Industrial Internet of Things-based predictive maintenance detects faults before they occur. This helps to prevent the machine from coming to an unplanned standstill. The IIoT solution can be used for all types of production machines - including electronics production.

"IIoT platforms must be able to be integrated into a wide variety of IT systems" - Michael BreidenbrückerThedigitalization of manufacturing processes results in the networking of the associated machines, production systems and tools. This also has an impact on maintenance. While preventive, predictive maintenance still dominates in many areas today, more favorable technologies are increasingly spreading predictive maintenance concepts. However, machine manufacturers who want to offer their customers added value based on these new maintenance approaches must switch to data-based business models. These use integrated IIoT platforms to collect and analyze data from networked machines and systems.

"IIoT platforms must be able to be integrated into a wide variety of IT systems" - Michael BreidenbrückerThedigitalization of manufacturing processes results in the networking of the associated machines, production systems and tools. This also has an impact on maintenance. While preventive, predictive maintenance still dominates in many areas today, more favorable technologies are increasingly spreading predictive maintenance concepts. However, machine manufacturers who want to offer their customers added value based on these new maintenance approaches must switch to data-based business models. These use integrated IIoT platforms to collect and analyze data from networked machines and systems.

The Industrial Internet of Things (IIoT) is currently turning numerous sectors and industries upside down. In mechanical engineering and electronics manufacturing, the networking of machines and systems generates data with great potential that industrial companies can use to optimize their production processes, for example. Networking allows local machine maintenance to be expanded to include centralized data analysis, which can be used, for example, to determine the expected failure time of a component, such as a seal or a bearing. By comparing the machine and system data recorded during operation with other data, such as idealized models, the software detects faults and malfunctions as soon as they occur. Often long before the malfunction actually occurs. This kind of data-based 'clairvoyance' not only lowers maintenance costs, it also reduces the machine failure rate.

