In parallel with the growing digitalization of manufacturing processes, predictive maintenance strategies are also increasingly being used in the electronics industry - so-called predictive maintenance concepts. After discussing the advantages and market development of such concepts, this article uses various examples to show what possibilities already exist for their practical application.

The coronavirus pandemic has also brought uncertainties in personnel deployment, fragile supply chains and price and cost increases for German electronics manufacturers. In this situation, talking about future topics such as forward-looking maintenance strategies simply ignores the current concerns of many companies. Instead, the task now is more about keeping the production process running reasonably well.

Nevertheless, the future will not wait. It is likely that the Covid situation will 'normalize' over the course of this year and that companies will gradually be able to return to their usual regime. But what does 'normal' mean when some of the competition is already preparing intensively for the digitalization of their production processes in the direction of Smart Factory or Industry 4.0, despite or precisely because of the pandemic? Both are increasingly emerging as cornerstones for the factory of the future.

Corona has taught us, among other things, that a factory that is equipped with as few 'vulnerable' personnel as possible, as well as machines and processes that are less likely to fail, gets through difficult times better in special situations. This speaks for a smart factory and therefore also for smart predictive maintenance. Even in difficult times, electronics manufacturers are still required to meet the demand for high-performance, high-quality electronics at market-driven prices as closely as possible.

Prevailing situation

Oliver Kraus, experienced SMT Solutions Manager at ASM PT, outlined the prevailing situation in maintenance management in an interview in [1] last September: 'Despite all the differences, it is noticeable that even in large and well-organized companies, it is often still cumbersome and time-consuming to work with a large number of manufacturer-specific tools and maintenance calendars. In addition, computerized Excel lists and maintenance folders with paper printouts of them - in other words, a lot of classic 'paperwork' - are still the order of the day. This makes maintenance rigid, confusing and difficult to control. It is not easy to maintain an accurate overview and coordinate necessary maintenance activities with ongoing production or pending orders. As a result, the company only reacts and stubbornly follows the manufacturer's maintenance intervals. The same applies to the maintenance work itself: many instructions are only available on paper and the documentation of maintenance work is cumbersome and time-consuming.

The maintenance intervals specified by manufacturers today are usually general specifications that are not based on the actual stress and degree of use of the machines at the customer's premises. Maintenance is therefore often carried out unnecessarily too early. Ideally, however, maintenance should be based on the load, performance and condition of production.

