project partners are on board in part because TU Dresden and its '5G Lab Germany' helped develop the 5th generation of mobile communications at the time. The university spin-off 'Campusgenius', on the other hand, specializes in rapidly deployable 5G campus networks. And the Smart Systems Hub networks numerous players from this technology sector.

Smart Systems Hub expands IoT experimental laboratory

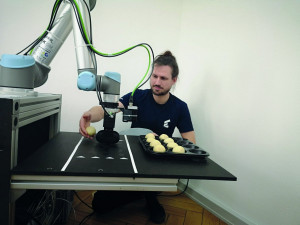

Timon Hitz from Wandelbots teaches a robot to sort dough pieces onto a tray in the Smart Systems Hub's IoT labTheSmart Systems Hub has just expanded its 'IoT Lab' in Dresden in response to the growing interest of industry in the interplay of Industry 4.0 solutions, IIoT, 5G campus networks and hyperautomation. In the 50 square meter laboratory, companies and institutes can now, for example, remotely control robots through clouds using 5th generation (5G) mobile communications. Modular, convertible sensor nodes for machines, robots and other devices are also available there. There are also various gateways between local sensors and the computing technology at the edge of the network (edge clouds) or more distant high-performance data centers for the changing laboratory users. The 'things' in the Internet of Things can be networked via mobile communications, WLAN and other technologies. Particularly interesting: The IoT Lab has its own 5G campus network that is isolated from the outside world - in other words, a network that only the people, machines, robots and mobile devices of the respective lab user can dial into.

Timon Hitz from Wandelbots teaches a robot to sort dough pieces onto a tray in the Smart Systems Hub's IoT labTheSmart Systems Hub has just expanded its 'IoT Lab' in Dresden in response to the growing interest of industry in the interplay of Industry 4.0 solutions, IIoT, 5G campus networks and hyperautomation. In the 50 square meter laboratory, companies and institutes can now, for example, remotely control robots through clouds using 5th generation (5G) mobile communications. Modular, convertible sensor nodes for machines, robots and other devices are also available there. There are also various gateways between local sensors and the computing technology at the edge of the network (edge clouds) or more distant high-performance data centers for the changing laboratory users. The 'things' in the Internet of Things can be networked via mobile communications, WLAN and other technologies. Particularly interesting: The IoT Lab has its own 5G campus network that is isolated from the outside world - in other words, a network that only the people, machines, robots and mobile devices of the respective lab user can dial into.

"With our IoT Lab, we are creating a testing ground for our partners and customers where they can test their own new products and services in practice," explains Hub CEO Michael Kaiser. There is a particular focus on industrial applications and 5G networking. "Numerous players are waiting in the wings and want to use these new technologies for their business development. However, many fear high initial investments and are unsure whether their product ideas will work in practice and pay for themselves. In the IoT Lab, they can test this and combine different networking technologies, cloud connections, interfaces and modern robotics solutions."

One of the first lab users is Dresden-based company Deltec electronics GmbH: "We are currently developing an IoT starter kit to make it easier for our customers to get started with the Internet of Things," reports Managing Director Uwe Wagner. "We want to test this kit in practice here at the Smart Systems Hub." Companies also want to test completely new digital business models in the IoT lab, including industry giants such as SAP, Infineon and Globalfoundries as well as agile start-ups. Acronyms such as RaaS (Robot as a Service) and HaaS (Hardware as a Service) are doing the rounds. The idea behind them: In future, more and more companies will no longer buy their equipment, but will only pay for the time they use the digitally managed service - similar to the user fee models in the software industry or in the shared economy. "This is a thriving market that we want to develop together with the Smart Systems Hub and other partners, such as Objective Partner," says Mirko Paul from software company SAP. "In the IoT Lab, we are creating the necessary reusable environment, a kind of architectural blueprint."

'Playground' for new business models such as rental robotics

One conceivable scenario for this is, for example, factories that cannot utilize their robots themselves around the clock. These companies could then lend these robots to small or medium-sized companies for contract work - such as an assembly job - during 'dead times' and charge for their use on an hourly basis. This RaaS concept would have advantages for both sides: The medium-sized company saves on buying a robot that it will only need from time to time. And the robot factory or robot owner, in turn, can better utilize their machine parks.

However, this RaaS business model only works if the robot can be quickly trained for constantly changing tasks. This is why many of these projects involve the Dresden TU spin-off Wandelbots, which specializes in just such inexpensive and fast no-code robotics. Word of this innovative company's services has now spread: In January, Wandelbots received a hefty €84 million injection of venture capital. The engineers will use the money to adapt their technology to other types of robots. "Their impressive partnerships and outstanding technological expertise have made Wandelbots a leading company in robotics," said Philine Huizing from Insight Partners, explaining the commitment of the Americans in Dresden. "Wandelbots' long-term vision is to unite today's fragmented robotics ecosystem with universal software."

A dedicated AI language model for Europe

And there is another technological race that is driving researchers and engineers in Silicon Saxony and beyond: North America and Asia's huge lead in AI and cloud technologies. The Saxon high-tech scene is therefore taking part in Europe's response to linguistically gifted AI from the USA and China. Together with partners from all over Germany, the Saxons want to develop their own European AI language model called 'Open GPT-X'. Such models enable AIs to understand complex texts, work as robot journalists or support corporate customers, for example. The focus of Open GPT-X is on special AIs that are proficient in European languages and EU data protection. Federal Minister of Economics Robert Habeck is funding this project with almost €15 million from the GaiaX program.

TU Dresden is contributing to this major project via its Center for Information Services and High Performance Computing (ZIH), including Dresden's supercomputer capacities. Together with the Saxon AI research center Scads.AI, the ZIH experts want to "investigate the performance of the language models," announced Scads.AI head Dr. René Jäkel. "In addition to the quality of the predictions of such models, aspects such as parallel efficiency and energy consumption when training the models are becoming increasingly important. The large language models targeted in the project in particular offer great potential for savings."

Sources:

EU Commission, Saxon State Chancellery, Bitkom, Silicon Saxony, Oiger.de, TU Dresden, TU Chemnitz, Fraunhofer Enas, Fraunhofer IPMS, Fraunhofer IWS, BWMi, Smart Systems Hub, SAP, Wandelbots, Novum, Packwise, Deltec electronics, Dualis, Smartnanotubes Technologies, Scads.AI