Anticipating and delaying maintenance events

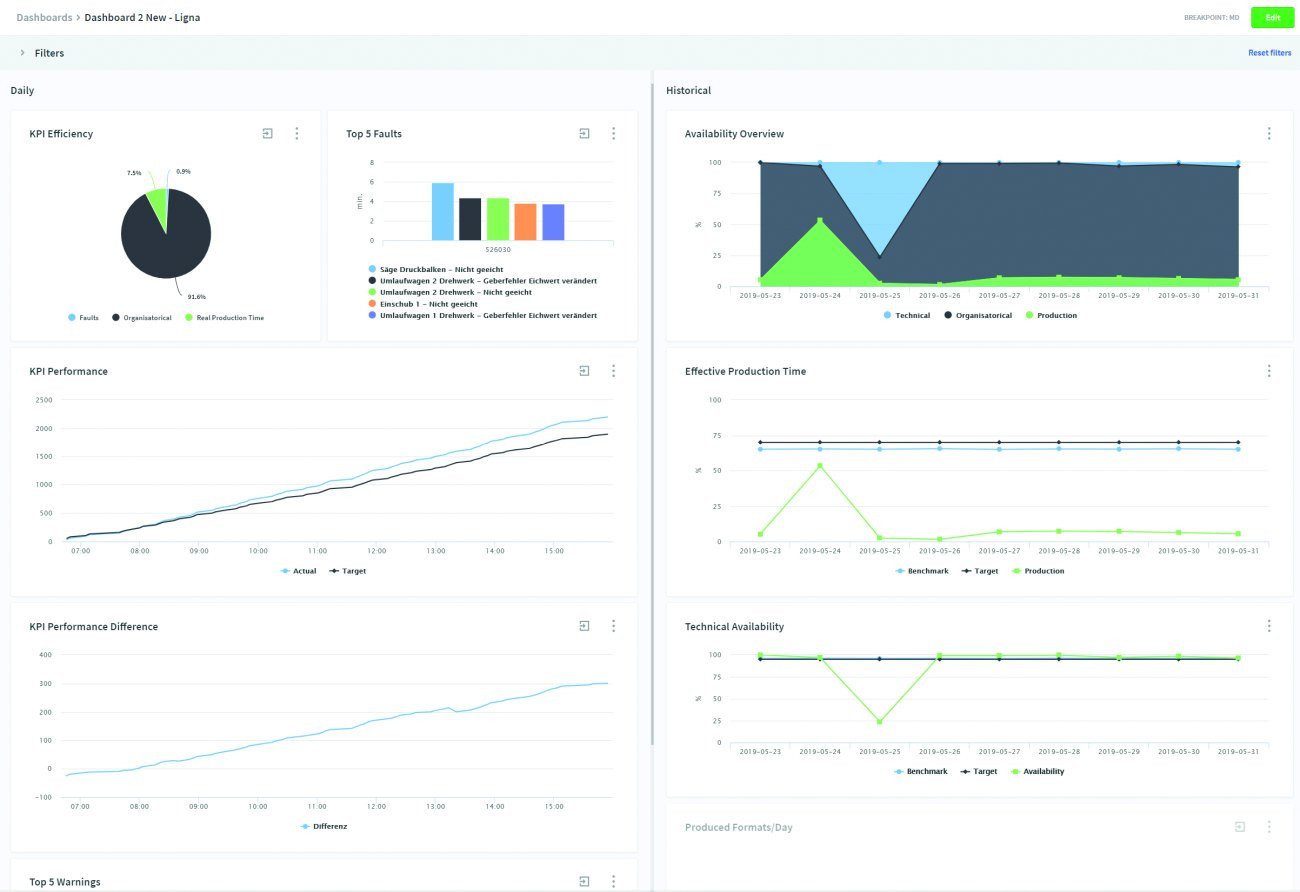

IIoT platforms enable continuous 24/7 monitoring of machines and systems in real time. Intelligent sensors integrated into production machines collect the data generated during production and send it to a cloud-based IIoT maintenance platform. This processes the data and enables trained users to draw conclusions about faults in the system from the recorded noises, speeds or temperatures. In the event of a service call, technicians can use the collected system data to work on troubleshooting in a targeted manner. Using a machine model enriched with historical data, maintenance events can be anticipated and even delayed to an optimum point in time by automatically changing process parameters. This results in reduced maintenance cycles and times.

In electronics production, the probable failure of a machine is determined primarily on the basis of sensor data such as temperature, operating time, speeds, pressure and vibration. Based on AI and ML solutions, it is also possible to automatically postpone a maintenance date. The sensors and systems detect when systems or components are used and stressed more or less frequently than average. They measure and interpret the degree of wear and tear based on unexpected temperature fluctuations, for example, and report this accordingly in order to initiate the early replacement or repair of affected components.

Automatic alarms when the limit value is exceeded

A wide variety of systems and machines, from production plants, wind turbines and aircraft turbines to printing presses, motor vehicles and cranes, can be monitored and maintained worldwide via the internet using predictive maintenance. Communication usually starts in the networked systems, where sensors, measuring stations or probes record and transmit conditions such as temperature, vibrations, capacity utilization or wear. For the evaluation, product and service experts define certain limit values that must not be exceeded or fallen short of. If this is the case, the system automatically triggers an alarm and sends a notification, often by email or text message. For example, a crane manufacturer defines limit values for wind force. If the crane operator attempts to load a ship at a critical wind force above the limit value, this triggers an alarm that automatically reaches the crane operator responsible.

Determining service life using acoustic patterns

Machine manufacturers who want to offer their customers added value with new maintenance approaches must switch to a data-based business model. IIoT platforms provide users with direct and easy access to a system's operating dataAcousticpattern recognition is an analysis method frequently used in predictive maintenance. This makes it possible to determine the service life of a specific part or component, such as a valve, based on changes within an acoustic pattern. Artificial intelligence (AI) and machine learning are used to assign meanings to complex measured values, on the basis of which data scientists can make assessments. For example, the vibrations of a table in a CNC machine can be used to determine the current wear stage of the drill. Is it as good as new, already worn or already worn out? More precise predictions are also possible, such as: "The drill has reached 15 percent of its service life."