Predictive maintenance

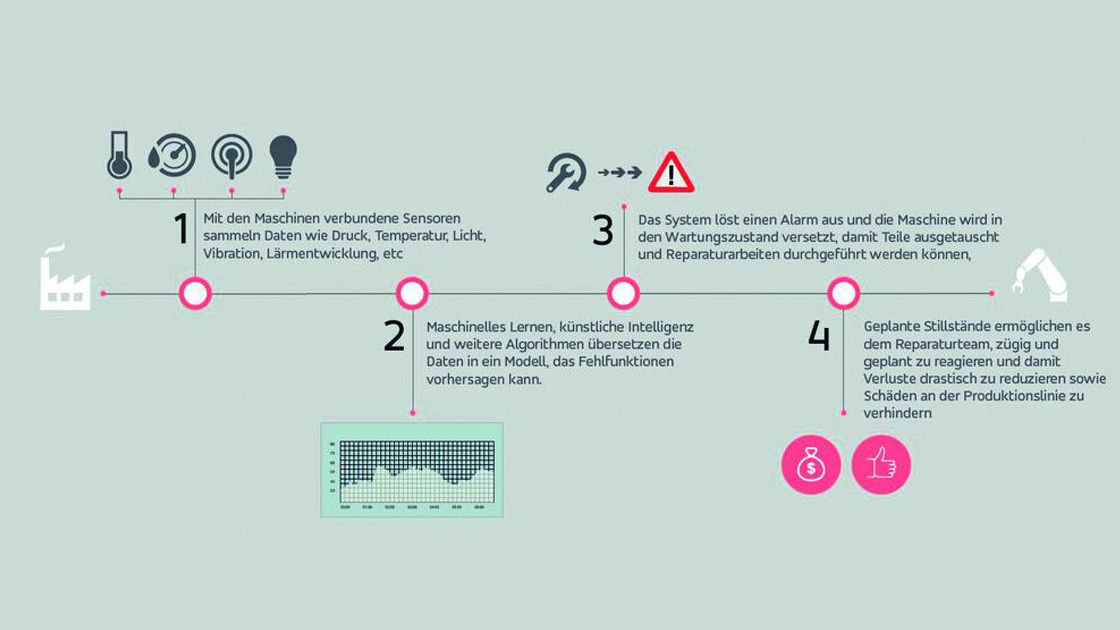

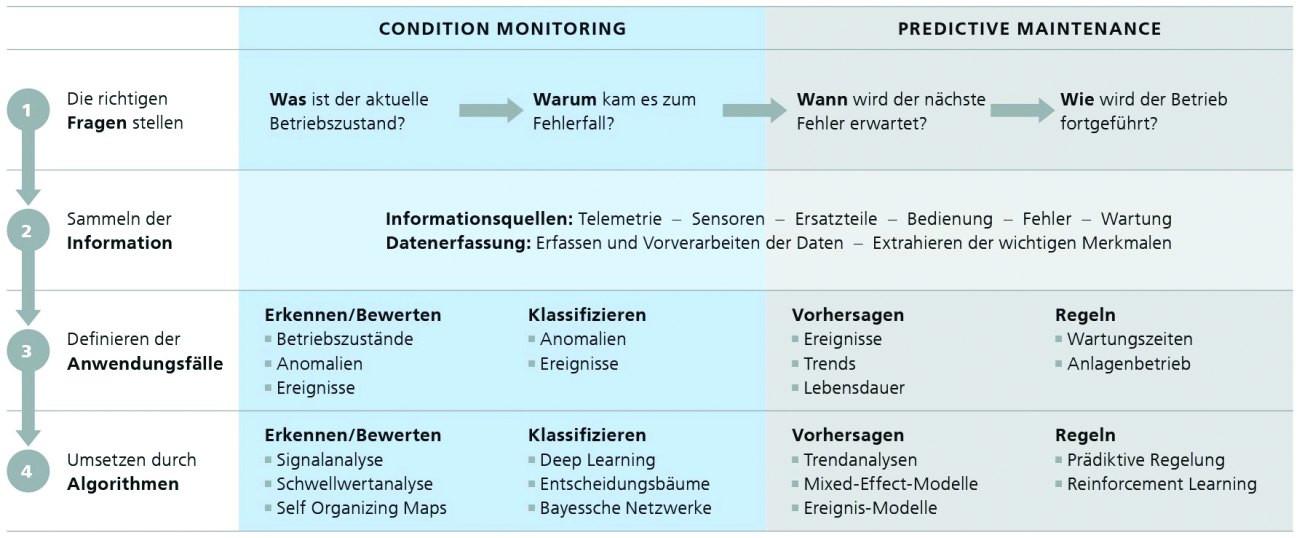

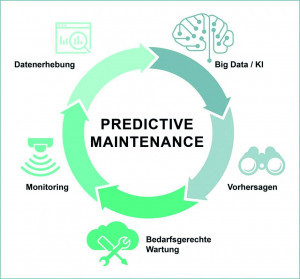

The forward-looking, smart approach of predictive maintenance (PM) allows maintenance to be carried out when it is really necessary and when the impact on ongoing production as well as personnel and material costs are minimized. Condition monitoring (CM) is an intelligent, digitalized preliminary stage aimed at PM and also already increases machine availability through better identification of suitable maintenance times. It contributes significantly to quality improvement and therefore to higher yields. However, there are evolutionary differences between CM and PM:

Condition monitoring evaluates trends from sensor data of the machines, recognizes critical events and operating states with high wear potential. Events and resulting faults are classified and evaluated. Critical events or undesirable operating states can be eliminated immediately by reacting quickly to prevent cost-intensive consequential damage. Downtimes are reduced as service technicians, spare parts and logistics can be provided in a targeted manner thanks to appropriate diagnostics.

Fig. 2: Differences between condition monitoring and predictive maintenance

Fig. 2: Differences between condition monitoring and predictive maintenance

Predictive maintenance forecasts the risks of undesirable operating states and events based on the empirical values gained from condition monitoring [2]. These forecasts enable demand-oriented planning of service and maintenance actions. They are created for both individual systems and system parks. Ideally, predictive maintenance maximizes availability and provides early information for targeted maintenance activities(Fig. 1, 2).

Great potential for rationalization

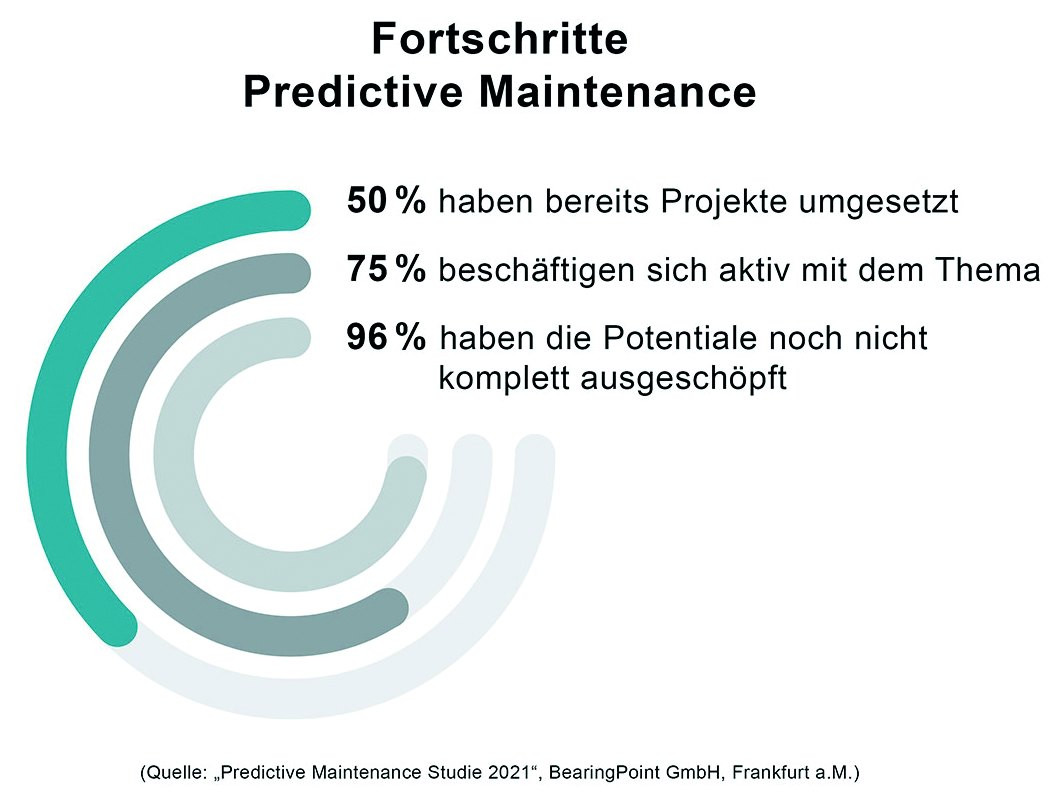

ASM SMT Solutions presents the results of the 'Predictive Maintenance Study 2021' conducted by BearingPoint GmbH Frankfurt/Main at [3]. ASM SMT Solutions is a business segment within the ASM Pacific Technology (ASM PT) Group and bundles the Group's global SMT business. The aim is to develop networked, integrated solutions for SMT production, their realization and implementation at electronics manufacturers worldwide. For this reason, the topic of 'digitalized predictive maintenance' is one of the company's core tasks.

Fig. 3: Progress in the use of predictive maintenance as of 2021

Fig. 3: Progress in the use of predictive maintenance as of 2021

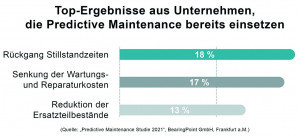

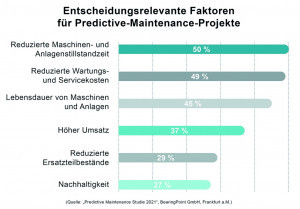

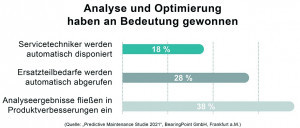

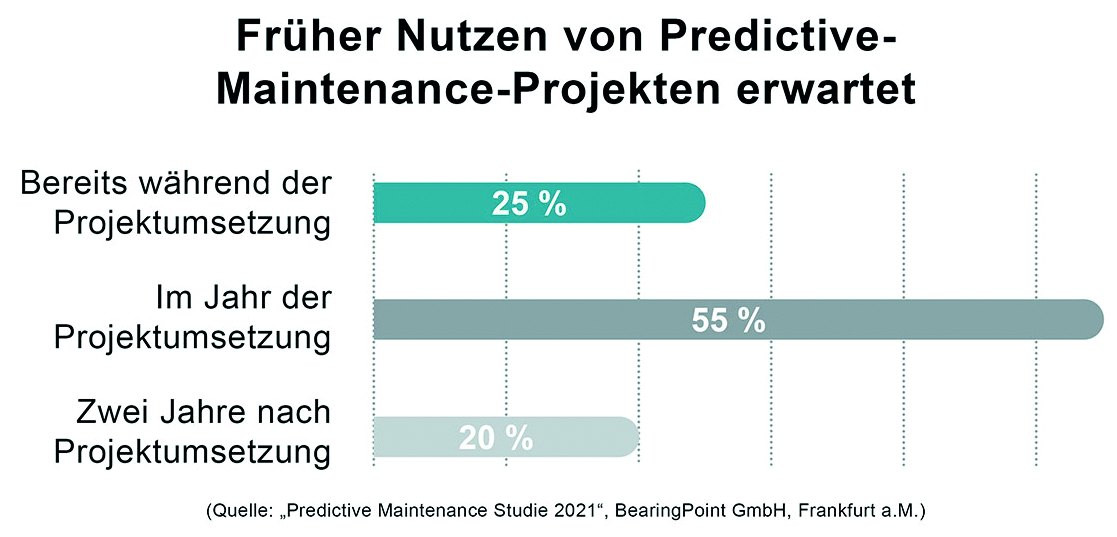

According to the experts and companies surveyed during the preparation of the study, around 50% of companies have already implemented predictive maintenance (PM) projects(Fig. 3). However, the fact that 96% of respondents have not yet exhausted the potential proves that this development is still in its infancy. Companies that are already using PM reported that downtimes, for example, have been reduced by an average of 18%(Fig. 4). Maintenance and repair costs were reduced by 17%. According to the respondents, the reduction in machine and system downtimes and the reduction in maintenance and service costs played the main role in preparing for PM(Fig. 5). It was also stated that the service life of machines and systems was increased by an average of 45%, which is not insignificant. It is also interesting to see how the scheduling of service personnel and the ordering of spare parts can be improved(Fig. 6).