Machine manufacturers who want to offer their customers added value with new maintenance approaches must switch to a data-based business model. IIoT platforms provide users with direct and easy access to a system's operating dataAcousticpattern recognition is an analysis method frequently used in predictive maintenance. This makes it possible to determine the service life of a specific part or component, such as a valve, based on changes within an acoustic pattern. Artificial intelligence (AI) and machine learning are used to assign meanings to complex measured values, on the basis of which data scientists can make assessments. For example, the vibrations of a table in a CNC machine can be used to determine the current wear stage of the drill. Is it as good as new, already worn or already worn out? More precise predictions are also possible, such as: "The drill has reached 15 percent of its service life."

Efficient production depends on the functionality of its equipment and technical systems. A technical availability of at least 95% of the possible operating time is considered ideal. As part of predictive maintenance measures, automatic detection of frequently occurring faults can be implemented in the machine. For example, the identification of encoder errors in sensors or deviations in the machine calibration. Thanks to the data-supported, continuous and always up-to-date insight into the system in use, potential for improvement can be identified and implemented at an early stage, for example by comparing it with a digital model, and the availability of the machine can be increased.

However, in order to digitize and appropriately manage production processes, suitable IIoT platforms are required that provide users with direct, uncomplicated access to the operating and status data of a system. For this to work, they must be able to be seamlessly integrated into the IT systems of a wide range of manufacturers. Modern IIoT platforms therefore provide a standardized API that gives users access to the machine data and analysis results. REST or GraphQL-based APIs in particular have proven their worth in this context.

The more successful an IIoT application is, the larger the amount of data that needs to be processed over time. Platforms that are not equipped to manage ever larger volumes of data will quickly reach their limits. When purchasing a platform, companies should therefore also consider its scalability. Their services - from messaging and database services to API services - must be able to run multiple times in parallel so that resources can be seamlessly increased (or reduced).

Providers such as Senseforce offer IIoT platforms based on low code that support the development of processes with visual user interfaces. This means that even users with little IT knowledge can evaluate the status data of their machines and systems

Providers such as Senseforce offer IIoT platforms based on low code that support the development of processes with visual user interfaces. This means that even users with little IT knowledge can evaluate the status data of their machines and systems

IIoT would not be possible without data. But neither would it be possible without trained employees who are familiar with handling and analyzing data. Specialist staff such as data analysts or data scientists are far too rare in medium-sized companies these days, or are often not available at all. However, without employees with qualified data expertise, it will be difficult for companies to achieve added value on the basis of their IIoT platform.

Low-code platforms as a game changer

For this reason, more and more providers are offering IIoT platforms based on low-code. Instead of using traditional text-based programming languages, low-code platforms support the development of processes with visual user interfaces and other graphical modeling methods. This makes it possible for users with extensive machine expertise but little IT knowledge to configure their applications and apps themselves and independently evaluate the status data of their machines and systems without professional programming knowledge. Predictive maintenance based on low code could therefore prove to be a real game changer for mechanical engineering.

About Senseforce

Senseforce offers a platform-as-a-service solution for the implementation and management of industrial IoT projects as an IIoT standard from the plant and mechanical engineering sector. The software allows manufacturers to exploit the full potential of industrial data along the entire value chain, from weak point analysis and predictive maintenance to information on machine and component performance and the development of new data products. Thanks to user-friendly low-code and plug-and-play approaches, the solution can be used across departments in the company and can be integrated flexibly, quickly and transparently into all common IT infrastructures. Author Michael Breidenbrücker is the founder and CEO of the company. Since its foundation in 2016, he and his start-up have developed and established Senseforce as an IIoT standard in plant and mechanical engineering.