The investigations carried out as part of the study also revealed that a relatively short time horizon can be expected after the start of PM work until the first successes are achieved. They can already be seen to some extent during or in the year of project implementation(Fig. 7). In summary, the main advantages of PM according to the study are

- Flexible, needs-based service intervals

- Fewer faults, higher availability of machines and systems

- More efficient maintenance and documentation

- Software that monitors machines via sensors and thus detects trends and anomalies - long before they lead to faults

According to expert estimates, the consistent use of predictive maintenance can prevent up to 70% of all unplanned machine and system failures. At the same time, the coordinated timing of maintenance work and optimized scheduling of technicians can save a good third of the time and effort currently required.

Fig. 7: Time horizon for the first positive results of PM to become visible

Fig. 7: Time horizon for the first positive results of PM to become visible

What do market forecasts say?

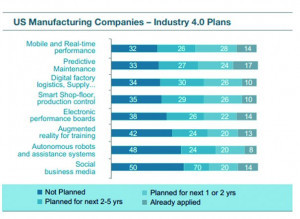

Fig. 8: US companies' plans for the transition to Industry 4.0Thisclear benefit of PM is reflected in optimistic market forecasts. For example, according to the Predictive Maintenance Market Report 2021-2026 by Hamburg-based IoT Analytics, the market for predictive maintenance was worth USD 6.9 billion last year. It is expected to grow to $28.2 billion by 2026 according to the 183-page report published in April 2021 [4]. The market is defined as the cumulative annual PM technology spend of companies worldwide that implement PM solutions.

Fig. 8: US companies' plans for the transition to Industry 4.0Thisclear benefit of PM is reflected in optimistic market forecasts. For example, according to the Predictive Maintenance Market Report 2021-2026 by Hamburg-based IoT Analytics, the market for predictive maintenance was worth USD 6.9 billion last year. It is expected to grow to $28.2 billion by 2026 according to the 183-page report published in April 2021 [4]. The market is defined as the cumulative annual PM technology spend of companies worldwide that implement PM solutions.

To compile the analysis, 280 companies from various industry sectors were surveyed. These included ABB, Amazon Web Services, Aspen Technologies, Augury, AVEVA, Cisco, GE, Google, HPE, IBM, LeanBI, MachineMetrics, Microsoft, Nanoprecise SC, PARC, PTC, Reliability Solutions, SAP, Seeq, SKF, Senseye, Siemens and many other companies active in the electronics and software sector. IBM, Siemens, SAP, Microsoft, General Electric and Bosch are among the leaders. It can therefore be assumed that the electronics manufacturing industry has been taken into account accordingly and that the information in the study can generally be applied to it.

The company ResearchAndMarkets has been offering the study 'Predictive Maintenance Market by Component, by Deployment, by Technique, by Stakeholder, by Industry Vertical - Global Opportunity Analysis and Industry Forecast, 2021 - 2030' since October 2021 [5]. The global market size for predictive maintenance was estimated at $4.45 billion in 2020. It is expected to reach $64.25 billion by 2030 and grow at an annual rate of 31% from 2021 to 2030. These figures correlate with the values published by IoT Analytics, at least with regard to the development intensity of PM.

While the absolute values mentioned above and their origins may be questioned, the charts from IoT Analytics show that expenditure will increase slightly exponentially from 2021 to 2026. This means that by 2030, the figures could rise again to an order of magnitude of perhaps $50 billion, i.e. a sevenfold increase compared to 2021. In principle, this is not to be doubted, as PM is an integral part of the digitalization process in the context of Industry 4.0 and that is the future.

For its study 'Digital Factories 2020 Shaping the Future of Manufacturing' from April 2017, management consultants PWC surveyed a large number of companies on the status and strategies for the digitalization of their factories. The companies surveyed included Philips, Nokia, Bosch-Rexroth and Fujitsu. The results showed that 91% stated that investments in digitalization had already been made at the time, albeit to varying degrees and in different sectors. The companies were asked to provide information on the status of their application in 14 predefined sectors of digitalization (predictive maintenance, connected factory, integrated planning, digital twin of the factory, digital twin of the product, etc.). This revealed that 28% of respondents were already working on PM and that in five years, i.e. 2022, 66% of respondents would already be doing so. PM was at the top of the 14 sectors and thus took first place in the complex process of digitizing factories [6].

A similar insight into the status of US companies in preparing for Industry 4.0, including PM, is provided by a graphic from the US consulting firm Capgemini(Fig. 8). Although it is from a 2017 study, it shows that, assuming that it is already 2022, around 60% of the US companies surveyed have already introduced PM or are in the process of doing so. At least that is the author's hypothesis. Here, too, PM is at the top of the list of sectors shown in the chart.

![Abb. 9: Entwicklungsstufen der Predictive Maintenance gemäß PWC [5] Abb. 9: Entwicklungsstufen der Predictive Maintenance gemäß PWC [5]](/images/stories/Abo-2022-03/plus-2022-03-0069.jpg) Fig. 9: Development stages of predictive maintenance according to PWC [5]

Fig. 9: Development stages of predictive maintenance according to PWC [5]

From subjective to objective predictive maintenance

Fig. 10: Comprehensive sensor technology in machines, big data, AI and algorithms are the core elements for successful predictive maintenance (above)In another study from June 2017, 'Predictive Maintenance 4.0 - predict the unpredictable', PWC focused specifically on the current status of predictive maintenance and divided it into four development stages [7]:

Fig. 10: Comprehensive sensor technology in machines, big data, AI and algorithms are the core elements for successful predictive maintenance (above)In another study from June 2017, 'Predictive Maintenance 4.0 - predict the unpredictable', PWC focused specifically on the current status of predictive maintenance and divided it into four development stages [7]:

- Level 1: Visual inspections - regular physical. The conclusions are based solely on the inspector's knowledge and expertise

- Level 2: Instrument inspections - regularly complex. Conclusions are based on a combination of the inspector's experience and instrument readings

- Level 3: Real-time condition monitoring: continuous real-time monitoring of objects with alerts based on predefined rules or critical conditions (condition monitoring)

- Level 4: PM 4.0 as continuous real-time monitoring of objects with warnings, based on prediction techniques such as regression analyses by collecting and evaluating large amounts of data, e.g. using AI

At present, levels 1 and 2 still dominate as the long-established form of predictive maintenance. They prove that the latter is nothing new in itself. What is new now, however, is the gradual transition to a completely new quality of PM as part of the digitalization of companies and company networks, i.e. levels 3 and 4. The application of big data analytics in maintenance represents the fourth level of predictive maintenance, referred to as PdM 4.0 in Figure 9. This involves predicting future failures in systems. It is ultimately the most effective preventive tool based on progressive analysis techniques. At its core is the collection and processing of big data on technical condition, usage, environment, maintenance history and experience with similar equipment elsewhere, as well as correlating other factors(Fig. 10). The transition from Level 3 to PdM 4.0 is at the heart of the work already underway in many companies.

Predictive maintenance is complex

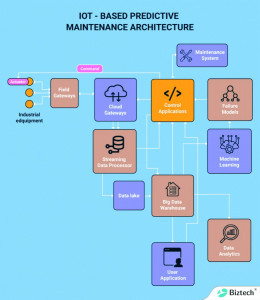

Figure 10 shows PM in a highly simplified form. In reality, the transition to predictive maintenance in the context of Industry 4.0 requires a rather complex architecture with many different building blocks, as demonstrated in the example in Figure 11. The path to completing this architecture is an evolutionary process.

Fig. 11: The basis for predictive maintenance in the context of Industry 4.0 is a complex structure of different combined components (below)Wireless and wired signal transmission, inexpensive low-cost MEM sensors, cloud computing, edge computing and powerful analysis algorithms for machine learning form the starting point. Actuators, motors and drives are equipped with sensors that collect the data, filter it through gateways and then transmit it to the cloud or the company's data center for processing. In the monitoring center, this data is merged with other information from the monitoring of technological steps such as multi-stage AOI to form an overall picture.

Fig. 11: The basis for predictive maintenance in the context of Industry 4.0 is a complex structure of different combined components (below)Wireless and wired signal transmission, inexpensive low-cost MEM sensors, cloud computing, edge computing and powerful analysis algorithms for machine learning form the starting point. Actuators, motors and drives are equipped with sensors that collect the data, filter it through gateways and then transmit it to the cloud or the company's data center for processing. In the monitoring center, this data is merged with other information from the monitoring of technological steps such as multi-stage AOI to form an overall picture.

To ensure that the right data is collected and the right data sets are analyzed, the predictive models are regularly updated and tested for accuracy. If the result deviates from the expected one, the models are revised, retrained and retested until they work perfectly. In addition, usage history data, service information and model specifications can be used to improve the asset's prediction results.

Before machine learning (ML) is used in practice, exploratory analyses must be carried out to help select the most suitable machine learning algorithm by evaluating technical assumptions. The author knows from his own family circle how much the quality of models and learning algorithms can make AI results either useless or very useful. In other words, the quality of the models and algorithms is crucial for the successful introduction of PM and requires the utmost attention.

After all, software for ML should recognize patterns, identify abnormal behavior in the context of variable industrial environments, understand long-term trends and avoid unwanted events.

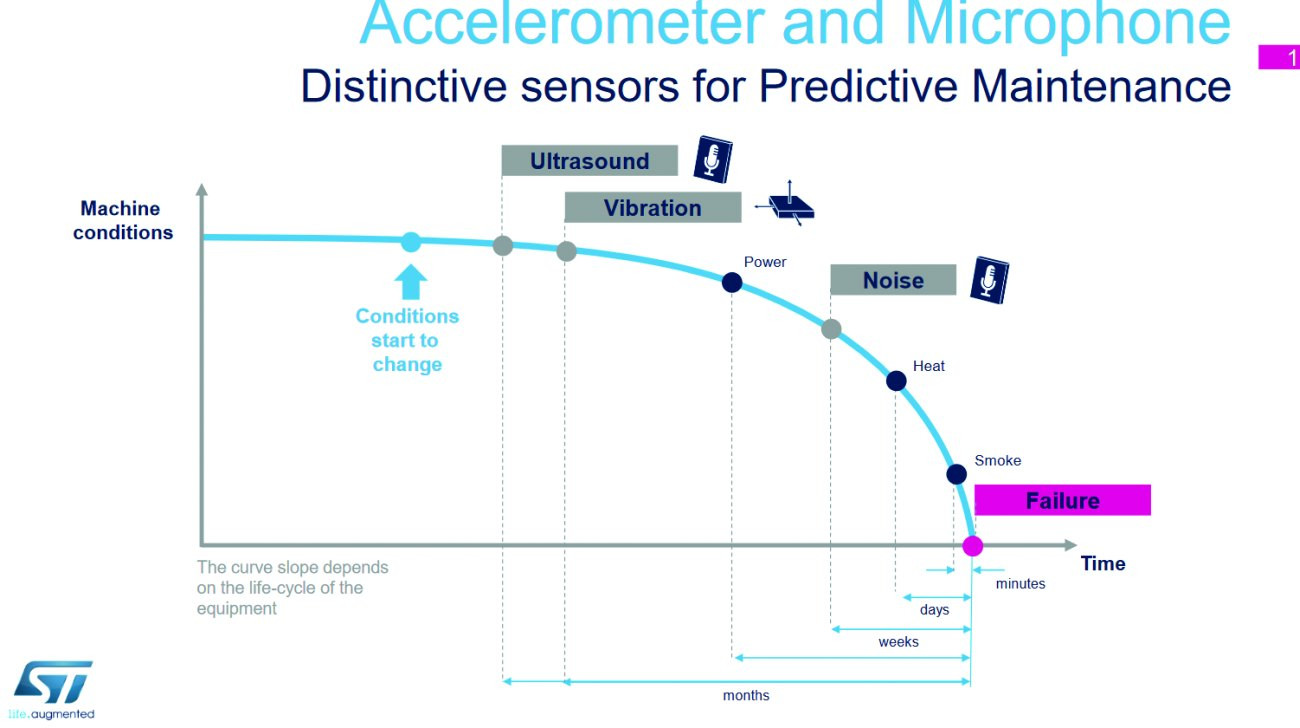

One example of an analysis method frequently used in predictive maintenance is acoustic pattern recognition. Based on changes within an acoustic pattern, the service life of a specific part or component, such as a valve or nozzle, can be determined. Both components are part of various pieces of equipment for PCB production. Artificial intelligence and machine learning are used to assign meanings to complex measured values, on the basis of which data scientists can make assessments. For example, the vibrations of a table in a CNC machine can be used to determine the current wear stage of the drill. Is it as good as new, already worn or already worn out? More precise predictions are also possible, such as: "The drill has reached 15 percent of its service life." This method can be used for mechanical PCB drilling machines, for example.

Fig. 12: Sensitive sensors are at the heart of machine monitoring

Fig. 12: Sensitive sensors are at the heart of machine monitoring

To monitor for abnormalities in machines, semiconductor manufacturers such as ST are providing increasingly sophisticated sensors, including accelerometers and microphones for ultrasound, vibration and noise(Fig. 12).

Data analyst bottleneck

The more successful a PM application is expected to be, the greater the amount of data that needs to be processed over time. Without trained employees who are familiar with handling and analyzing data, PM would not be possible in companies, but neither would it be possible without data. According to reports from medium-sized companies, there are far too few specialist staff such as data analysts or data scientists available today. Often they are not available at all. However, without employees with qualified data expertise, it will be difficult for companies to achieve added value on the basis of their IIoT platform [8].

Gradual transition to predictive maintenance PdM 4.0 in line with the situation

1] states that, for various reasons, PM cannot yet be implemented comprehensively and consistently in many production facilities, but must be implemented step by step. In order to close data gaps here, appropriate systems and sensors must be installed, hardware prepared and empirical values for the interpretation of sensor data collected. Corresponding AI solutions are being developed in many places.

ASM, for example, has been providing sensor signals from its various machines for many years. Up to 35 sensors per unit were already installed in 2021. They provide data on voltages, currents, temperatures and much more. The manufacturer is continuously expanding this area, as the ability to read sensors via open interfaces is the key to seamless predictive maintenance. IPC CFX is establishing itself as a powerful interface for vertical data communication - open, standardized and independent of manufacturers.

In ASM's opinion, however, there cannot and will not be a standardized 'off-the-shelf' solution for all production facilities. When and to what extent sensors, AI and big data technologies should be used depends heavily on the individual situation of an electronics production facility. Not all evolutionary stages of predictive maintenance will be economically viable everywhere and for all machine components. This is why some company surveys on PM simply give the answer 'No'.

Fig. 13: IPC CFX is establishing itself as a powerful interface for vertical data communication - open, standardized and independent of manufacturers

Fig. 13: IPC CFX is establishing itself as a powerful interface for vertical data communication - open, standardized and independent of manufacturers

However, companies can make preparations and take the important first steps. For example, they need future-proof asset management software that supports the monitoring of machines and the central control of maintenance and servicing activities for all machines. Even today, maintenance costs and maintenance times can be significantly reduced through such central control and the digitalization of all maintenance instructions and aids.

ASM Factory Equipment Center for assembly production

Fig. 14: ASM Factory Equipment Center can be used on various mobile devices ASM Assembly Systems GmbH & Co. KG has been offering ASM Factory Equipment Center, a modular, powerful, integrated software solution for company-wide asset and maintenance management, as part of its condition monitoring since 2021. It not only applies to DEK printers or Siplace placement systems. Thanks to the modularity of its components, it can be flexibly adapted to the company.

Fig. 14: ASM Factory Equipment Center can be used on various mobile devices ASM Assembly Systems GmbH & Co. KG has been offering ASM Factory Equipment Center, a modular, powerful, integrated software solution for company-wide asset and maintenance management, as part of its condition monitoring since 2021. It not only applies to DEK printers or Siplace placement systems. Thanks to the modularity of its components, it can be flexibly adapted to the company.

Scheduling, task distribution, provision of maintenance instructions and checklists, tracking of sensor data and monitoring of the systems, documentation of maintenance and servicing are carried out centrally for all machines, conveyors, production tools and placement heads - also for equipment from other manufacturers and for areas outside SMT production. As part of the comprehensive feeder management, a separate maintenance and fault history with real-time tracking is kept for each individual conveyor [9]. Their measured values can also be called up in real time with just a few clicks on the machine's digital twin.

An open and powerful interface that is accepted and offered across all areas is required so that the data can be transferred from machines from a wide range of manufacturers. These can be open interfaces such as the Hermes standard or IPC-CFX.

In ASM's opinion, the independent IPC CFX standard is currently the most promising solution in the electronics industry for recording and evaluating data from heterogeneously assembled SMT lines. This is why ASM Factory Equipment Center uses IPC CFX. This means that machines from other manufacturers and their sensor signals can also be integrated All maintenance process steps are covered and partially automated in ASM Factory Equipment Center as workflows in the software - from central planning to automated documentation. With just a few clicks, status information on all machines can be called up, pending tasks can be automatically distributed to service technicians by email and information on required wear or spare parts can be retrieved. It is also possible to access electronic checklists for carrying out the necessary maintenance work. Technicians are supported at all times by multimedia instructions to save time and minimize errors during maintenance work. The electronic maintenance reports are saved without any additional work. This also includes measurement logs from some tools that are used to verify machine capabilities. For example, ASM tools such as the X-Feeder Verification Station or the Head Care Station can be connected.

The software is accessed via the Internet browser released in the application and can therefore also be accessed very easily and flexibly via mobile devices such as smartphones or tablets(Fig. 14). ASM is breaking new ground with its license model: renting instead of buying according to demand. The amount of the rental license for ASM Factory Equipment Center scales with the number of assets. Transparent operating costs replace investments with lengthy depreciation.

Predictive services from Siemens for benefit separators

One of the PM solutions that Siemens offers the electronics industry as part of Digital Enterprise Services is geared towards depaneling machines for printed circuit boards. The depaneling process produces fine dust that accumulates on the spindles. This dust can hinder the continuous rotation of spindles or, in the worst case, stop it. Instead of planning fixed maintenance intervals, predictive services can be used to analyze the spindle flow and check for anomalies. As a result of the evaluation with AI, solid process data and indications of error sources are obtained. Staff are informed promptly and proactively about critical conditions. Siemens aims to support the digital transformation of companies with the three modules Assessment, Connectivity and Analytics [10].

Monitoring and predicting cable wear

Fig. 15: Etherline Guard from Lapp for monitoring data cables So far, this article has mainly focused on monitoring the function of the machines themselves. However, monitoring the wear and tear of cables, whether for power or data supply, is just as important. The German company U. I. Lapp GmbH announced the launch of Etherline Guard, an innovative monitor for data cables, at the end of 2021(Fig. 15). This is designed to monitor the service life of a data line at risk of failure in Ethernet-based automation technology networks. It is particularly advantageous and cost-saving for cables with highly dynamic, demanding movements at high speeds and strong torsion if the connection systems are monitored. This is based on data that is determined from the physical properties of the data transmission using a sensor system. The real-time status display makes it possible to recognize the wear limit of a cable and plan the optimum replacement time in advance [11].

Fig. 15: Etherline Guard from Lapp for monitoring data cables So far, this article has mainly focused on monitoring the function of the machines themselves. However, monitoring the wear and tear of cables, whether for power or data supply, is just as important. The German company U. I. Lapp GmbH announced the launch of Etherline Guard, an innovative monitor for data cables, at the end of 2021(Fig. 15). This is designed to monitor the service life of a data line at risk of failure in Ethernet-based automation technology networks. It is particularly advantageous and cost-saving for cables with highly dynamic, demanding movements at high speeds and strong torsion if the connection systems are monitored. This is based on data that is determined from the physical properties of the data transmission using a sensor system. The real-time status display makes it possible to recognize the wear limit of a cable and plan the optimum replacement time in advance [11].

Limtronik on the way to predictive maintenance

Research by the author into SMEs in the electronics production sector that are already actively involved in condition monitoring or predictive maintenance was not very successful in the specialist media. This shows that the path to PM via CM appears to be arduous and is only being taken slowly, step by step. This is where Smart Electronic Factory e. V. (SEF) comes in, an Industry 4.0 initiative for German SMEs and a flagship project. SEF is an information and demonstration platform for Industry 4.0. The evaluation environment has been implemented in a real electronics factory, namely the EMS service provider Limtronik, since 2017. In March 2021, the association announced that applications will be designed, tested and validated in a total of three real electronics factories - Limtronik, EGO and KEBA.

Various software and hardware manufacturers as well as university institutions are actively involved in the initiative. The central objective is to implement Industry 4.0 scenarios, with a focus on solutions suitable for SMEs, in the real production of companies. This also includes predictive maintenance solutions [12].

Limburg-based EMS service provider Limtronik already reported in a press release in 2017 that the company is on its way to becoming a digitalized factory or PM in the medium term by participating in SEF [13]. At the time, it was working with partners such as the West Saxon University of Applied Sciences in Zwickau to develop various proof of concepts for smart manufacturing.

In the Smart Electronic Factory, Industry 4.0 applications are tested in practice and brought to market maturity. Together with members of the SEF and other cooperation partners, Limtronik developed various proof of concepts in 2017, such as a data mining project. This made Limtronik a pioneer in the EMS sector when it comes to digitalization and Industry 4.0.

The POC data mining project is being implemented in collaboration with the partners mentioned above. Data provided by the assembly process or Manufacturing Execution System (MES) is recorded, validated and checked for plausibility in the project. The aim is to expand the depth of quality, process and machine data collection in order to go further in the direction of predictive maintenance. One of the data suppliers was a Fuji pick-and-place machine.

It looks like SEF is gradually pushing ahead with its work on predictive maintenance. In July 2021, Limtronik announced that the company had also taken its internal communication system to a new level. In collaboration with Ascom DACH, a solution was developed and installed that, for example, automatically displays faults and failures on mobile devices and supports predictive maintenance processes.

At the Hanover Fair in April 2021, the Smart Electronic Factory presented practical examples of vertically and horizontally networked production at Limtronik to demonstrate how digitalization can also be advanced in other companies. This should motivate SMEs to digitize. It seems that the additional burdens caused by the coronavirus pandemic have significantly slowed them down.

References:

[1] www.all-electronics.de/elektronik-fertigung/zukunftsziel-predictive-maintenance-110.html

[2] www.itwm.fraunhofer.de/de/abteilungen/sys/maschinenmonitoring-und-regelung/predictive-maintenance-instandhaltung-machinelearning.html

[3] www.asm-smt.com/de/predictive-maintenance/

[4] https://iot-analytics.com/product/predictive-maintenance-market-report-2021-2026/

[5] www.businesswire.com/news/home/20211022005161/en/

[6] www.pwc.de/de/digitale-transformation/der-mensch-wird-in-der-digitalen-fabrik-nicht-ueberfluessig.html

[7] www.pwc.nl/nl/assets/documents/pwc-predictive-maintenance-4-0.pdf

[8] https://senseforce.io

[9] www.asm-smt.com/de/aktuelles/presse/software-fur-das-fabrikweite-asset-und-maintenance-management

[10 ] www.siemens.com/predictive-services xml-ph-